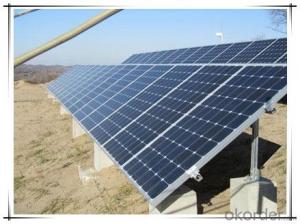

Best Quality Solar Bracket

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 watt/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Introduction

Solar panel bracket is designed for large commercial solar plant. It is suitable for frame or frameless solar modules. Because of the concise design, the material of this panel bracket is very economical. So it is very competitive in this market.

Specification

1.Material:prefab C,U section steel,steel tubes

2.Surface:Hot dip galvanized

3.Size:as clients's requiremens

4.Price: reasonable price

Description

| Material | Galvanized fabricated low carbon steel |

| Zinc coating | 270-600g/ m² |

| Design snow Load | 1.5KN/m² |

| Design wind Load | 55m/s or 200km/h |

| Angle of elevation | 0°-45° |

| Production Standard | TUV, GB/5237-2008 |

| Design Standard | AS/NZS 170 |

Solar Panel Bracket Advantage

1)The Solar Panel Bracket is suitable for flat roofs of various structures or for the ground.

2)One end of the cross-beam is connected firmly with the ground structure by base bracket and hex-bolts and the another end is connected to the support leg forming a stable and strong tripod structure.

3)The connecting foot is made up of stainless steel to enhance the load bearing capacity.

- Q: How are steel structures used in the construction of parking structures?

- Parking structures commonly utilize steel structures because of their inherent strength, durability, and versatility. The use of steel offers several advantages in terms of design flexibility, construction efficiency, and long-term performance. First and foremost, steel structures provide exceptional strength and load-bearing capacity, enabling the construction of multi-level parking structures capable of accommodating a large number of vehicles. Steel possesses high tensile strength, allowing it to withstand heavy loads without deformation or failure. This makes it an ideal material for supporting the weight of numerous cars and additional loads from ramps, floors, and other structural components. Furthermore, steel structures exhibit high durability and resistance to various environmental factors. Unlike wood or concrete, steel is not susceptible to rot, decay, or insect damage. Additionally, it is fire-resistant, which is particularly crucial in parking structures, where the risk of fire is elevated due to the presence of flammable materials such as gasoline. Steel's durability ensures the longevity of the parking structure and reduces the need for frequent maintenance or repairs. Another advantage of utilizing steel in parking structure construction lies in its design versatility. Steel can be easily shaped and fabricated into a wide range of forms, enabling the creation of unique and aesthetically pleasing parking structures. This design flexibility allows architects and engineers to optimize space utilization, create open and well-ventilated structures, and incorporate features such as wide spans, cantilevers, and curved elements. Moreover, steel structures offer the potential for future expansion or modification, as they can be easily adapted to accommodate changing needs or increased parking demand. Furthermore, steel structures are prefabricated off-site, which significantly reduces construction time and minimizes disruption to the surrounding areas. Steel components are manufactured under controlled conditions, ensuring high quality and precision. Once on-site, these prefabricated elements can be swiftly and easily assembled, accelerating the overall construction process. This time efficiency is particularly advantageous in parking structure projects, where timely completion is often crucial to meet the growing demand for parking spaces. In conclusion, steel structures play a crucial role in the construction of parking structures due to their strength, durability, versatility, and construction efficiency. The ability to withstand heavy loads, resistance to environmental factors, adaptability in design, and prefabrication advantages make steel an ideal material choice for creating safe, functional, and visually appealing parking structures.

- Q: What are the advantages of using steel as a construction material for structures?

- There are several advantages to using steel as a construction material for structures. Firstly, steel is incredibly strong and durable, making it capable of withstanding heavy loads and extreme weather conditions. This strength also allows for the creation of large and open spaces, without the need for excessive support columns. Secondly, steel is a highly versatile material, allowing for flexibility in design and construction. It can be easily shaped, molded, and fabricated, enabling architects and engineers to create unique and complex structures. Additionally, steel is resistant to fire, corrosion, and pests, ensuring the longevity of the structure. Lastly, steel is a sustainable and environmentally friendly choice, as it is 100% recyclable and reduces the need for deforestation. Overall, the advantages of using steel in construction include its strength, versatility, durability, and sustainability.

- Q: How are steel structures designed for optimal natural lighting and views?

- By incorporating various techniques and features, steel structures can be designed to maximize natural lighting and views. The placement and size of windows and openings are key considerations in this regard. Architects strategically position windows on walls and roofs to take advantage of sunlight and create well-lit interior spaces. Moreover, the use of larger windows or floor-to-ceiling glass panels can further enhance the entry of natural light into the building. To optimize views, steel structures can be designed with open floor plans and expansive glass facades. These features provide uninterrupted sightlines to the surrounding environment, allowing occupants to enjoy scenic views and connect with nature. The addition of balconies or outdoor spaces further enhances the experience, providing opportunities for occupants to immerse themselves in the natural surroundings. Furthermore, the use of steel in construction offers design flexibility, allowing for creative solutions to enhance natural lighting and views. Steel's high strength-to-weight ratio enables the creation of large, open spaces with minimal columns or obstructions, maximizing the penetration of light into the building. The durability of steel also allows for the creation of large, curved or cantilevered glass elements, further enhancing the connection to the outside environment. In addition to physical design elements, sustainable design practices can contribute to optimal natural lighting and views in steel structures. Energy-efficient lighting systems and daylight sensors can be incorporated to reduce reliance on artificial lighting and make use of available sunlight. Additionally, shading devices such as exterior louvers or blinds can help control glare and heat gain while still allowing for views. Overall, designing steel structures for optimal natural lighting and views involves careful consideration of window placement, size, and design, as well as the incorporation of open floor plans, expansive glass facades, and outdoor spaces. The flexibility and strength of steel as a construction material allow for innovative design solutions that maximize the connection to the surrounding environment while providing well-lit and visually engaging interior spaces.

- Q: How do steel structures perform in terms of natural lighting?

- Steel structures typically have a high level of flexibility when it comes to incorporating natural lighting. The use of large windows, glass curtain walls, and skylights is common in steel buildings, allowing ample natural light to penetrate the interiors. Additionally, steel's strength allows for the construction of spacious and open floor plans, further enhancing the distribution of natural light throughout the structure.

- Q: How are steel columns designed?

- Steel columns are designed using a combination of engineering principles and industry standards. The design process involves several steps and considerations to ensure the columns can withstand the loads they are expected to carry. First, the design process starts with determining the load requirements. This includes considering factors such as the weight of the structure, live loads (such as people or equipment), wind loads, seismic loads, and any other applicable loads. These loads are typically specified by building codes and regulations. Once the load requirements are determined, the structural engineer calculates the maximum expected loads on the columns. This involves analyzing the structure's overall stability and distributing the loads among the columns. Different calculation methods, such as the axial load and bending moment method or the finite element analysis, may be used depending on the complexity of the structure. The next step is to select the appropriate column size and shape. This is done by considering factors such as the material properties of the steel, the column's length, and the load requirements. The engineer will typically refer to steel design manuals and tables to determine the suitable column size and shape for the given loads. After selecting the column size, the engineer will then determine the column's strength and stability. This involves calculating the column's buckling resistance, also known as its slenderness ratio. The slenderness ratio is a measure of how susceptible the column is to buckling under compressive loads. The engineer ensures that the column's slenderness ratio is within acceptable limits to prevent buckling. Additionally, the engineer will consider other factors such as connection details, fire resistance, and corrosion protection. Connection details involve designing the connections between the column and other structural members to ensure they can transfer the loads effectively. Fire resistance measures may be incorporated to ensure the steel columns can withstand high temperatures in case of a fire. Corrosion protection methods, such as coatings or galvanizing, may also be used to prevent rust and deterioration of the steel columns over time. Overall, the design of steel columns involves a thorough analysis of the loads, selection of appropriate sizes and shapes, consideration of strength and stability, and incorporation of connection details and other protective measures. This ensures that the steel columns are designed to safely and efficiently support the loads they are subjected to in a given structure.

- Q: What are the key considerations in the design of steel structures for educational facilities?

- When designing steel structures for educational facilities, there are several key considerations that need to be taken into account. These considerations include: 1. Safety: Ensuring the safety of students, teachers, and staff is of utmost importance. The design should adhere to all relevant building codes and regulations, and incorporate features such as fire-resistant materials, emergency exits, and proper ventilation. 2. Flexibility: Educational facilities often need to accommodate various activities and functions. The design should provide flexibility in terms of space utilization and adaptability to future changes in program requirements. This may involve incorporating movable partitions, modular furniture, or open floor plans. 3. Durability: Educational facilities typically have a long lifespan and need to withstand heavy use. Steel structures offer excellent durability and can resist wear and tear, as well as extreme weather conditions. Proper corrosion protection should be considered to ensure the longevity of the structure. 4. Aesthetics: The design should create a visually pleasing and inspiring environment that promotes learning. Incorporating architectural features, natural lighting, and green spaces can enhance the overall atmosphere of the educational facility. 5. Energy efficiency: As sustainability becomes increasingly important, designing energy-efficient steel structures can help reduce operational costs and minimize environmental impact. This can be achieved through effective insulation, the use of energy-efficient lighting systems, and the integration of renewable energy sources. 6. Acoustics: Educational facilities require appropriate acoustics to ensure that students can hear and understand their teachers. The design should consider soundproofing measures, such as the use of acoustic panels, to minimize noise transfer between classrooms and other spaces. 7. Accessibility: Designing for accessibility is crucial to ensure that all students, including those with disabilities, can navigate the facility independently. The design should include features such as ramps, elevators, and wide doorways to accommodate individuals with mobility challenges. 8. Technology integration: Educational facilities increasingly rely on technology for teaching and learning. The design should incorporate infrastructure to support technology integration, such as power outlets, data cabling, and wireless connectivity, to facilitate seamless use of digital tools and resources. By considering these key factors, designers can create steel structures for educational facilities that provide safe, flexible, and inspiring spaces for students, teachers, and staff.

- Q: What is the role of fireproofing in steel structures?

- The role of fireproofing in steel structures is to protect the steel from high temperatures during a fire. Fireproofing materials are applied to the steel surface to insulate it and delay the spread of heat, ensuring the structural integrity of the building and giving occupants more time to evacuate safely.

- Q: Can steel structures be designed to be flexible for future modifications?

- Indeed, it is possible to design steel structures with flexibility for future modifications. The exceptional characteristics of steel, including its strength, ductility, and versatility, make it an outstanding option for creating adaptable structures that can be effortlessly adjusted or expanded in the future. One effective approach to achieving flexibility in steel structures involves utilizing modular construction techniques. This method entails fabricating steel components off-site and assembling them on-site, allowing for simple disassembly and reconfiguration. By adopting this modular approach, future modifications can be swiftly and efficiently carried out without causing significant disruptions to the structure. Furthermore, steel structures can be designed with flexible connections that permit movement and adjustment. For instance, instead of using welded connections, bolted connections can be employed. Bolts can be easily removed and replaced to accommodate modifications, which ensures that adjustments can be made without compromising the overall integrity of the structure. Moreover, it is possible to design steel structures with sufficient load-bearing capacity to accommodate potential future modifications. By considering potential changes and additions during the initial design phase, engineers can ensure that the structure can safely support any additional loads that may be imposed in the future. To sum up, it is feasible to specifically design steel structures to be flexible for future modifications. By employing modular construction techniques, flexible connections, and considering load-bearing capacity, steel structures can readily adapt to changes and expansions. This makes them a versatile and adaptable choice for construction projects.

- Q: How are steel structures used in oil and gas facilities?

- Steel structures are extensively used in oil and gas facilities due to their durability, strength, and resistance to harsh environmental conditions. These structures play a crucial role in supporting various components and equipment within the facilities. One of the primary applications of steel structures in oil and gas facilities is for the construction of storage tanks. These tanks are used to store crude oil, refined petroleum products, and natural gas. Steel provides the necessary strength and structural integrity required to withstand the immense pressure and weight of the stored substances, ensuring their safety and preventing leakage. Steel structures are also used in the construction of offshore platforms and drilling rigs. Offshore platforms are typically located in harsh marine environments, exposed to extreme weather conditions and corrosive saltwater. Steel, especially corrosion-resistant alloys, is the ideal material choice for these structures as it offers excellent resistance to corrosion and provides the necessary strength to support drilling equipment and personnel. Moreover, steel structures are utilized for the construction of pipelines and pipe racks in oil and gas facilities. Pipelines are used to transport oil, gas, and other fluids over long distances. Steel pipes are known for their high strength-to-weight ratio, making them suitable for withstanding the internal pressure and external loads that pipelines are subjected to. In addition to these applications, steel structures are also used for the construction of support buildings, compressor stations, and various other infrastructure within oil and gas facilities. These structures provide a safe and reliable framework for equipment installation, maintenance, and operation. Overall, steel structures are essential in oil and gas facilities as they offer the necessary strength, durability, and resistance to environmental conditions required for the safe and efficient operation of these facilities.

- Q: How are steel structures used in the construction of agricultural buildings?

- Steel structures are commonly used in the construction of agricultural buildings due to their durability, strength, and cost-effectiveness. They provide the necessary support and stability required for housing livestock, storing equipment and crops, and protecting agricultural produce. Steel frames can withstand harsh weather conditions, provide ample space for large-scale farming activities, and are easily customizable to meet specific needs. Additionally, steel structures are resistant to fire, pests, and rot, making them a reliable choice for long-lasting agricultural buildings.

Send your message to us

Best Quality Solar Bracket

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- 3000 watt/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords