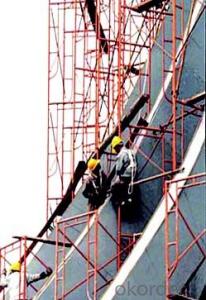

Scaffolding Wheel Formwork Walk Through Scaffolding Frames Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Scaffolding Wheel Formwork Walk Through Scaffolding Frames Made in China

Plastic Formwork Concrete Formwork Wedge Lock Scaffolding Formwork System High Quality

Developing with new technology materials, steel formworks is no longer a must in construction concrete process. More and more buildings are established with plastic formworks. And workers love this new formworks much more.

The advantages of plastic formworks:

1.First of all--light

Yes it is the first advantage of plastic formwork. It wins the great praise of both contractors and workers.

The biggest panel is 120×1500px,weights 10.5kg only. It can be lift and set up by one person easily, which means there is no need for cranes on site.Saves a lot of cost and time.

2.Easy set up

Different size of panels can firmly locked by simply turn the special handles to 90 degree. The Panels has rib on the back, which makes the system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

3.Modularity

Modular formworks composed by different size of panels,the main item is 120×1500px panel,which is used for the large area of walls and slabs. There are also small size of panels like 10×1500px,20×1500pxcm,25×1500px,inner corner 20×20×1500px and outer corner 10×5×1500px.Due to the variety of panel size, the system can form almost all size walls 120×1500px panel of multiply by 125px. The material of modular formwork is PC-ABS mixed with special glass fibers which enable panels to hold high pressures.

4.Strength

The handles are made by high strength Nilon, each panel locked by at least 4 handles, which makes the whole system strong enough to pour 1000px walls.

Scaffolding Wheel Formwork Walk Through Scaffolding Frames Made in China

Scaffolding Wheel Formwork Walk Through Scaffolding Frames Made in China

Packing

in bulk or in bundle, or as requested

Shipping

15-20 Days.

Normally small orders, it needs just 15-20 business days to the port. For goods with stock, it would be even shoter.

Other scaffolding & formwork products:

(1) Scaffolding System:

Including Ringlock Scaffolding System and accessories; Cuplock Scaffolding System and accessories; Kwikstage Scaffolding System and accessories; Haki Scaffolding System and accessories;

(2) Scaffolding Frame & Accessories:

Including Walk Through Frame Scaffolding; Ladder Frame Scaffolding; Accessories; we also can make scaffolding according to your samples or drawings.

(3) Scaffolding Couplers/Clamps:

We can produce all kinds of forged and pressed couplers, including British type couplers, American type couplers, German type couplers, Italian type couplers ,fence couplers, BRC coplers and so on. We also can produce according to your drawings or samples.

FAQ Scaffolding Wheel Formwork Walk Through Scaffolding Frames Made in China

We have organized several common questions for our clients,may help you sincerely:

①How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

- Q: What are the common sizes of steel frame formwork panels?

- The common sizes of steel frame formwork panels vary depending on the specific construction project and the requirements of the concrete structure being built. However, there are a few standard sizes that are commonly used in the industry. One of the most common sizes for steel frame formwork panels is 1.2 meters by 2.4 meters (4 feet by 8 feet). This size is widely used and readily available, making it a popular choice for many construction projects. These panels are typically lightweight and easy to handle, making them suitable for a wide range of applications. Another common size for steel frame formwork panels is 1.5 meters by 3 meters (5 feet by 10 feet). These larger panels are often used for bigger concrete structures or projects that require a larger surface area to be covered. Despite their larger size, these panels are still relatively easy to handle and install. In addition to these standard sizes, custom sizes of steel frame formwork panels can also be manufactured to meet the specific needs of a construction project. This allows for greater flexibility and adaptability, ensuring that the formwork system can be tailored to the unique requirements of the concrete structure being built. It is important to note that the sizes mentioned above are just some of the common options available for steel frame formwork panels. The actual sizes used in a construction project will depend on various factors such as the design and dimensions of the concrete structure, the available space on the construction site, and the preferences of the construction team.

- Q: What are the different types of reinforcement systems used with steel frame formwork?

- Construction projects utilize various reinforcement systems with steel frame formwork to enhance strength and stability. These systems ensure the formwork's ability to withstand the weight and pressure exerted by the poured concrete. An example of a commonly employed reinforcement system for steel frame formwork is the incorporation of steel bars or rods. These bars are positioned both horizontally and vertically within the formwork, creating a grid-like pattern. This arrangement serves to evenly distribute the concrete's weight and pressure, preventing any collapse or deformation of the formwork. Another reinforcement system employed with steel frame formwork involves the utilization of steel mesh or wire. This mesh or wire is inserted into the formwork to provide further reinforcement and prevent the concrete from cracking or breaking under pressure. Ties or clips are used to secure the mesh or wire in place, ensuring its stability during the pouring and curing process. Besides steel bars and mesh, other reinforcement systems for steel frame formwork include the use of fiber-reinforced polymers (FRPs) and plastic or composite materials. These lightweight yet robust materials offer excellent reinforcement properties. FRPs are particularly beneficial in scenarios requiring corrosion resistance, as they are not susceptible to rust or degradation. Ultimately, the choice of reinforcement system for steel frame formwork depends on various factors, including project requirements, concrete type and load, and desired strength and stability levels. Consulting a structural engineer or construction professional is crucial to determine the most suitable reinforcement system for a specific project.

- Q: Can steel frame formwork be used for retaining walls or foundation structures?

- Yes, steel frame formwork can be used for both retaining walls and foundation structures. Steel frame formwork offers a high level of strength and durability, making it suitable for these types of structural elements. Additionally, it provides the necessary support and stability required during the construction process.

- Q: How does steel frame formwork contribute to faster construction times?

- There are several ways in which steel frame formwork speeds up construction. Firstly, steel formwork is incredibly durable and can withstand the pressure and weight of concrete without warping or deforming. This means it can be used multiple times, saving time and effort during installation and removal. In addition, steel frame formwork systems are designed to be easily assembled and disassembled, allowing for quick construction and dismantling. These systems are modular, meaning adjustments and modifications can be made easily, saving time and ensuring accuracy. Furthermore, steel formwork provides a smooth and even surface finish, eliminating the need for additional plastering or finishing work. This saves both time and money during the final stages of construction. Moreover, steel frame formwork allows for efficient pouring and curing of concrete. The tight joints and secure connections between the formwork elements ensure the concrete is properly contained and shaped during pouring. This eliminates the need for additional support structures and reduces the risk of concrete leakage or collapse. Overall, the strength, reusability, easy assembly, and efficient pouring capabilities of steel frame formwork all contribute to faster construction times by reducing labor and time for formwork installation, providing a smooth surface finish, and facilitating rapid concrete pouring and curing processes.

- Q: How does steel frame formwork contribute to the overall durability of a structure?

- There are several ways in which steel frame formwork contributes to the overall durability of a structure. To begin with, steel possesses high strength and resistance to deformation, making it a reliable material for bearing heavy loads and external forces. This strength enables the steel frame formwork to support the weight of concrete during construction, guaranteeing the structure's integrity and stability. Moreover, steel is highly durable and exhibits excellent corrosion resistance. Unlike materials like wood or aluminum, steel does not rot or rust easily, which could weaken the structure over time. This resistance to corrosion ensures that the steel frame formwork remains structurally sound and maintains its strength for an extended period. Furthermore, steel frame formwork offers a high level of precision and accuracy in construction. The rigid and robust nature of steel allows for precise alignment and positioning of the formwork, resulting in accurate and consistent placement of concrete. This precision not only enhances the structure's overall aesthetics but also increases its durability by ensuring proper alignment of all elements, reducing the risk of structural failure. Additionally, steel frame formwork is reusable, further enhancing its contribution to a structure's durability. Unlike traditional formwork materials such as wood, which are often single-use and require frequent replacement, steel formwork can be dismantled and reused multiple times. This not only reduces construction costs but also minimizes waste and environmental impact. The ability to reuse steel formwork ensures that the structure's integrity is maintained throughout its lifespan, even during renovation or repair work. In conclusion, steel frame formwork plays a crucial role in enhancing the overall durability of a structure. Its high strength, corrosion resistance, precision, and reusability make it an ideal choice for supporting concrete during construction and ensuring the long-term stability and structural integrity of the building.

- Q: How does steel frame formwork contribute to the overall fire resistance of a structure?

- Steel frame formwork contributes to the overall fire resistance of a structure in several ways. Firstly, steel is known for its high melting point and excellent heat resistance. This means that it can withstand high temperatures for longer periods of time before it starts to lose its structural integrity. In the event of a fire, the steel frame formwork acts as a barrier, protecting the structure from the direct heat of the flames and preventing the spread of fire to other parts of the building. Additionally, steel frame formwork has the ability to retain its strength even at elevated temperatures. This is crucial in maintaining the structural stability of the building during a fire. Unlike other construction materials, such as wood or concrete, steel does not weaken or lose its load-bearing capacity when exposed to high temperatures. This ensures that the structure remains intact and reduces the risk of collapse. Moreover, steel is non-combustible, meaning it does not ignite or contribute fuel to a fire. This characteristic further enhances the fire resistance of the structure as it helps to contain the fire within a specific area and prevents it from spreading to other parts of the building. By confining the fire to a limited space, steel frame formwork allows for easier and safer evacuation of occupants and provides more time for firefighting efforts. Furthermore, steel frame formwork is often used in conjunction with fire-resistant materials, such as fire-resistant insulation and fire-rated coatings. These additional measures enhance the fire resistance of the structure by providing an extra layer of protection against the heat and flames. The combination of steel frame formwork and fire-resistant materials creates a robust fire-resistant system that significantly improves the overall fire safety of the building. In conclusion, steel frame formwork contributes to the overall fire resistance of a structure by providing a strong and heat-resistant barrier, retaining its load-bearing capacity at high temperatures, being non-combustible, and working in tandem with fire-resistant materials. By incorporating steel frame formwork into the construction process, the risk of fire-related damage and the potential for loss of life can be greatly reduced.

- Q: How does steel frame formwork prevent the formation of concrete segregation during pouring?

- The strong and rigid structure of steel frame formwork effectively prevents concrete segregation by securely holding the concrete in place and avoiding any movement or separation of aggregate particles from the cement paste. To begin with, the stability provided by the steel frame formwork ensures that there is no deformation or bulging during the pouring process. Consequently, the concrete is poured evenly and uniformly, eliminating any gaps or voids that might result in segregation. Furthermore, the steel frame formwork is usually lined with smooth materials like plywood. This smooth surface minimizes friction between the formwork and the concrete, facilitating a consistent and uniform flow. Consequently, there is a reduced likelihood of aggregate particles settling or segregating from the cement paste. Moreover, the steel frame formwork is meticulously designed with tight joints and connections, preventing any leakage or seepage of the concrete. By doing so, excess water or cement paste is prevented from escaping, which could cause the aggregate particles to settle at the bottom and create segregation. In summary, the steel frame formwork's strong and rigid structure, combined with its smooth surface and tight joints, ensures proper containment and pouring of the concrete. This comprehensive approach promotes a homogeneous mixture of cement, aggregate, and water throughout the pouring process, effectively preventing the formation of concrete segregation.

- Q: How does steel frame formwork improve the quality of concrete?

- There are several ways in which the quality of concrete is improved by steel frame formwork. To begin with, the use of steel frame formwork ensures that the concrete maintains its shape and form throughout the curing process, thanks to its stable and rigid structure. This prevents any deformation or warping, resulting in a final product that is more accurate and precise. Furthermore, the steel frame formwork allows for easy and efficient placement of reinforcement bars within the concrete. This is crucial for enhancing the structural integrity and strength of the concrete. By providing a secure framework, the steel frame holds the reinforcement bars in place, preventing displacement or movement during pouring and curing. In addition, steel frame formwork enables precise control over the pouring of the concrete, ensuring a consistent and uniform distribution of the mixture. This eliminates any voids or air pockets, resulting in a final product that is denser and more durable. Moreover, the use of steel frame formwork creates a smooth and even surface for the concrete, reducing the need for additional finishing or surface treatments. This not only saves time and resources but also improves the overall aesthetics of the concrete. In summary, steel frame formwork is essential for improving the quality of concrete by providing stability, facilitating the placement of reinforcement bars, allowing for precise pouring, and creating a smooth surface finish.

- Q: What are the different methods of fixing and anchoring steel frame formwork?

- There are several methods for fixing and anchoring steel frame formwork. Some common methods include using steel nails or screws to secure the formwork to wooden or metal stakes driven into the ground. Another method is using adjustable clamps or brackets to attach the formwork to existing structures or columns. Additionally, steel frame formwork can be anchored by using steel rods or bolts to connect the formwork to the concrete foundation or surrounding structures. These methods provide stability and ensure that the formwork remains in place during the concrete pouring and setting process.

- Q: Are there any specific considerations for using steel frame formwork in educational buildings?

- Yes, there are specific considerations for using steel frame formwork in educational buildings. Firstly, steel frame formwork offers high strength and durability, making it suitable for withstanding heavy loads and withstanding long-term use in educational buildings. Secondly, steel frame formwork allows for flexibility in design and construction, enabling the creation of various shapes and sizes of classrooms, laboratories, and other educational spaces. Additionally, steel frame formwork provides fire resistance, which is crucial for ensuring the safety of occupants in educational buildings. Lastly, steel frame formwork allows for faster construction, reducing the overall construction time of educational buildings.

Send your message to us

Scaffolding Wheel Formwork Walk Through Scaffolding Frames Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10000 set

- Supply Capability:

- 50000 set/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords