Structure Steel Angle Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25m.t. m.t.

- Supply Capability:

- 80000-100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Structure Steel Angle Bar

1.Invoicing on theoretical weight or actual weight as customer request

2.Standards:GB,ASTM,BS,AISI,DIN,JIS3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

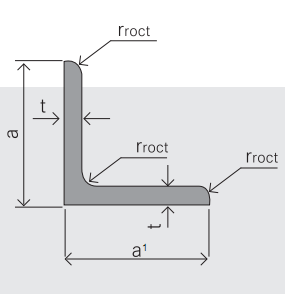

4.Sizes:

|

EQUAL ANGLES SIZES |

| ||

|

a(mm) |

a1(mm) |

thickness(mm) |

length |

|

25 |

25 |

2.5---3.0 |

6M/12M |

|

30 |

30 |

2.5---4.0 |

6M/12M |

|

38 |

38 |

2.5 |

6M/12M |

|

38 |

38 |

3.0---5.0 |

6M/12M |

|

40 |

40 |

3.0---6.0 |

6M/12M |

|

50 |

50 |

3 |

6M/12M |

|

50 |

50 |

3.7---6.0 |

6M/9M/12M |

|

60 |

60 |

5.0---6.0 |

6M/9M/12M |

|

63 |

63 |

6.0---8.0 |

6M/9M/12M |

|

65 |

65 |

5.0---8.0 |

6M/9M/12M |

|

70 |

70 |

6.0---7.0 |

6M/9M/12M |

|

75 |

75 |

5.0---10.0 |

6M/9M/12M |

|

80 |

80 |

6.0---10.0 |

6M/9M/12M |

|

90 |

90 |

6.0---10.0 |

6M/9M/12M |

|

100 |

100 |

6.0---12.0 |

6M/9M/12M |

|

120 |

120 |

8.0-12.0 |

6M/9M/12M |

|

125 |

125 |

8.0---12.0 |

6M/9M/12M |

|

130 |

130 |

9.0-12.0 |

6M/9M/12M |

|

140 |

140 |

10.0-16.0 |

6M/9M/12M |

|

150 |

150 |

10---15 |

6M/9M/12M |

|

160 |

160 |

10---16 |

6M/9M/12M |

|

180 |

180 |

12---18 |

6M/9M/12M |

|

200 |

200 |

14---20 |

6M/9M/12M |

5. Material details:

|

Alloy No |

Grade |

Element (%) |

|||||

|

C |

Mn |

S |

P |

Si |

|||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

0.12—0.20 |

0.3—0.7 |

≤0.045 |

≤0.045 |

≤0.3 |

|

|

|

|

|

|

|

|

|

|

|

Alloy No |

Grade |

Yielding strength point( Mpa) |

|||||

|

Thickness (mm) |

|||||||

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

||||

|

≥ |

|||||||

|

|

|

|

|

|

|

||

|

Q235 |

B |

235 |

225 |

215 |

205 |

||

|

Alloy No |

Grade |

Tensile strength (Mpa) |

Elongation after fracture (%) |

||||

|

Thickness (mm) |

|||||||

|

|

≤16 |

>16--40 |

>40--60 |

>60--100 |

|||

|

≥ |

|||||||

|

|

|

|

|

|

|

|

|

|

Q235 |

B |

375--500 |

26 |

25 |

24 |

23 |

|

Usage & Applications of Structure Steel Angle Bar

According to the needs of different structures, Angle can compose to different force support component, and also can be the connections between components. It is widely used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packaging & Delivery of Structure Steel Angle Bar

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

- Q: Can steel angles be used in residential construction?

- Yes, steel angles can be used in residential construction. Steel angles are versatile structural elements that are commonly used in various construction applications, including residential buildings. They are often used for framing, reinforcing, and providing structural support in walls, roofs, and floors. Steel angles are preferred in residential construction due to their strength, durability, and ability to withstand heavy loads. They can be easily welded, bolted, or screwed into place, making them suitable for a wide range of construction projects. Additionally, steel angles can be galvanized or coated to enhance their resistance to corrosion, ensuring their longevity. Overall, steel angles are a reliable and cost-effective choice for residential construction.

- Q: What are the different grades of steel used for angles?

- The different grades of steel used for angles can vary depending on the specific application and requirements. However, some common grades of steel used for angles include A36, A572, and A588. A36 steel is a low carbon steel that is commonly used in structural applications. It has good weldability and machinability, making it a versatile choice for angles. A36 steel angles are often used in construction, manufacturing, and general fabrication projects. A572 steel is a high-strength, low-alloy structural steel that is commonly used in structural applications such as bridges, buildings, and construction equipment. It offers excellent strength, weldability, and formability, making it suitable for angles that require higher strength and durability. A588 steel, also known as weathering steel, is a high-strength, low-alloy steel that is designed to have enhanced atmospheric corrosion resistance. This makes it suitable for outdoor applications where exposure to the elements can cause corrosion. A588 steel angles are often used in outdoor structures such as bridges, buildings, and sculptures. These are just a few examples of the different grades of steel that can be used for angles. The choice of grade will depend on factors such as the specific application, required strength, corrosion resistance, and cost. It is important to consult with a professional or reference industry standards to determine the most suitable grade of steel for a particular angle application.

- Q: What are the common grades of steel used for angles?

- The common grades of steel used for angles vary depending on the specific application and requirements. However, some of the most commonly used grades of steel for angles include A36, A572-50, and A588. A36 is a low carbon steel that is commonly used in construction and structural applications due to its strength and versatility. A572-50 is a high-strength, low-alloy steel that is often used in structural applications and has excellent weldability and formability. A588 is a high-strength, low-alloy steel that is primarily used in outdoor applications such as bridges and buildings, as it has excellent corrosion resistance. These grades of steel offer different characteristics and properties, allowing for various applications and ensuring the angles meet the specific project requirements.

- Q: Can steel angles be used for framing purposes?

- Yes, steel angles can be used for framing purposes. Steel angles are commonly used in construction and engineering to provide structural support and stability. They are often used to create frames for buildings, bridges, and other structures. Steel angles can be easily welded or bolted together to form a strong and rigid frame. They are versatile and can be used in various framing applications, such as supporting walls, beams, and roofs. Additionally, steel angles are durable and have high strength-to-weight ratio, making them ideal for framing purposes.

- Q: What is the typical corrosion rate of steel angles?

- The typical corrosion rate of steel angles can vary depending on several factors such as the environmental conditions, the type of steel used, and the presence of any protective coatings. In general, steel angles are susceptible to corrosion due to their iron content. However, with proper maintenance and the application of protective measures, the corrosion rate can be significantly reduced. In mild atmospheres or indoor environments with low humidity and minimal exposure to corrosive agents, the corrosion rate of steel angles can be relatively low, typically ranging from 0.1 to 0.5 mils per year (1 mil is equivalent to 0.001 inches). This slow corrosion rate allows steel angles to maintain their structural integrity over an extended period. However, in more aggressive environments such as coastal areas with high salt content in the air or industrial settings with exposure to chemicals, the corrosion rate can be significantly higher. In these cases, the corrosion rate of steel angles can range from 0.5 to 2 mils per year or even higher. In such environments, it is crucial to implement measures like regular inspection, cleaning, and the application of protective coatings to mitigate the corrosion rate and prolong the lifespan of the steel angles. It is important to note that these corrosion rates are typical estimates, and actual rates may vary based on the specific conditions and factors mentioned earlier. Consulting with a corrosion engineer or utilizing corrosion rate data specific to the environment and steel type can provide a more accurate estimation of the typical corrosion rate for steel angles in a particular situation.

- Q: How do steel angles perform in high-temperature environments?

- Steel angles perform well in high-temperature environments due to their inherent properties. Steel is known for its high melting point and thermal conductivity, which allows it to withstand elevated temperatures without significant structural degradation. In high-temperature environments, steel angles maintain their strength and stability, making them suitable for various applications. One reason for the excellent performance of steel angles in high-temperature environments is their ability to retain their structural integrity. Steel has a high melting point, typically ranging from 1300 to 1500 degrees Celsius, depending on the specific grade. This property ensures that steel angles can withstand and maintain their shape even in extreme heat conditions. Furthermore, steel has a low coefficient of thermal expansion, meaning it expands and contracts minimally when exposed to temperature changes. This characteristic is vital in high-temperature environments as it reduces the risk of warping or distortion of steel angles. The dimensional stability of steel angles enables them to withstand thermal cycling without compromising their structural strength. Additionally, steel exhibits excellent thermal conductivity, allowing it to effectively dissipate heat. This property prevents the accumulation of excessive heat in steel angles, reducing the risk of thermal stress or failure. Steel angles efficiently transfer heat away from critical components, increasing their durability and longevity in high-temperature environments. Moreover, steel angles are often coated or treated with heat-resistant materials to enhance their performance in extreme heat conditions. These coatings provide an additional layer of protection against oxidation, corrosion, and thermal degradation, further improving the resilience of steel angles in high-temperature environments. In conclusion, steel angles are well-suited for use in high-temperature environments due to their high melting point, low thermal expansion, excellent thermal conductivity, and the possibility of additional heat-resistant coatings. Their ability to maintain structural integrity, dimensional stability, and heat dissipation make them a reliable choice for various applications where exposure to elevated temperatures is a concern.

- Q: What is the bending capacity of a steel angle?

- The ability of a steel angle to withstand bending or flexing without breaking or deforming excessively is known as its bending capacity. This capacity reflects the angle's structural strength and is typically influenced by factors such as the angle's dimensions, thickness, type of steel, and presence of any additional reinforcements or supports. To determine the bending capacity, it is common to express it as the maximum load or stress that the angle can endure before it permanently deforms at its yield point. The bending capacity of a steel angle can vary significantly based on these factors, and it is of utmost importance to consider this capacity during the design and construction of structures that incorporate steel angles to ensure their structural integrity and safety.

- Q: Are steel angles fire-resistant?

- Yes, steel angles are fire-resistant to a certain extent. Steel is a non-combustible material, meaning it does not burn or contribute fuel to a fire. It has a high melting point, usually around 1370°C (2500°F), which allows it to maintain its structural integrity even under high temperatures. However, it is important to note that while steel itself is fire-resistant, the fire resistance of a structure or component depends on various factors such as the design, size, and configuration of the steel angles, as well as the fire protection measures implemented. Fire protection methods like fire-resistant coatings, fireproofing materials, or fire-resistant insulation can be applied to steel angles to enhance their fire resistance. These additional fire protection measures can provide a certain level of insulation, delaying the transfer of heat to the steel and extending the time it takes for the steel to reach its critical temperature. This allows occupants more time to evacuate the building and firefighters more time to control the fire. In summary, steel angles are inherently fire-resistant due to the properties of steel, but their fire resistance can be further enhanced by implementing appropriate fire protection measures.

- Q: What is the typical thickness tolerance for steel angles?

- The thickness tolerance for steel angles may vary based on manufacturing standards and requirements. Typically, steel angles have a thickness tolerance ranging from +/- 0.005 to 0.010 inches (0.13 to 0.25 mm). Nevertheless, it is crucial to consider that the tolerance can be affected by the size and dimensions of the angle. Larger and thicker steel angles may have slightly more lenient tolerances compared to smaller and thinner angles. To determine the precise thickness tolerance for a specific steel angle, it is advisable to refer to the appropriate industry standards or specifications.

- Q: How do steel angles perform under impact or dynamic loading conditions?

- Steel angles are known for their exceptional strength and durability, making them highly capable of withstanding impact or dynamic loading conditions. When subjected to sudden forces or dynamic loads, steel angles exhibit resistance to deformation, bending, and fracture, thanks to their high tensile and yield strengths. The shape of steel angles, with their L-shaped cross-section, adds to their structural integrity and ability to resist impact. The flanges of the angle distribute the load evenly, effectively transferring the forces to the supporting structure. This design feature allows steel angles to efficiently absorb and distribute the impact energy, reducing the risk of failure or structural damage. Steel angles also possess excellent fatigue resistance, enabling them to endure repeated or cyclic loading without weakening or experiencing fatigue failure. This is crucial in applications where dynamic or fluctuating loads are prevalent, such as bridges, cranes, machinery, and various structural components subject to vibrations or dynamic forces. Moreover, steel angles can be further enhanced through various techniques, such as heat treatment or alloying, to improve their impact resistance and toughness. These methods can increase the hardness and strength of the angle, making it even more capable of withstanding severe impact or dynamic loading conditions. Overall, steel angles are a reliable choice for applications involving impact or dynamic loading conditions. Their combination of high strength, structural integrity, and fatigue resistance allows them to perform exceptionally well under such circumstances, ensuring the safety and longevity of the structures they are incorporated into.

1. Manufacturer Overview

| Location | Tangshan, China |

| Year Established | 1996 |

| Annual Output Value | Above US$ 300 Million |

| Main Markets | Middle East; Korea; Southeast Aisa |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 70% - 80% |

| No.of Employees in Trade Department | 21-30 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 900,000 square meters |

| No. of Production Lines | 3 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Structure Steel Angle Bar

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25m.t. m.t.

- Supply Capability:

- 80000-100000MTS/YEAR m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords