Cement Board for Wall from China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container pc

- Supply Capability:

- 6000Pcs/Day pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

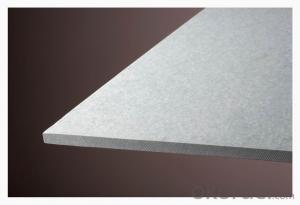

1.Product Features of Fiber Cement Board:

It is a light-weight and high-intensity building material which is characterized by convenience in construction, great performance for

processes like sawing, nailing without being warped or cracks. In addition, the surface of the boards can be painted or covered with tile or wallpaper, not afraid of insects and not self-heating.

The product has great thermal insulation, sound insulation, and endurance for temperature change, so it meets the working requirements of building construction, especially with it's good fire proof, explosion proof, and no emission of noxious fumes.

2.Technical Data of Fiber Cement Board:

Place of Origin: | AN HUI AND GUANGDONG China (Mainland) | Brand Name: | N | Model Number: | TCB-F8811 |

Type: | Non-Asbestos Fiber Cement Boards | Content of chloride ion: | 0% | Water content: | <10% |

Percentage of water swelling: | ≤0.25% | Thermal conductivity: | ≤0.20 W/mk | Fire Resistance: | Incombustibility A1 Class(GB8624-2006) |

Asbestos: | Asbestos free | Formaldehyde release: | No Formaldehyde | Basic color: | Brown |

Material of TCB fiber cement board: | 100% eco-friendly |

3.Specifications of Fiber Cement Board:

1) Thickness: 4 - 20mm

2) Normal Size: 1220*2440/1200*2400, with the maxium length 3.66m.

4.Usage of Fiber Cement Board:

The magnesium board is widely adoptable to partition and suspending ceiling in decoration of buildings. It is also absolutely suitable to the structure for heat preservation, sound insulation wall places with dampness, mobile partition, special class fire prevevention, sandwiched plate in fireproof- gate and packaging of equipment cases.

5.Packaging & Delivery of Fiber Cement Board:

1)Pieces with palletes or pieces loosely in the container.

2) Packed with 6-8 wood pallet in the container

- Q: i am going to be installing tile in my bathroom as a tub surround.i am wondering what backer board is needed. if i am using a membrane such as kerdi, is drywall a good enough backer or do i need cement board. if i need cement board, do i need the membrane? what products do you suggest for best installation. i will also be doing a walk in shower. are there any differences to be aware of compared to the tub surround shower style.

- Tile doesn't flex. Drywall does. You need a hard surface to lay tile, or the grout joints will crack, water will get in, and your tile will promptly fall off. Real tile backer board (the kind that's made out of fiber re-enforced cement) is the only decent solution for installing tile over a wood frame. Hardibacker or any other modern garbage designed to make something seemingly easier, just turns into a nasty headache a year later. Also be sure to use real thin-set mortar, and real grout. That adhesive grout is just acrylic caulking with some sand added, tiles will fall off if they get wet.

- Q: Will the cement board on the decoration be used to blow it directly?

- Can be directly putty putty. Its main material is cement, as long as you deal with the "calcium silicate board" and "calcium silicate board" between the joints. Seam to stay within a centimeter, and then fill a good tune against the plastic plaster gypsum. Plus a layer of special anti-crack bandage. This will extend its cracking time. good results.

- Q: How to apply waterproof material on the cement board?

- You can first brush again JS composite flexible waterproof coating, and then brush it again K11 waterproof coating paint; or brush twice straight JS composite elastic waterproof coating, so you can have a good crack resistance.

- Q: Bent cement board while installing onto floor...will it be ok?

- bent or cracked ? best that you get some cement and smooth it down or screw it to the floor if trhis is in prep for a tile floor then it will be OK .....

- Q: What are the brands of cement fiberboard

- At present, well-known brands are Eide board, the new element board, the East board, the German plate, easy and board, Zhejiang Greenbok Board Co., Ltd. 100 wood fiber cement board, sea dragon board, Hadi board, etc., the name of these plates are corresponding to the corresponding company name or brand.

- Q: How to maintain cement board

- The role of water conservation has two: First, in order to prevent cracking, the second is to ensure the full hydration of cement to complete the formation of cement strength. Of course, this method of watering is the general civil construction process. If it is engineering, then every day to be exhausted and can not accurately grasp the water, then how to do it? It will use special mortar, that is to add in the cement mortar admixture, so that the cement mortar has some different special features. In the special mortar, if you want to solve the above problem, the need to add hydroxypropyl methyl cellulose, this thing is called inside the water retaining agent, adding it, the cement mortar drying time is controlled, do not need to water every day Cured.

- Q: i glued a piece of regular printer paper to a piece of matboard as part of an art project. since i applied rubber cement to both the paper and the board, it bonded quite strongly. the problem is that now i have to remove the paper with the least amount of damage to the matboard. the paper is white and the board is black. its been over a week since i glued the two together. HELP!! i need this for school and it has to look good...any suggestions??im going to throw the paper away, so that can be damaged in the process. no problem.

- hair dryer to warm it and peel real slow...?

- Q: Can the cement board cut off the wall directly

- Mud wall can not be directly painted, need to do something to deal with, as follows: grass-roots treatment, the new cement mortar wall should not brush paint, the general need to wait six months after the oil. If you must paint, can be washed every 2 to 3 days a time to wash the wall, repeated many times. Brush oil before, but also the application of 10 to 20% of the dilute hydrochloric acid water coated once to neutralize the cement mortar in the remaining alkali, to be a moment after the water to wash the acid water, dry. So that the new cement mortar surface layer will not appear after the paint color, loss of light, from the volume of the phenomenon. Old cement mortar wall is best to use pig water and water into rice soup-like, with rows of rituals in the cement mortar wall full brush once, dry and then full of pig blood putty. General cement mortar wall paint before the surface to remove the dust clean, with plaster putty cracks, depression and other injuries filled. Paint is also a very critical step, the general wall can be twice brushing enamel, the second time to wait for the first pass and then brush. Oil brush in the brush when the direction of movement should be about to brush down, so brush evenly, the connector is not easy to see.

- Q: Is it okay to install ceramic tile on greenboard, or is cement board necessary?

- If the top layer of plywood is treated then there is no reason whatsoever to apply water proofing. If it isn't treated then there is always a small risk that large amounts of mold could develop in the plywood, but it is a small risk. I would pull up the cement board and put roofing felt under it. Or if I didn't want to take the time for about 80 dollars I can pick up a spray on waterproofing layer to the cement board that most tile flooring stores should carry. Tile membranes are good product, but somewhat expensive to use. Grout is sealed to protect the integrity of the grout and no other reason. A small amount of floor movement and water will have a direct path past the grout.

- Q: We have a home built in 1999 in the Gulf Coast area. On either side of the front entrance are flat cement board posts and above is a lintel. Last year I noticed the lintel was starting to have a gap between the brick and lintel itself as well as pulling away the top of one of the posts. I used heavy-duty exterior adhesive to try to reattach (used the ladder against it as pressure). I caulked and painted afterwards. Now, the separation is back, but much worse. I'm not even sure who to call to look at this. If I know why this happened, I could better figure out the next steps. Any ideas (I can find nothing through my research).

- Could be what the first poster suggests. Without actually seeing it, it's really hard to tell. Are there other places in the home that are suddenly not level? Or things that used to be square now not square? That's usually a good indication of a foundation issue. The first thought that popped into my head was a moisture problem from some where. Most likely a leak above the area. Could be very small but over time is creating issues within the wall and the cement board will have a tendency to attract the moisture. Even a bad seal around a window or the soffit area above will create an issue such as you are experiencing.

1. Manufacturer Overview

| Location | Feicheng city, China |

| Year Established | 1955 |

| Annual Output Value | Below US$1 Million |

| Main Markets | 55.00% China Market 15.00% Mid East Market 9.00% Africa Market 7.00% Korea Market 5.00% Europe Market 5.00% Austraila Market 4.00% Eastern Asia Market |

| Company Certifications | ISO 9001:2000 Certificate , Green Building Materials Certificate |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Qingdao PORT |

| Export Percentage | 1% - 10% |

| No.of Employees in Trade Department | 20 PEOPLE |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 270,000 square meters |

| No. of Production Lines | ABOVE 4 LINES |

| Contract Manufacturing | Design Service Offered ,Quality control offered |

| Product Price Range | MODERATE PRICE |

Send your message to us

Cement Board for Wall from China

- Loading Port:

- China Main Port

- Payment Terms:

- TT or L/C

- Min Order Qty:

- 1Container pc

- Supply Capability:

- 6000Pcs/Day pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords