Fire Resistant Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

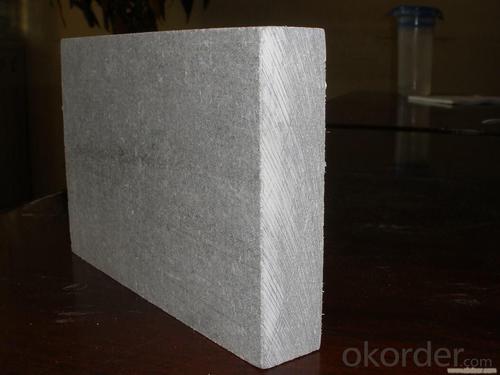

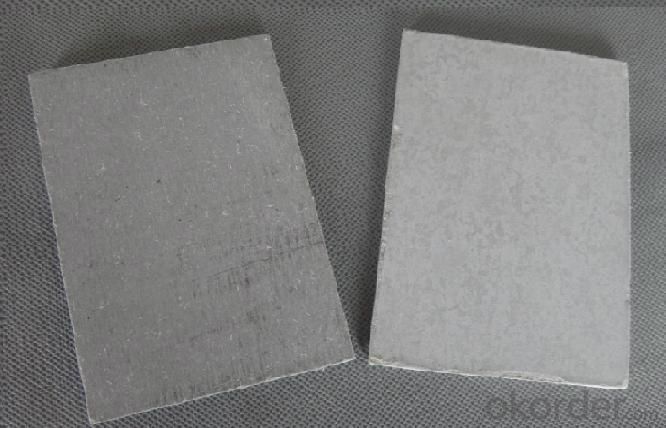

on-asbestos Fiber Reinforced Calcium Silicate Board

Refractory temperature:1770-2000°C

Grade: A1 incombustible

Thermal conductivity: 0.03

Material: cellulose fiber

Shape: rectangle

Form: flat sheet

Size: 2440*1220*(4-40)

Product Advantages:

Product categories: fire prevention board

Flexure strength: 14

Operating temperature: normal temperature

Introduction

Non-asbestos fiber reinforced calcium silicate board is low shrinkage fiber cement preesure board which uses cement, quartz, lime, fly ash, cellulose fiber, inorganic fiber and other materials as main material, manufactured by advanced technology and techniques to form green sheet, and then pressed by thousands tons pressure, cured by high temperature and high pressure steam and other special treatment.

Product feature

Fire prevention, waterproof, high strength, corrosion resistance, heat insulation, sound insulation, durable, long service life, safe and convenient construction.

Main applications

Non-asbestos fiber reinforced calcium silicate boards are mainly used in all kinds of internal and external wall: insulation wall, sound absorption wall, casting wall, compound wall, overclapping wall, scales wall, subway(underground) water gushing wall, thermal insulation wall, exterior thermal insulation panels.

For ceiling: sound absorbing roof, sound insulation roof, large flat, T-top roof and so on.

For decorative panels: (surface coating, paste decoration) furniture barrier panels, acoustic enclosures, electrical insulation board, industrial board, ventilation pipe plate, free open type templates.

Main Product Features:

thermal conductivity:0.048w/m.k

model size 600*300*50mm

working temp 1000C

linear shrinkage 2%(1000C 6H)

100% asbestos free

Advantages of Calcium Silicate Board:

Characterized by exceptional heat resistance,outstanding thermal insulation,very low bulk density,high specific strength,excellent durability and flexible construction,high temperature calcium silicate insulating slabs can be widely used as energy-saving materials for almost all types of industrial furnaces.

Properties of Insulation Calcium Silicate Board:

Product Specifications:

| Items | Unit | HCS-17 |

| Bulk Density | kg/m3 | 220(±10%) |

| Flexural Strength | Mpa | ≥0.30 |

| Temp.Limit | °c | 1000 |

| Linear Shrinkage | % | ≤1.5(1000°c 3hrs) |

| Thermal Cond. | W/m.k | ≤0.048+0.00011t |

Images:

- Q: Decorative fire board environmental protection? How to choose to buy environmentally friendly decorative fire board?

- Application of special coating process, in the sheet surface coating high-performance environmentally friendly coatings, the formation of high-quality fire environmental decorative panels. Known as green, low carbon, energy saving, environmental protection of the new decorative plate, instead of the traditional wood sheet, marble, tiles and other decorative materials, and the surface wear easy to clean, impact resistance, color stability, moisture and weather resistance.

- Q: I removed old tile from my bathroom walls as well as the old vinyl flooring. Underneath the vinyl was cement backerboard, which is good. But all around the outer edges where the wall tile used to be, is a 1 inch gap where the floor board are showing. How do I get this gap filled? Do I need to rip up the old cement backerboard and start over? Can I cut small strips of new backerboard to slip in the crevice? Is there a compound I can fill the gap with? Any help out there?

- Fill it with thin-set. There won't be any pressure applied along the wall. Fill with thin-set and wait 24 hours to dry before installing tile. Just make sure to smooth it out and it's level with rest of the backer-board floor.

- Q: I am building a balcony. We were going to do tile, but may do a waterproof product instead. There is currently cement board glued (not screwed) to the torch down. Screws were not used because we don't want to have an area where water can seep in. Now I am worried about the glue failing and the cement boards lifting (same issue with tile come to think of it). Is the glue enough to hold down the cement board so I won't have problems in the future?

- If your to do ceramic tile then yes you need to screw and glue: it down. This glue isnt really to hold it down like most people think, its part of the support base for ceramic. You still must nail or screw it down in the require amount in the field ( 8 on center and seams a minimum of 4/6 apart.) If you live in a climate that gets cold enough for freezing , the I recommend you don t use a ceramic or porcelain tile ( frost proof or not) Using a cement board isn t the proper way to do an exposed balcony , even to rain. You need to treat it as a shower flooring and use a drain , liner , and s special cement to form a slight slope to the drain from all direction. It is possible ( Ive never done it yet) to properly do a cement board and water proof the top . The water proofing will have to be flashed up the sides to make a water proof flooring and still incorporate a draining system. If you have any questions you can e mail me through my avatar and check my qualifications there. GL

- Q: Can cement board be tiled?

- Kitchen flue is made of cement board if the wall is not hard to use the red brick and then posted again

- Q: Has anybody made a claim for and been paid for the cement board siding class action lawsuit?

- Dont okorder has some good examples of past class action lawsuits and for a really good read, read Grisham's the king of Torts. Right now I am actually a part of a class to recover FOREX fees on my credit card. I have lost probably a few hundred dollars i expect to be granted $5! Wahoo!

- Q: Composite foam cement board fire board grade and fire resistance limit?

- ire rating B: B-class refractory grade is a flame retardant material, the general high-end public places are used in the use of this material decoration.

- Q: I have a bare concrete/cement floor. After I installed Travertine on one section, it is almost 1/2 inch above the floor. Now, I want to continue to install the other section of the floor with laminate wood, but the floor is too low compared to the travertine floor. The question are: Can I put down a particle board over the concrete/cement floor, then a foam pad (moisture barrier), then laminate wood?Will the particle board absorb water then swell up?Or do I need to put down the moisture barrier foam first, then particle, then laminate wood?If I am not using the particle board, the laminate wood floor will be about 1/8 lower than the travertine floor. is it ok?

- Do NOT use particle board. There is no reason, as the laminate can be laid over the concrete with the proper padding. The particle board may swell and cause you issues down the road. Check the instructions on the flooring. Some require a plastic vapor barrier under them, while others only need the padding. 1/8 is not a big deal. The transition strip will bridge the difference. Be sure to check for peaks and valleys in the concrete, and fill in low spots. This will prevent the tongues on the planks from snapping off, leaving gaps in the floor. Allow the laminate to acclimate to the basement for a week or so before installing. Hope this helps. EDIT: You don't need anything under the flooring except vapor barrier or padding. They are designed to be able to be installed on a concrete base. Good luck.

- Q: is there an easier way than just hammering to break it up until we ache? By old school we mean the house was built in the 50's and there is some type of chicken wire material in it.

- hammer and chisel all the tile off first then use a saws-all to cut the wall board into smaller pieces (you need the right blade for the saws-all)

- Q: almost finished with tiling on cement board wall. ran into problem with corner applying bull nose piece.?

- I agree, whats the problem? I have a guess what it could be but you actually need to tell us. Any questions you can e mail me through my avatar and check my qualifications there. GL

Send your message to us

Fire Resistant Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords