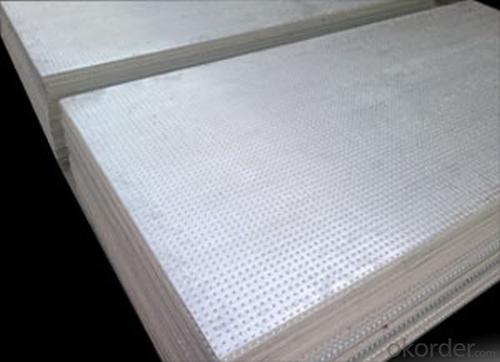

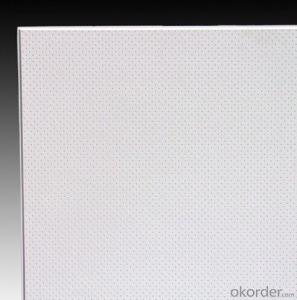

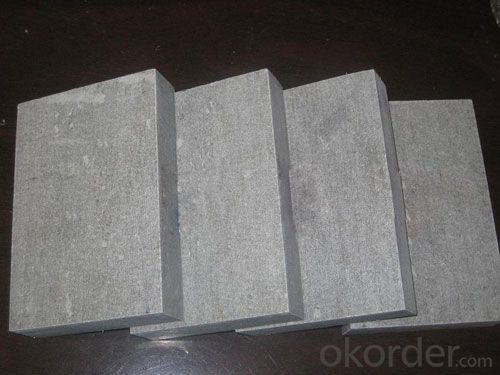

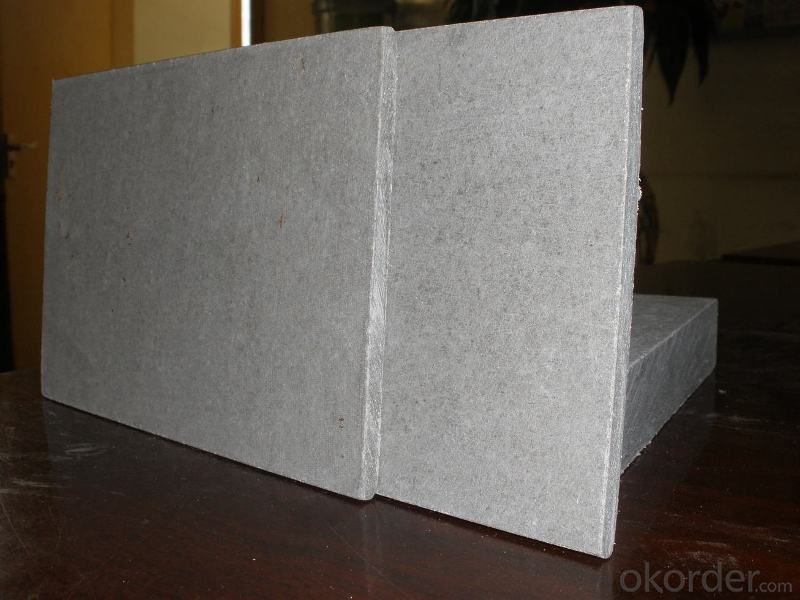

Exterior Wall Decorative Fiber Cement Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

High Density and Strength fiber cement board is a high quality calcium silicate architectural board reinforced with selected cellulose fibres and fillers.

The raw materials of fiber cement board are cellulose fiber, silicate cement, quartz sand, water and some additives.

It is 100% free from asbestos, sepiolite, inorganic fibres or formaldehyde.

Product Applications:

1.Indoor ceiling of industrial and resident building.

2.Partition of industrial and resident building.

3.The ceiling and partition of the bathroom and other wet condition building.

4.Indoor ceiling and partition as base board of the decoration for operation room,clean room of hospital or laboratory .

5.The fireproof board of the air passage.

6.Furniture or furniture's accessories.

Product Advantages:

1)excellent fire-proof

2)excellent damp-proof

3)Durability and long service life

4)high strength

5)stable dimensions

6)good heat and sound insulation

7)non-asbestos

8)mould resistant

9)no deformation

Main Product Features:

It's 100% free of asbestos, formaldehyde, benzene and other harmful substances and with excellent performance like high strength, large size, light weight, fire and water proofing, green and environmental friendly, high efficient and energy-saving. Therefore, this kind of new material is vigorously developed and recommended by the country.

Product Specifications:

FAQ:

1. Q:What is the different and most important point from other supplier?

A:We guarantee No asbestos if it has asbestos density will be more than 1.4g/cm3 what's more

3.2mm*3000*1220mm can be produced by us other suppliers can not do this size

2. Q:What are the advantages of your board?

A: outstanding light weight ,heat insulation, waterproof, fireproof, sound insulation, fast construction.

3. Q: Is the board fire resistant?

A: Yes, fire resistant 4 h , in the heat of 1000℃.actually it is noncombustible Class A1.

4. Q: Do you have any certificate to help us get government's approval?

A:China testing report and our laboratory' s testing by ourselves as your supporting document.

Because building standards are different in different countries, most of our customers buy the boards for testing and get approval by themselves.

5. Q: If we need samples for customer approval, will it be possible?

A: Of course we can.

6. Q:How to guarantee the quality?

A:Laboratory, integral testing process from raw materials to finished product until loading containers will be done by our factory.

Images:

- Q: I am looking for 1/2inch cement board is 3x5 sheets. Where is the cheapest place to get it?? THANKS!?

- GL Unless your a contractor and can get it at the local tile distributor HD or Lowes is your best bet. Just make sure you put it down according to manufactures specs.. ( Its the same for the American Tile Counsels)

- Q: I have an existing hardwood floor that I want to tile over (it's not in good condition). Can I put cement board then tile directly onto the hardwoods or do I need plywood on the hardwoods then cement board then tile? I don't want the floors to be 2 thick in addition to the hardwoods.

- Hillbill gave you good advice. I went to the site he recommended. It's straight up. I would add this; what you're looking for when you're done with the cementatious board is level. And, screws are better than nails on a wood floor.

- Q: Redoing my tub and shower tearing it out and instaling new walls and tile thanks.

- If you are installing ceramic tile then you definitely need to use cement board in the shower/tub area. Green board with ceramic tile would be okay for other parts of the bathroom walls, but not in the shower/tub. Green board is water resistant, but it is not really waterproof and should not be used in a shower. Cement board is not affected at all by water so it is great to use in shower.

- Q: I have a small bathroom approximately 4'x8' and I laid down and screwed in cement backer board. However, in my attention to detail I neglected to put down thin-set mortar underneath prior to screwing and taping down the board. I tried to pull the cement board up but I cant get under the tape that I mortared down to get to the screws. Am I in trouble here or can I go ahead and skip that and continue to tile? Please help...

- skip it continue on

- Q: What is the fiber used for cement foaming?

- Polypropylene staple fibers are chemically stable and only rely on changing the physical structure of concrete to improve the performance of concrete, which does not itself undergo any chemical reactions. With the concrete aggregate, admixture, admixture of cement mixed with its chemical and physical properties and stability, and good compatibility with the concrete material.

- Q: On the difference between the cement pressure plate, the fiber cement board, the Etter board

- From the definition of the plate I do not say too much, you can Baidu to see, here I mainly want to talk about the advantages and disadvantages between the three. Cement wet board wetting rate is relatively poor, easy to crack; fiber cement board because of its internal access to the plant fiber, wetting rate increased slightly, the Egyptian board also known as fiber reinforced concrete plate, Belgium is investing in the production of new sheet metal, Environmental protection (the only 100% of the country does not contain asbestos), high strength, and the same life with the building

- Q: What does the glass wire add to the cement?

- In order to increase the flexibility of cement components. After the cement is condensed, although the hardness is high, but toughness is insufficient, fragile and crackible, especially thin and thin strip type components, without glass, even the operation is a problem. The addition of glass to the microstructure of the cement can be pulled together, greatly increasing the impact resistance and bending resistance of components.

- Q: I know cement board to cement board is taped with thinset and fibatape, but what about the seam at the sides that meet drywall? How should these be taped. What Materials should be used?

- I use a self adhesive fiberglass tape over that seam, and apply 90 minute joint compound over the tape. I assume you are bringing your tile to, or just over that edge anyway. I also assume that that particular joint will be outside the shower curtain or glass, whichever you will be using.

- Q: I'm getting my bathroom shower tile installed and was told to get 4 sheets 1/2 thick backerboard with screws and I need to know if there is a difference between Cement Board and Backer Board?

- Same thing. Backer board is a general term. Backer board can be 1/4 thick. can be a wood substrate used for tile is certain circumstances ( not yours), it can be the Hardi board which is a cementrous type board. Basically a backer board any thing that goes under any tile . You should get the cement board for your application. And if your doing a shower and he/she didn t suggest it, a vapor barrier is also needed under the cement board.in the shower area. Any questions you e mail me through my avatar and check my qualifications there. GL

- Q: Our (rented) townhouse has a very bleak cement block basement. Right now the blocks are painted white and cream (and not in a pretty pattern) and the floor is painted dark gray. We want to use the basement as a fitness room and a crafting area for scrapbooking. The lighting is also terrible. What are some ways we can brighten up the space and make it more hospitable without doing any permanent construction (remember we are renting) or spending a lot of money?

- Because of your scrapbooking and since it is a basement you are going to want to consider storage options. Inexpensive shelving, either metal shelves or even sturdy boards and cinder blocks can be concealed behind curtains. I’ve even seen decorative shower curtains used for this. Curtains might help hide or break up some of the longer expanses of wall too. Take your time and watch clearance sales. You are probably going to want mirrors for your work out area. Inexpensive long, narrow dressing mirrors would be perfect for this and would also increase your lighting. They could be taken out of the cheap frames they come in and hung side by side or left in the frames for a more focused area. Some could even be hung side ways for a different effect on an adjoining wall. For the lighting I would think that an overhead in the work out area and halogen in your craft area would suffice and wouldn’t be too expensive. You don't want to scrimp on the lighting for your craft area, you will see the difference in the end product of your work if you do. All of these ideas leave you where anything you do have to purchase can easily be converted to another use in a new home. Good luck in your new place!

Send your message to us

Exterior Wall Decorative Fiber Cement Board

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10000 m²

- Supply Capability:

- 300000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords