Fireproof Fiber Cement Board Fireproof Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Applications:

Fireproof fiber Cement Board

The compressed machine is 14000 tons, So we can produce density over 1600kg/m3. 100% Non asbestos

Product Advantages:

Fireproof fiber Cement Board

Headerboard high density fiber cement board is 100% free of asbestos. The compressed machine is14000tons. So we can produce density over 1600kg/m3.Thickness from 4mm-30mm, Standsize is 1220*2440, size can be customized according to your requirement.

The production line was introduced from Germany. There are total two production lines now. Production capacity is 20 million square meters per year. We can send you boards earlier than other supplier.

Main Product Features:

Product Name | Fireproof fiber Cement Board |

Raw Materials | Cellulose Fiber, Quartz Sand, Portland Cement |

Standard Size | 1220X2440MM / 1200X2400MM |

Maxium Width | 1250MM |

Maximum Length | 4880MM |

Thickness | 4-30MM |

Density | 1.5-1.7G/CM3; 1.2-1.4G/CM3 / 1.4-1.5G/CM3 |

Wet Expansion | ≤0.23% |

Water Absorption | ≤25% |

Incombustibility | Incombustible Class A1 |

Water Penetration | Back side without water drop after 24 hours |

Flexural Strength | Air dried condition: ≥18; Saturated Condition: ≥14 |

Radioactivity | Decorative materials Class A |

Frost Resistance | No layers and no cracks after 25 cycles under freezing and thawing |

Asbestos | 100% free of asbestos |

Certification | ISO, CE, SGS |

Packaging | Standard wooden pallet |

Trade Terms | FOB, CNF, CIF |

Payment Terms | T/T, Irrevocable L/C at sight |

Delivery Time | Within 15 days if stock not available |

Main Characteristic | Environmental friendly materials |

Excellent Strength and toughness | |

Waterproofing and fireproofing | |

Antisepsis and moth-proofing | |

Good acoustic insulation and weather resistance | |

Good thermal and heat insulation | |

Durability and long lifetime | |

Application | Exterior decoration panel |

Intergrative facade panel for exterior wall thermal insulation | |

Interior wall decoration panel | |

Flooring for loft interlayer, container house, light steel villa | |

For subway, tunnel,baseboard, outdoor furniture | |

Roofing sheet | |

Thinner lining board for stone |

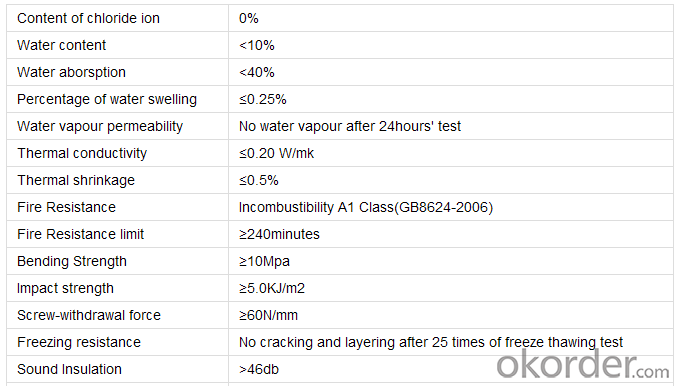

Product Specifications:

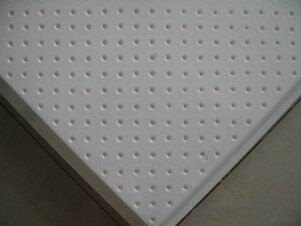

Images:

- Q: If properly waterproofed/installed, will extreme temperatures still gradually warp cement backer boards and crack tile flooring? Thank you.

- Ya don't need backer board for tile floors. A good coat of floor leveling mix (definitely not self-levelling whatever the name says) and a good mortar base with 1/4 trowel will work just fine. But durok is a cement product so it would only distort due to expansion and contraction which proper installation would minimize.

- Q: i would also like to know what products might help me. Thanks :) Oh, and the type of board i got is called hardi-bord... i didnt know if that might help.

- wow, some of these answers are terrible, I like the one where the guy says dont worry about taping and mudding the seams or the other one that said just double up the backerboard lol. Anyway, you should have a vapor barrier of some sort. Since you already put up the backerboard, you should tape and mud the seams then put a coat of Redgard(made by Custom Building Products, at Home Depot) over the backerboard. You can paint it on, its very easy. As far as the electrical box, if it was dry before then I would leave it as long as its not wrapping around any plumbing pipes.

- Q: An exhibition, you can use the cement board to do arc shape of the wall? If so, what about the specific building steps?

- Light steel keel generally with 75 specifications if you do not understand anything to find a decoration under the Advisory company you ask you on the Internet you can not understand

- Q: Installing a shower in my basement, and am framing around a fiberglass 36 square shower base. should I put it flush against the frame and then attach cement board (it will overhang) or leave room to slide cement board between base and frame? Thanks!

- I saw another answer that tells you to leave it above the flange of the base, but here is the problem with that and how I do it. If you leave it short of the base, there is now a gap however high the flange is with nothing to support the tile OR a place for the grout the sit because there is a void behind the tile. What I do is measure the thickness of the base ( usually 1/4) and then I rip a filler strip the same thickness as the flange. I nail it to the studs from the flange up to where you are going to stop the backer board or to the ceiling and then attach Hardibacker or Wonderboard to the furred out studs. Now the substrate can be installed 1/4 inch off the bottom of the base unit to avoid water wicking up and the tile has a full backing to within 1/4 of the base as well as the grout goes all the way in instead of sitting only BETWEEN the tiles as it would if you left it 1 1/2 up off the bottom sitting on the top of the flange. The only adjustment you will need to do is set the shower valve out whatever the thickness of the furring strips you add so it finishes on the tile surface to the manufacturers specs.

- Q: I have a bare concrete/cement floor. After I installed Travertine on one section, it is almost 1/2 inch above the floor. Now, I want to continue to install the other section of the floor with laminate wood, but the floor is too low compared to the travertine floor. The question are: Can I put down a particle board over the concrete/cement floor, then a foam pad (moisture barrier), then laminate wood?Will the particle board absorb water then swell up?Or do I need to put down the moisture barrier foam first, then particle, then laminate wood?If I am not using the particle board, the laminate wood floor will be about 1/8 lower than the travertine floor. is it ok?

- Do NOT use particle board. There is no reason, as the laminate can be laid over the concrete with the proper padding. The particle board may swell and cause you issues down the road. Check the instructions on the flooring. Some require a plastic vapor barrier under them, while others only need the padding. 1/8 is not a big deal. The transition strip will bridge the difference. Be sure to check for peaks and valleys in the concrete, and fill in low spots. This will prevent the tongues on the planks from snapping off, leaving gaps in the floor. Allow the laminate to acclimate to the basement for a week or so before installing. Hope this helps. EDIT: You don't need anything under the flooring except vapor barrier or padding. They are designed to be able to be installed on a concrete base. Good luck.

- Q: Do you need to finish a cement board for a shower like you would if it were drywall?

- Yes..2 reasons..so moisture cant get behind the wall...and it's prevent fire from spreading faster if that wall were to burn. Use dura bond and seam tape just like you would with drywall.

- Q: I have a walk in closet with plywood pieces for a floor. Don't I need cement board installed before putting in wood flooring? Thanks for your help!!

- we okorder and search

- Q: is there a spray on cement moisture barrier to use under laminate flooring?

- There are water block paints and such... but the cost would be too exorbitant for what you need to accomplish. ALSO.. most laminate floor manufacturers state that a 6 mil plastic sheet vapor barrier is what they require, when installing their products on concrete. (This goes on the concrete, then the foam underpad goes over the plastic sheeting) You can buy 6 mil plastic by the roll.... 10ft x 25ft, or longer.. in clear or black, and isnt that expensive. It's what the manufacturers suggest, I'd stick with it, or you're going to void your flooring warranty.

- Q: I've done the hard way - bunches of expensive special screws. I found that to be expensive and time consuming (and therefore back breaking). It seems like it takes just as long to do the backer board as it does to do all the remaining steps with the tile. Can I use nails? If so, what kind? Thinset and nails? The subfloor is plywood with old vinyl tiles, I have no intention of remove the old vinyl tiles first. Please reply if you have personal experience with an alternative. Thanks!

- If you want it to last you should thin set AND screw the cement board down. Cement board is not just used in wet areas. It is a dimensionally stable product and properly installed it will keep your tile and grout from cracking and/or coming loose. If you try to scimp on the prep then you will be wasting your time and money. Some installers do nail it down but bare in mind that this will void any warranty. Don't forget to tape the joints too. If the vinyl tiles are down tight and height room to room is not an issue then leave it in place and go over top.

- Q: do i need to put down cement board on concrete before laying tile?

- no just clean and smooth the floor see flash patch .

Send your message to us

Fireproof Fiber Cement Board Fireproof Fiber Cement Board

- Loading Port:

- China Main Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords