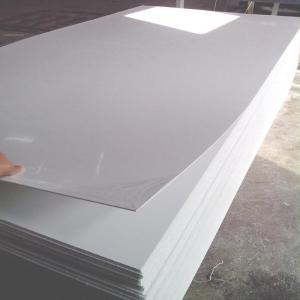

UV coating board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120000pcs pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

LUTAI coating board is a slap-up interior&exterior decorative material with high -tech green enviromental protection.Based on the multiple inorganic material by high pressure. The surface adopt spefical technics to coating UV curable fluorocarbon dope. And will have a refreshing experience due to rich color,lively line .better effect of simulation.Enviromentalprotection,unvioresistant,alkali&acid-resistance ,corrosion-resistance,firproof,duration weather ablity,dampproof, durability,stable color, bacteriostat,weather resistance .

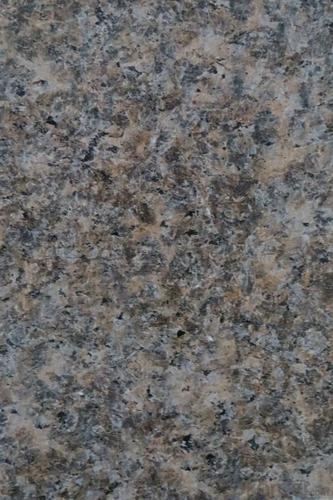

There are four types of this product .They are PURE COLOR SERIES , STONE TEXTURE SERIES ,RHINESTONE SERIES ,WOOD GRAIN SERIES .

TEST ITEMS | RESULT | ||

PHYSICAL MECHANICS PROPERTY | DENSITY | ≥ 1.4G/CM3 | |

WATER CONTENT | ≤ 10% | ||

WATER ABSORPTION | ≤ 28% | ||

WATER IMPERMEABILITY | The duration of the test shall be 24h, traces of moisture may appear on the under surface of the sheet , but in no instance shall there be any formation of drops of water | ||

IMPACT RESISTANCE | The surface of sheet doesn’t have penetrating crack when using once falling ball impact test | ||

BENDING STRENGTH | >16MPA | ||

FREEZING RESISTANCE | Without no crack and delamination after 25 times freeze thaw recycling test . | ||

INCOMBUSTIBLE | GB8624 A GRADE | ||

RADIOACTIVITY | Internal exposure index | ≤ 1.0IRa | |

External exposure index | ≤ 1.0Iγ | ||

COATING QUALITY | GLOSS DEVIATION (60) | ≤ 10 | |

ADHESIVE FORCE ,LEVEL | ≤ 1 | ||

PENCIL HARDNESS | ≥2H | ||

MORTAR RESISTANCE,24H | No changing | ||

WATER RESISTANCE,168H | No abnormalities | ||

ACID-BASE RESISTANCE,168H | No abnormalities | ||

DAMP AND HOT RESISTANCE,1000H | No bubbles , no rust, no crack | ||

COLD RESISTANCE OF THE HEAT CYCLE (TEN TIMES ) | No abnormalities | ||

POLLUTION RESISTANCE | PASS | ||

DIRT-PICK UP RESISTANCE | ≤ 10% | ||

RINSING RESISTANCE (TIMES) | ≥10000 | ||

SOLVENT(BUTANONE) WIPING TEST (TIMES) | ≥100 | ||

SOLT FOG RESISTANCE ,4000H | No bubbles , no rust, no crack | ||

ARTIFICIAL WEATHERING AGING RESISTANCE ,4000H | No bubbles , no falling off, no crack | ||

- Q: Hello, my husband and myself are remodeling our bathroom....here's the question... we removed hideous vinyle tiles and underneath is the cement floor with thin layer of black adhesive from the tiles....the floor is pretty sound except for a small crack in cement by the entry door.... should we fix the crack and tile over the cement? or thin set 1/4''cement fiber board to the floor and tile over that? and if we do use the fiber board is the thin set enough to hold it down? we can't really screw/nail it cuz subfloor is cement. Any help is appreciated! Thanks!

- the best way would be to use red guard as a waterproofing and anti fracture membrane this will help to control cracking in the future, use liberally, you may set tile using versa bond flex white mortar aka thinset right over the concrete.this type of thinset is designed to have a bit of flex to it to help with movement or cracking of tiles. use 1/4 inch trowel,

- Q: I removed old tile from my bathroom walls as well as the old vinyl flooring. Underneath the vinyl was cement backerboard, which is good. But all around the outer edges where the wall tile used to be, is a 1 inch gap where the floor board are showing. How do I get this gap filled? Do I need to rip up the old cement backerboard and start over? Can I cut small strips of new backerboard to slip in the crevice? Is there a compound I can fill the gap with? Any help out there?

- Fill it with thin-set. There won't be any pressure applied along the wall. Fill with thin-set and wait 24 hours to dry before installing tile. Just make sure to smooth it out and it's level with rest of the backer-board floor.

- Q: Bathroom wood panels on the aluminum plate opened, how do? Bathroom wood panels on the aluminum plate opened, how do?

- The bathroom is relatively dark and dark, available light steel keel aluminum plate hanging ceiling, light and durable moisture-resistant, and not easy to deformation, the price is not expensive.

- Q: Can you hang outside garden wall hangings on fiber cement board siding and what is the best way to do it?

- Decorative Cement Board

- Q: I'm ready to tile my kitchen soon. My husband and I have torn up the carpet and 2 layers of linoleum, leaving only some leftover glue from the linoleum and the wood sub floor. Do we really need to lay cement board over the wood sub floor or can we just go ahead and tile right on the wood? (FYI: it will be either ceramic or porcelain tile)

- I take you're in in the USA so not sure you can get an elastomeric adhesive such as BAL fast flex. If your sub floor is sound and deflection free you could use this.

- Q: Iam building a dry stack wall and the home store said to use cement broad and wire mess .

- You mean wire mesh. Yes, you need that.

- Q: I'm looking to install siding on my home and just looking for answers to the obvious concerns....... maintenance, longevity, and energy efficiency>

- From an evergy efficency standpoint, neither has enough R value to even enter into the decision. With vinyl siding, you can add a rigid foam insulation behind the siding prior to installation that will increase the R value and some high end vinly comes with a foam insulation already laminated to the back. Hardi Board makes a pre-painted siding that has a 15 year warranty on the paint job. It doesn't ding, crack, or blow off in a strong wind. Plus, it looks like authentic wood siding (but much less expensive) However, you will pay substantially more than vinyl siding. For most people it comes down to price. When given all the facts, fiber cement is by far the superior product but if its not in your budget then vinyl siding is a respectable alternative.

- Q: Can anyone suggest a good way to cut small pieces (i.e. 2-4) of Hardiebacker and make it break cleanly? I can't seem to get it to break off easily unless it's bigger piece... and I was told not to use a power tool (i.e. circular saw) as it would create a ton of dust, which could be bad to breath in.

- When trying to snap off the smaller pieces, it helps to lay the board on a 2x4 or other straight-cornered object, with the score line parallel and directly above the edge, and facing up. Score extra deep to help control the break. Hold the larger section of sheet tight to the 2x4, and press down on the 2-4 part, and it should hinge along the corner of the 2x4. If any small chunks stick out of the broken edge, you can rasp them off with a rasp, a utility knife, or even by rubbing the edge on rough concrete. The diamond blade method is the most sure way to create a straight cut, and does make a lot of dust, which requires wearing a dust mask, but you can also reduce the dust by holding a vacuum along the front edge of the blade as you cut, to suck up as much dust as possible.

- Q: i'm replacing the tiles in my tub area and i'm changing the existing wall to cement board. how do i join it with the rest of the bathroom wall that's texture?

- find the studs to screw into and use liquid nails

- Q: i notice that the white cement is not sticking properly to my ceiling..anyone could advise me on this.. is it due to the surface of the ceiling or i did not blend it properly????

- there is a product use for gibson board call spacking or spackling , bonding agent or something llike that.Apply in the crack and let it dry, it will change color when its dry from pink to white,then you use sand paper to remove excess of bonding or leave it like that.

Send your message to us

UV coating board

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- 120000pcs pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords