Colored Ceramic Fiber Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Quick Details

| Application: | Liners Of Industrial Furnace | Thickness: | 10-50mm | Width: | 400mm or 600mm |

| Length: | 600mm or 900 mm | Grade: | ST (Standard) | Chemical Composition: | AL2O3 46% |

| Ultimate Strength (≥ MPa): | 0.08-0.12 | Working Temperature: | 1000~1430℃ | Fiber Diameter: | 3-5 um |

| Thermal Conductivity: | 0.085-0.12W/m.k,low | Shrinkage (1800℉, 3h): | -3(24hours) | Place of Origin: | (Mainland) |

| Model Number: | ST | Brand Name: | color: | white | |

| asbestos: | no | thermal capacity: | low | flexibility and tear resistance: | high |

| thermal shock resistance: | high | packing: | inner plastic bag + outer carton |

Packaging & Delivery

| Packaging Detail: | carton packing and total 18 or 24 cartons in a pallet |

| Delivery Detail: | one week |

Specifications

1.Low thermal conductivity

2.No asbestos and anticorrosion.

3.Good flexibility , toughness

4.Excellent corrosion resistance.

Products Description

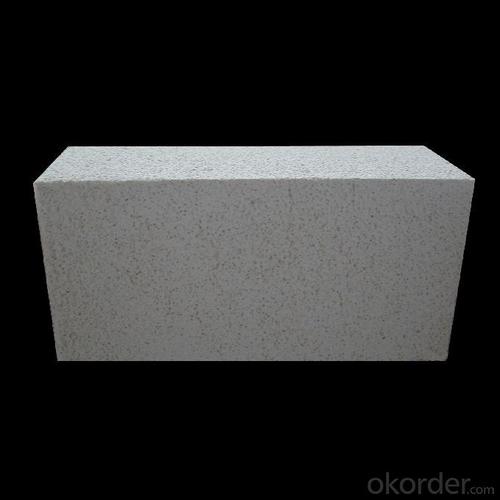

Ceramic fiber boards are rigid products made from ceramic fiber which are vacuum formed with

organic and inorganic binders, with or without mineral fillers . These are manufactured over a wide

range of grades densities and hardnesses.

The board is featured with high temperature stability , low thermal conductivity , even density, and

excellent resistance against thermal shock and chemical attack. They can be used as individual

component of furnace linings or as hard hot face layer as backup insulation.

Typical Application

1.Industrial furnace wall lining and bricking-up insulating layer

2.Heat insulation of high temperature and high-heat equipments

3.Heat insulation , fireproof and sound insulation of aerospace, ship building industries

4.Combustion chamber of boilers&heaters

Specification

Grade | Common | Standard | High Pure | High Aluminium | Zirconium | |

Classification Temperature(°C) | 1000 | 1260 | 1260 | 1300 | 1430 | |

Working Temperature(°C) | ≤1000 | 1150 | 1200 | 1260 | 1400 | |

Density(kg/m3) | 220-500 | 220-500 | 220-500 | 220-500 | 220-500 | |

Thermal conductivity by mean temp(W/m.k.)(density 285kg/m3) | 0.085(400°C) 0.132(800°C) 0.180(1000°C) | 0.085(400°C) 0.132(800°C) 0.180(1000°C) | 0.085(400°C) 0.132(800°C) 0.180(1000°C) | 0.085(400°C) 0.132(800°C) 0.180(1000°C) | 0.085(400°C) 0.132(800°C) 0.180(1000°C) | |

Compression strength(Mpa) | 0.5 | 0.5 | 0.5 | 0.5 | 0.5 | |

Chemical Composition (%) | Al2O3 | 44 | 46 | 47-49 | 52-55 | 32-33 |

Al2O3+SiO2 | 96 | 97 | 99 | 99 | - | |

Al2O3+SiO2+ZrO2 | - | - | - | - | 17-18 | |

ZrO2 | - | - | - | - | 15-17 | |

Fe2O3 | <1.2 | <1.0 | 0.2 | 0.2 | 0.2 | |

Na2O+K2O | ≤0.5 | ≤0.5 | 0.2 | 0.2 | 0.2 | |

Size (mm) | Other sizes and shapes on the working conditions | |||||

- Q: What method should be used to measure the thermal conductivity of fiberboard?

- Fiber board thermal conductivity of ceramic fiber board thermal conductivity information is mainly: ceramic fiber board thermal conductivity, thermal conductivity of ceramic fiber board price, thermal conductivity of ceramic fiber board wholesale, thermal conductivity of ceramic fiber board factory, discusses the protection method of hot plate test principle and method of MDF thermal conductivity and its relation with temperature; and analyzed the test error.

- Q: What are the standards for ceramic fiber boards?

- Ceramic fiber board currently only GB, and many production enterprises are also in accordance with GB to perform.

- Q: Ceramic fiber plate and aluminium silicate plate are chosen as lining materials

- Volume density is low: the density of the ceramic fiber lining is about 25% of the lining of the light heat insulation brick, about 10% of the lining of the light pouring material; adopting the fiber lining can greatly reduce the steel structure load of the furnace and prolong the service life of the furnace lining.

- Q: What are the sound-absorbing fiber boards?

- The theory on the absorption coefficient is the best sound-absorbing board sound-absorbing effect 1 (all suck, no reflections), but in reality, this material does not exist (black holes in the universe are the sound absorption coefficient is 1, which is completely absorbed)

- Q: What is the difference between ceramic fiber board and nano ceramic fiber board?

- The traditional ceramic fiber board has good heat insulation, high temperature resistance to certain characteristics, widely used in kiln products, but this tradition also has some shortages, low intensity, high temperature and high pressure, there are restrictions on the application of kiln stress.

- Q: What are the specifications of the ceramic fiber board?

- Ceramic fiber board density in conventional 300-350Kg/m over 350Kg/m to fand, fand fireproof plate series.

- Q: What are the differences between nano ceramic plate and ceramic fiber board?

- Nano ceramic plate for ceramic fiber with insulating board (felt), it is a functional material with excellent properties of aerogel insulation material and has a heat shielding function, adaptation to adhesive and a variety of inorganic elements in high temperature ceramic fiber as reinforcing material, through a special process preparation.

- Q: What are the uses of ceramic fiber boards?

- The ceramic fiber board, also called aluminum silicate fiber board or refractory fiber board, is divided into five grades according to the temperature grade:Fire dragon type ceramic fiber board HLGX-164Fire dragon standard ceramic fiber board HLGX-264Fire dragon high purity ceramic fiber board HLGX-364The dragon of high alumina ceramic fiber board HLGX-464Fire dragon contains zirconium type ceramic fiber board HLGX-564

- Q: Is there any difference between ceramic silicon fiber board and ceramic fiber board?

- Distinguishing.Ceramic silicon fiber board by long fiber silica, clay, talc, glaze etc. after 1150 degrees high temperature sintering, twenty-first Century revolutionary high-tech building materials. Characteristics: flexibility, high toughness, high strength, anti wind pressure; with homogeneous magnetized light ceramic surface, disposable, pores, anti pollution, is not easy to dust, mildew, antibacterial, deodorant, anti slip, no static, not fear of chemical erosion, such as acid, alkali, or even sulfate; fire, smoke, high temperature resistance, easy processing, cutting a hole.

- Q: How much pressure can the ceramic fiber board withstand?

- Ceramic fiber board has the characteristics of tough, high compressive strength, excellent resistance to high temperature and excellent supporting force. The compressive strength of ceramic fiber board increases with the increase of density of ceramic fiber board.

Send your message to us

Colored Ceramic Fiber Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m.t.

- Supply Capability:

- 10 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords