Fiber Cement Board Panels Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1,Structure of (Cement Boards) Description

fiber cement board

-Factory price

-SGS,CE

-Non-asbestos, light weight, high density

-Waterproof, fireresistant, anti-bendingfiber cement board panels sheet for exterior cladding wall construction building material

2,Main Features of the (Cement Boards)

Fire-proof Rate: Class-A incombustible GB8624-1997

Incombustibility (min):240 minutes(GB/T9978-1999)

Density:1100~1500g/cm3

Water content ratio: ≤30%

Swelling ratio:≤0.4%

Anti-bending strength:≥16MPa

Frost Resistance: no cracking after 25 cycles of freezing and thawing(GB/T7019-1997)

Radioactivity: standard of BG6566-2001 Class-A Decoration materials.

Size & Loading Quantity of fiber cement board:

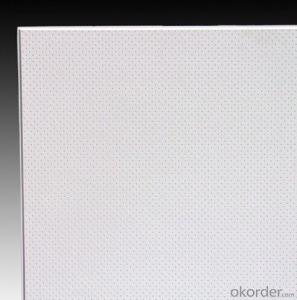

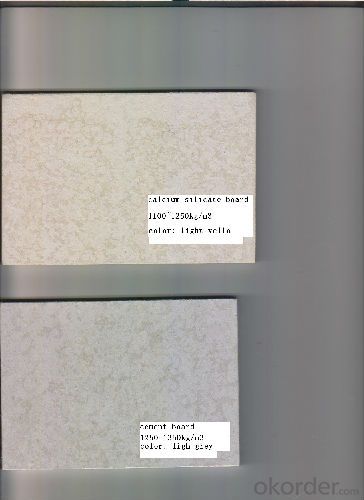

3,(Cement Boards) Images

4,(Cement Boards) Specification

| Thickness (mm) | Length x width (mm) | PCS/ 20GP | Surface |

| 5mm | 1200mm x 2400mm 1220mm x 2440mm | 1050 PCS | Single, double surface Sanding or tapered |

| 6mm | 1200mm x 2400mm 1220mm x 2440mm | 880 PCS | Single, double surface Sanding or tapered |

| 8mm | 1200mm x 2400mm 1220mm x 2440mm | 656 PCS | Single, double surface Sanding or tapered |

| 9mm | 1200mm x 2400mm 1220mm x 2440mm | 588 PCS | Single, double surface Sanding or tapered |

| 10mm | 1200mm x 2400mm 1220mm x 2440mm | 520 PCS | Single, double surface Sanding or tapered |

| 12mm | 1200mm x 2400mm 1220mm x 2440mm | 442 PCS | Single, double surface Sanding or tapered |

| 15mm | 1200mm x 2400mm 1220mm x 2440mm | 346 PCS | Single, double surface Sanding or tapered |

| 18mm | 1200mm x 2400mm 1220mm x 2440mm | 294 PCS | Single, double surface Sanding or tapered |

| 20mm | 1200mm x 2400mm 1220mm x 2440mm | 260 PCS | Single, double surface Sanding or tapered |

5,FAQ of (Cement Boards)

Customized sizes and thickness are also produced.

Reccommend application of fiber cement board

Partition board , suspended ceilings,exterior wall cladding, paneling ,light weight grouting panel, interior dry wall decoration board, interior wall after painting and coating.

3.5-6mm : for interior ceiling

7-20mm : for drywall partition

- Q: Cement concrete pavement thickness of the number of appropriate?

- Most of the concrete pavement made of equal thickness section, thick 20 to 25 cm.

- Q: I am building a balcony. We were going to do tile, but may do a waterproof product instead. There is currently cement board glued (not screwed) to the torch down. Screws were not used because we don't want to have an area where water can seep in. Now I am worried about the glue failing and the cement boards lifting (same issue with tile come to think of it). Is the glue enough to hold down the cement board so I won't have problems in the future?

- If your to do ceramic tile then yes you need to screw and glue: it down. This glue isnt really to hold it down like most people think, its part of the support base for ceramic. You still must nail or screw it down in the require amount in the field ( 8 on center and seams a minimum of 4/6 apart.) If you live in a climate that gets cold enough for freezing , the I recommend you don t use a ceramic or porcelain tile ( frost proof or not) Using a cement board isn t the proper way to do an exposed balcony , even to rain. You need to treat it as a shower flooring and use a drain , liner , and s special cement to form a slight slope to the drain from all direction. It is possible ( Ive never done it yet) to properly do a cement board and water proof the top . The water proofing will have to be flashed up the sides to make a water proof flooring and still incorporate a draining system. If you have any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Can cement board be tiled?

- No need, Directly on the cement board tiling, If the cement board too light can be polished nap

- Q: How to open the cement board

- We are the first to draw a good position with a hand drill drill holes in the use of curved saws [hand saws] slowly saw the round hole out, that slot machine can also be used;

- Q: I have a small bathroom approximately 4'x8' and I laid down and screwed in cement backer board. However, in my attention to detail I neglected to put down thin-set mortar underneath prior to screwing and taping down the board. I tried to pull the cement board up but I cant get under the tape that I mortared down to get to the screws. Am I in trouble here or can I go ahead and skip that and continue to tile? Please help...

- I have not seen thinset used under the cement board unless the surface had high/low spots. As long as the area is flat, continue on.

- Q: Can the cement board be affixed to the woodworking board?

- Why do not art glass cut off it? In the back of the cabinet for the glass, the cost will not be much higher, and beautiful. If the tile above the tile, it is necessary to use glass glue, damp after the board may be deformed, affecting the appearance of the tile is more likely to fall off.

- Q: How does the cement pressure plate hang on the old wall with paint?

- I do not know what your old wall is now, if you can meet the three points, you can directly use the glue on the line: First, flat, two, clean, three: solid (this is very important), our company specializing in cement board Sales, this is also more proficient in this,

- Q: Looking to connect a piece of plywood between two boards to hang a banner

- I am okay with the 5 gallons of concrete, that will weigh close to 100 lbs per bucket. I would use 1.5 - 2 inch pvc pipe, not 2x4's. That will give you better flex. For the banner, it is up so high that the wind loading and leverage will be a problem if you tie all four corners. So just connect the two poles with a rope at the top and hang the sign from the rope. This way in a wind, the bottom will just blow free. If you must tie the banner at 4 corners, you need a flatter container of concrete. An old tire, filled with concrete, will work for this purpose. Put a piece of plywood across the tire so it will hold the concrete. That's what we used for tether ball.

- Q: Its a baffle over an old fireplace where a gas heater has been installed. A cement based repair was hopeless, builders glue lasted a while but eventually busted when heater used on high for lengthy period. Crack getting bigger so need to get it fixed before a re-installation becomes necessary. Thanks.

- you could use a fire cement, that they use to seal coal and wood stoves,it comes already mixed,so you just spread it and level it,and it dries in no time at all,and it is designed for high temperatures

- Q: Just put cement type 1 portland,over hardie board about 3/8 of an in. how long do i have to wait to stain it?

- i would give it a week, it should set pretty quick...

Send your message to us

Fiber Cement Board Panels Sheet

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords