Vertical Split Case Centrifugal Pumps Double Suction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

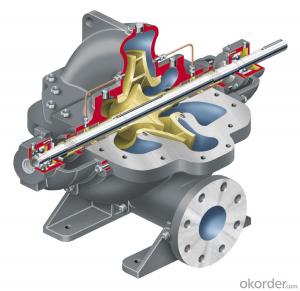

Vertical Split Case Centrifugal Pumps Double Suction

Application

Single Stage Double Suction Split Case Pump is used for conveying water or the physical and chemical properties similar to water and other liquids suitable for factories, mines, urban water supply, power stations, agricultural irrigation and water conservancy.

Characteristic

Compact structure,beautiful outline,stable operation,low noise;

Both inlet and outlet of this pump are placed under the axial line,so it is unnecessary to remove the inlet and outlet pipeline and motor;

The shaft seal of water pump has fine mechanical seal and soft stuffing seal,which can be selected according to different condition by user;

The impeller is static-balance calibrated,fixed on the shaft with round nut,and its axial position can be adjustedvia the round nut;

The pump is direct drived by motor via resilient coupling,it can be drived by internal combustion engine if it is necessary.

Technical Data

| Capacity | 50-20000m3/h |

| Head | 10-230m |

| Speed | 2900/1450/980/740/580/3500/1750/1180/890/710rpm |

Material

Casing: Cast iron/ ductile cast iron/cast steel/stainless steel/duplex stainless steel

Impeller: Cast iron/ ductile cast iron/brone/stainless steel/duplex stainless steel

Shaft:C-steel/stainless steel

The rotation direction

Viewed from motor, the direction of the pump is anti-clockwise,that is the suction in the left, the discharge in the right.

The rotating direction of the type pump is clockwise, that is the suction in the right, the discharge in the left.

Also can move the driver to another edge according to the user’s requires. Then, the rotating direction, the suction and discharge direction is in the opposite as the described above.

Photo

- Q: how much is it to replace timing belt and water pump on a Chrysler voyager 2002?????

- Timing belt can be be anywhere from $200 to $400,but make sure a pro does it beaches if it's put on wrong and off time it can mess up your engine and that would be in the thous..this happened to me.. Water pump idk

- Q: Having a hard time taking out the water pump on my 2004 Grand Am. it's been leaking anti-freeze for some time and finally had the time to fix it. Didn't know it will be so difficult to take out. So hopefully it won't be so difficult to put back up.

- You did not say if you have a 4 cylinder or a 6 cylinder. The 6 is really easy so I will assume you have a 4.If equipped with an automatic transmission, remove the exhaust manifold. Refer to Exhaust Manifold Removal in Engine Mechanical - 2.2L (L61). Drain the cooling system. Refer to Cooling System Draining and Filling . Raise and suitably support the vehicle. Refer to Lifting and Jacking the Vehicle in General Information. Remove the right front tire and wheel. Refer to Tire and Wheel Removal and Installation in Tires and Wheels. Remove the front fender liner. Refer to Front Fender Liner Replacement in Body Front End. Remove the access plate on the water pump sprocket from the timing cover. Install J 43651 to the water pump sprocket. Use the access plate bolts to secure J 43651 to the engine front cover. Remove the bolts that secure the sprocket to the water pump. Remove the bolt (1) that secures the engine block to the water pump. Remove the bolt (2) that secures the engine front cover to the water pump. Remove the feed pipe that joins the thermostat housing to the water pump. Remove the 2 bolts that secure the water pump to the engine block. Remove the water pump.

- Q: I have a submersible pump outdoors for the water to my house. Indoors is a holding tank and pressure gauge. It seems the pressure gauge keeps slowly declining down to 20. Then when the toilet is flushed, the gauge kicks on and climbs to 50. Then left alone for a while the gauge again declines to 20. Do I have a leak somewhere? If so , where? Does the ballast inside the holding tank need to be pressurized? If so, how where? I seem to remember years ago, my husband did something with a bicycle tire air pump. Makes sense? Thanks

- If it's going down while nobody is using water then the check valve or foot valve is leaking through when the pump is off. It should pump it to a determined PSI then shut off. I suppose there could be a leak somewhere in the line, but I suspect the check valve. It's pretty common. ....the ballast does need to be pressurized but I doubt that's your problem. If that was bad you would have severe water hammer.

- Q: I'm not too familiar with computerized cars, just wondering if the water pump going out would cause the car not to start?

- No. Do you have power? Battery, alternator. Does it crank? Starter, solenoid, wiring, ignition. If all the above is ok, then what's left is air, fuel, and fire. You need all these to have a running vehicle. Fuel system-pump, filter, pressure regolator... Air-filter, maf sensor... Fire- plugs, wires, cap/rotor...

- Q: My water pump is starting to leak. The shops are quoting $250- $300 to replace but I can buy a water pump at the auto parts store and install myself for less than $100 but I don't know what all is involved with this repair or if I should try (my only experience with car repair up to now is recently replacing the alternator). If anyone has done this please let me know what you think. thanks

- It's a rear wheel drive car with the water pump mounted on the front of the engine toward the radiator. So if you go to the library any read the chiltons or motors manual procedures on how to replace the water pump, you probably have to remove the radiator fan blade assembly to get at the water pump. Some fan belts will also have to be removed. You can end up doing the job twice if the new water pump gasket doesn't seal properly due to antifreeze leaking out of the engine block while your installing the new gasket and sealer. Park the car with the engine facing up a hill to prevent that. I'd have it done at a shop. It's worth paying a shop unless you really want to get into major repairs.

- Q: I will be replacing my timing belt soon. The dealer is suggesting that I also replace the water pump. Is that really necessary? When do water pumps normally go out?

- The labor involved in replacing a timing belt will normally cover the installation of a water pump as well. The reason the dealer is recommending the water pump replacement at this time is that the labor involved in changing the timing belt makes it much more cost effective for you to do it at this time. Even though your water pump is working great right now, if you need to replace it in the future, the labor cost will be enormous and close to the cost of replacing your timing belt alone.

- Q: My car is over heating.the hose that goes to the thermostat is swollen.i wanted to open the radiator to release the pressure but it was too hot ,and too much pressure. is this a sign that the water pump is good?

- First let me say the GOOD LORD was watching over you. You NEVER NEVER NEVER open a radiator cap when it is hot. Had a friend do that and he now has scars on his chest where the water sculled him. Yes it is working. What you need to do is change the thermostat. But please wait until the engine is cool to the touch.

- Q: Why can't vertical water pump use spring shock absorber?

- Vertical pump power is small, the weight is limited, the pipeline vibration is limited, the general rubber shock absorber will be enough. It's no use. I'm sure you can't use the spring shock absorber.General construction, 7,5KW below is rubber shock absorber, above is spring shock absorber

- Q: We have a 92 cadillac deville, my husband can replace the water pump he justs need to know if you have to jack the motor a little. Please help before our car blows up!!

- It okorder /

- Q: Is a 3000 watt generator sufficient to power a 3/4 horsepower water pump?My house has a 3/4 horsepower pump that it uses to pump water from the well to the house. I want to purchase a generator that will be sufficient to power this pump in a power outage. Is 3000 Watts sufficient?

- Danny and GTB give a good answer, I just add some: As a rule of thumb, 1 horsepower (HP or hp) is equal to 750 watts, and a motorized electric equipment at start up will suck electricity power about twice as much as its specification. Is you pump equipped with a three phase or a single phase electric motor? You have to suit it with the generator. As for the generator, if possible you choose a generator with big flywheel, with slower RPM -rotations per minutes- than a generator with high RPM, because a water pump will frequently on and off according to the usage. This could cause the generator to wave down and up accordingly. Or a generator equipped with an electronic governor that will react fast enough to the frequent on and off load of the water pump. Hope the best and God bless you and good luck day by day!!

Send your message to us

Vertical Split Case Centrifugal Pumps Double Suction

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 unit

- Supply Capability:

- 1000 unit/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords