UV Coating Wood Grain Decorative Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Cement Boards) Description

1. High strength and light weight

2. Fireproof and waterproof

3. 100% free of asbestos

4. Energy saving.

2,Main Features of the (Cement Boards)

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives. It's a kind of high-tech product which formed through accurate dosing by computer program, hatschek craft and compressed by 14000tons hydraulic machine and autoclaved under high temperature and pressure.

It's 100% free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance like high strength, large size, light weight, fire and water proofing, green and environmental friendly, high efficient and energy-saving. Therefore, this kind of new material is vigorously developed and recommended by the country.

Thickness: 3.5-30mm

Standard size: 1220*2440mm or 1200*2400mm

Note: other specification is available

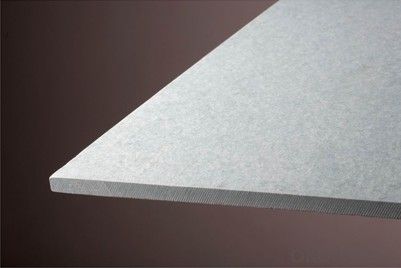

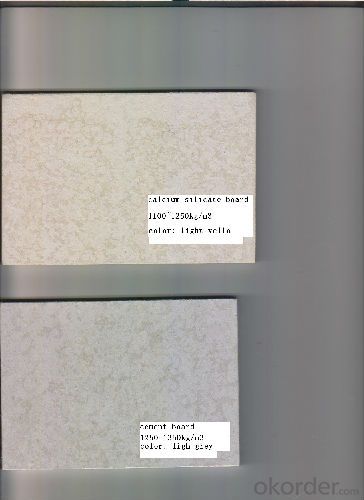

3,(Cement Boards) Images

4,(Cement Boards) Specification

Index | Moderate compressed | ||

Density(g/cm3) | 1.44 | ||

Water absorption (%) | 28 | ||

Wet expansion (%) | 0.17 | ||

Water penetration | No water drop on the board surface after 24hours | ||

Modulus of Rupture | Air dried condition | 14 | |

Saturated condition | 10 | ||

Frost resistant | No delamination and crack after 25cycles under freezing and thawing | ||

Index | High density | ||

Density(g/cm3) | 1.64 | ||

Water absorption (%) | 17.8 | ||

Wet expansion (%) | 0.15 | ||

Water penetration | Back side without water drop after 24 hours | ||

Modulus of Rupture | Air dried condition | 20.1 | |

Saturated condition | 15.0 | ||

Frost resistant | No layers and no cracks after 25 cycles under freezing and thawing | ||

Index | Middle density | ||

Incombustibility | Incombustible Class A1 | ||

Water penetration | Back side without water drop after 24 hrs | ||

Modulus of rupture | Air dried condition | 15 | |

Saturated condition | 12 | ||

5,FAQ of (Cement Boards)

1. Interior and exterior wall; Furred ceiling

2. Insulation materials, floor; Road barrier

3. Sound-adsorbing wall & suspended ceiling

- Q: Why does noise do not mean sound absorption? How to use good sound insulation, sound absorption material to handle the hall? Ask the master enlighten me!

- Second, to prevent the sound of vibration transmission: This plate requires a higher density of the unit surface, that is, the higher the density of the unit surface noise better, which is why the thick wall than the thin wall sound insulation better reason. Usually have fiber cement board and other products. Stone also has a good sound insulation, medium and thick steel plate has a good sound insulation effect.

- Q: Has anybody made a claim for and been paid for the cement board siding class action lawsuit?

- Dont okorder has some good examples of past class action lawsuits and for a really good read, read Grisham's the king of Torts. Right now I am actually a part of a class to recover FOREX fees on my credit card. I have lost probably a few hundred dollars i expect to be granted $5! Wahoo!

- Q: or add visquine on top of the plywood and then put on the backer board

- That is the proper way to do it. You need the thin set to act as a filler so there are no voids at all between the ply and the cement board. 1/4x1/4 notched trowel is the required trowel. This is according to tile installation ( both ATC and TCA tile guide line codes) and the cement board manufactures way to do it. Any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: also how much is luber per board foot cost.

- One bag of Cement is 195 pesos. ($4). Cocoa Lumber is P50 per board foot.

- Q: some say lay 15 pound paper what gives?

- It's a cushion -bed for the cement board. Less chance of it cracking if cushioned.

- Q: I need to fix a loom board cause one of the pegs broke we don't have superglue but we have vinyl cement can I use that?

- whoa down kimosabe glue of anykind will fail any and all trust me take a pair of pliers and break the peg off flush the proper fix is to drill and set a new peg and wood glue would be your best choice a faster option is to use a nail in place of the peg not the same diameter i know use masking tape to increase the diameter of the nail fast ez no glue drying time

- Q: I have a porch that is currently covered in green turf carpet. I'd like to rip off the turf, clean the cement and mortar on small stone pavers. I will be placing the stones not only on the top, but the sides, and tread and risers of the stairs as well. Can I mortar directly onto the cement or should I use backer-board? If a backer-board is needed, how do I connect the backer-board onto the concrete? Will I need special screws?

- You do not need backer board since it is concrete. Just clean the concrete good with a garage floor cleaner and rinse and let dry. Try to do this when the hot sun is not beating down on the concrete. Use thinset mortar and a notched trowel to put it on. Figure out what kind of pattern you are goint to lay-maybe just regular common end to end? Put thinset on an area about 3' x 3' and push your pavers down into it and wiggle them just a little - after you have set some take a 4' level and a rubber mallet - tap on top of level until all the pavers are setting about the same, then move level to next row repeat. If you have some thinset on and you want to stop or take a break - just scrape it of with putty knife and put back into your mortar bucket. Cover mortar bucket with lid or damp cloth when your not getting into it. Cut pavers with a 4-1/2 grinder with a diamond blade. Watch your bottom step- you may need to cut pavers on this step down or this step may be higher than all the others.

- Q: do i have to use cement board under tile on a shower wall?

- Yes, unless you want to replace the tiles again. Anything else will be subject to moisture and flexing. Those conditions will cause the tiles to fall off.

- Q: I'm looking to install siding on my home and just looking for answers to the obvious concerns....... maintenance, longevity, and energy efficiency>

- From an evergy efficency standpoint, neither has enough R value to even enter into the decision. With vinyl siding, you can add a rigid foam insulation behind the siding prior to installation that will increase the R value and some high end vinly comes with a foam insulation already laminated to the back. Hardi Board makes a pre-painted siding that has a 15 year warranty on the paint job. It doesn't ding, crack, or blow off in a strong wind. Plus, it looks like authentic wood siding (but much less expensive) However, you will pay substantially more than vinyl siding. For most people it comes down to price. When given all the facts, fiber cement is by far the superior product but if its not in your budget then vinyl siding is a respectable alternative.

- Q: how can you tell the difference between asbestos and cement board?

- Cement Board Asbestos

Send your message to us

UV Coating Wood Grain Decorative Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords