750 Series Adjustable Steel Frame Formwork with Special hollow steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

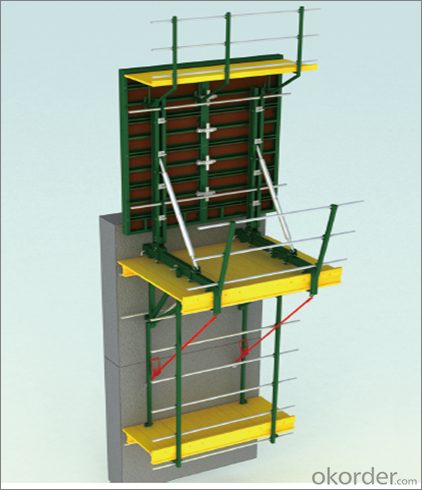

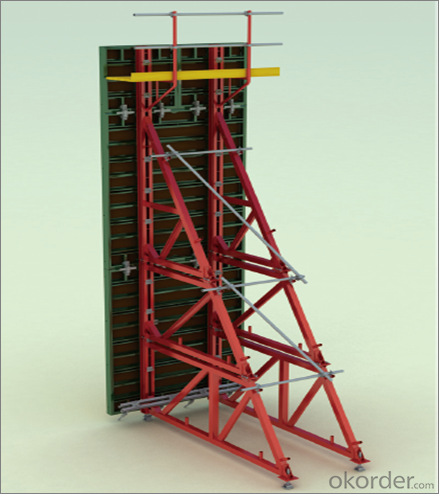

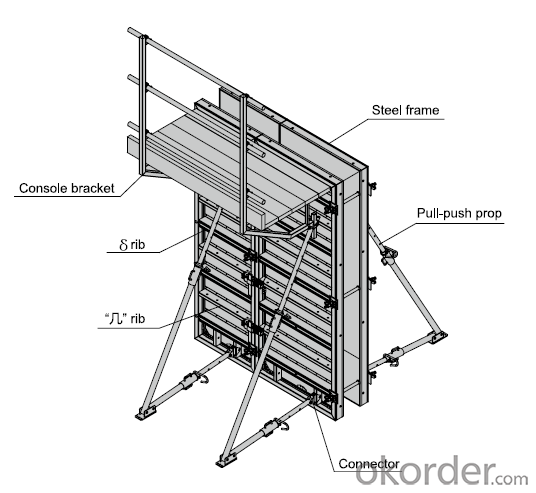

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

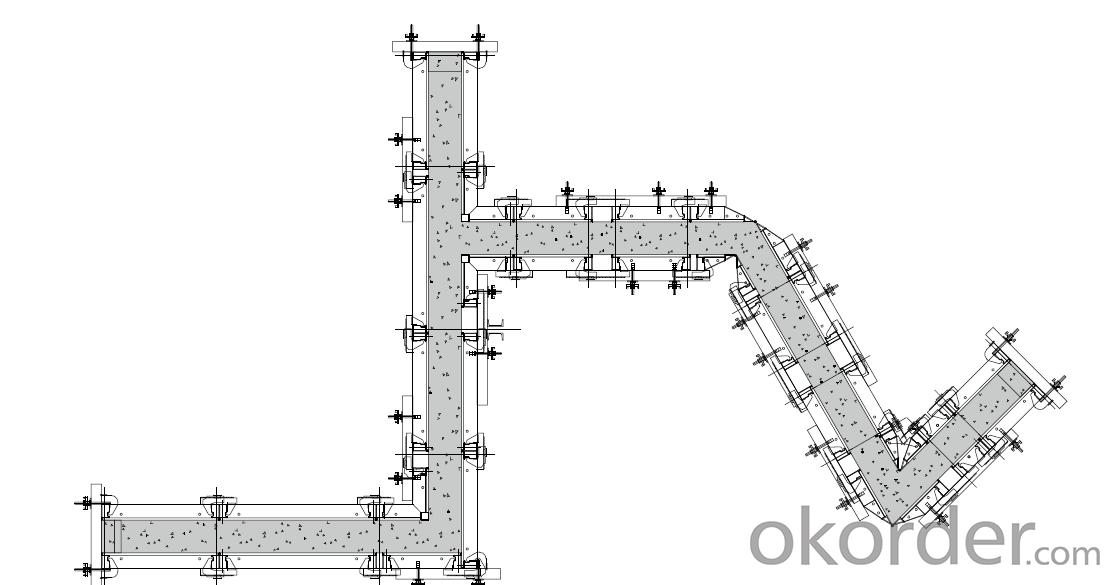

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: What types of concrete structures can be formed using steel frame formwork?

- Steel frame formwork is a versatile construction technique that can be utilized to construct various types of concrete structures. Some of the common uses of steel frame formwork include: 1. Tall buildings: Steel frame formwork is an ideal option for erecting high-rise buildings due to its exceptional strength and stability. It provides the necessary support to pour concrete at significant heights, ensuring the structural integrity of the building. 2. Bridges and flyovers: Steel frame formwork is extensively used in the construction of bridges and flyovers. It offers a robust framework that can withstand heavy loads and allows for the creation of complex shapes and curves required in these structures. 3. Industrial structures: Steel frame formwork is commonly employed in the construction of industrial buildings such as factories, warehouses, and manufacturing plants. Its durability and flexibility make it suitable for accommodating large open spaces and heavy machinery. 4. Retaining walls: Steel frame formwork is an excellent choice for building retaining walls. It provides a strong and rigid structure capable of withstanding the pressure exerted by the retained soil, ensuring the stability of the wall. 5. Water tanks and reservoirs: Steel frame formwork is frequently used in the construction of water tanks and reservoirs. Its ability to create watertight structures makes it suitable for storing water, ensuring there are no leaks or seepages. 6. Tunnels and underground structures: Steel frame formwork is utilized in the construction of tunnels and underground structures due to its capacity to withstand high pressure and provide a secure framework for pouring concrete. 7. Infrastructure projects: Steel frame formwork is widely employed in infrastructure projects such as highways, railways, and airports. It enables the construction of sturdy and durable structures capable of withstanding heavy traffic and adverse weather conditions. To sum up, steel frame formwork is a versatile technique for creating a wide range of concrete structures, including high-rise buildings, bridges, industrial buildings, retaining walls, water tanks, tunnels, and infrastructure projects. Its strength, stability, and flexibility make it a preferred choice for numerous construction applications.

- Q: Can steel frame formwork be integrated with other construction systems?

- Yes, steel frame formwork can be integrated with other construction systems. It is a versatile system that can be easily adapted and combined with various construction methods and materials, allowing for efficient and effective construction processes.

- Q: Can steel frame formwork be used in projects with limited formwork storage space?

- Projects with limited formwork storage space can utilize steel frame formwork. This type of formwork is recognized for its versatility and compactness, making it an ideal option. Unlike traditional timber formwork, steel frame formwork is designed to be lightweight and easy to handle, enabling efficient storage and transportation. Moreover, steel frame formwork offers the advantage of reusability, reducing the necessity for additional storage space. Its modular design allows for simple assembly and disassembly, allowing for quick storage when not in use. Additionally, steel frame formwork provides exceptional strength and durability, resulting in a long lifespan and minimizing the need for frequent replacements. Consequently, the amount of formwork material required is reduced, optimizing storage space. In conclusion, steel frame formwork is a suitable choice for projects with limited formwork storage space due to its compactness, reusability, and durability. Its lightweight and modular design facilitate easy handling and storage, maximizing the utilization of available space.

- Q: Are there any limitations to the number of pour cycles for steel frame formwork systems?

- Yes, there are some limitations to the number of pour cycles for steel frame formwork systems. Firstly, the overall durability of the formwork system can be affected by the number of pour cycles. With each pour cycle, the formwork is subjected to the pressure and weight of the concrete, which can cause wear and tear over time. The repeated loading and unloading of the formwork can lead to deformation, bending, or even cracking of the steel frames. Secondly, the quality of the concrete surface can be compromised after multiple pour cycles. Each pour cycle introduces the potential for imperfections such as honeycombing, bug holes, or surface irregularities. These imperfections can accumulate with each subsequent pour cycle, resulting in a less smooth and visually appealing finish. Additionally, the stripping and re-assembly process can become more time-consuming and labor-intensive with each pour cycle. As the formwork system ages, the components may not fit together as tightly or securely, leading to difficulties in removing the formwork or aligning it properly for the next pour. This can slow down the construction process and increase the risk of errors or accidents. Furthermore, the load-bearing capacity of the formwork system may decrease over time. The repeated stress and strain from multiple pour cycles can gradually weaken the steel frames, reducing their ability to support the weight of the concrete. This can compromise the safety of the structure and necessitate more frequent inspections or reinforcement measures. In summary, while steel frame formwork systems offer advantages in terms of strength and reusability, there are limitations to the number of pour cycles they can effectively withstand. Factors such as durability, concrete surface quality, ease of stripping and re-assembly, and load-bearing capacity can all be impacted as the formwork system ages. It is important to consider these limitations and plan accordingly to ensure the successful and safe completion of construction projects.

- Q: How does steel frame formwork contribute to the overall sustainability of a project?

- There are several ways in which steel frame formwork contributes to the overall sustainability of a project. To begin with, steel is an incredibly durable material that can withstand harsh weather conditions and heavy loads. This ensures that the formwork system will last a long time without needing frequent replacements or repairs. As a result, fewer resources are consumed and less waste is generated. Furthermore, steel frame formwork is highly flexible and can easily be adjusted to meet the requirements of different projects. This adaptability allows for efficient use of materials, as the same formwork can be used for multiple concrete structures. This reduces the need for multiple formwork systems and minimizes resource demand and waste generation. Moreover, steel is a recyclable material. At the end of a project's lifecycle, the formwork can be dismantled and the steel can be reused or recycled. This reduces the need for new steel production, which is energy-intensive and emits greenhouse gases. By promoting the circular economy, steel frame formwork helps conserve natural resources and reduces the construction industry's carbon footprint. Additionally, the use of steel frame formwork enables faster construction timelines compared to traditional formwork systems. This reduces the overall project duration, minimizing disruption to the environment and nearby communities. It also results in less energy consumption and lower emissions, as the use of heavy machinery and equipment is reduced. Lastly, steel frame formwork can be designed to maximize energy efficiency in buildings. By incorporating insulation materials within the formwork system, thermal bridging can be minimized, leading to improved energy performance and reduced heating and cooling loads. This results in lower energy consumption and reduced greenhouse gas emissions during the operational phase of a project. In conclusion, steel frame formwork contributes to project sustainability through its durability, adaptability, recyclability, energy efficiency, and reduced construction timelines. By promoting resource conservation, waste reduction, and lower emissions, steel frame formwork plays a vital role in creating more sustainable and environmentally-friendly construction practices.

- Q: What are the key considerations for selecting the appropriate steel frame formwork system for repetitive use?

- When selecting the appropriate steel frame formwork system for repetitive use, there are several key considerations that need to be taken into account. Firstly, the durability and quality of the steel frame formwork system is of utmost importance. Since it will be used repetitively, it needs to withstand the constant wear and tear without compromising its integrity. The steel used should be of high quality and have the necessary strength and toughness to withstand the repetitive loads. The ease of assembly and disassembly is another crucial factor to consider. The formwork system should be designed in such a way that it can be easily assembled and disassembled without requiring excessive time or effort. This will not only save time during construction but also make it more efficient for repetitive use. Additionally, the adjustability and flexibility of the formwork system should be considered. It should be capable of accommodating different sizes and shapes of concrete structures. This adaptability is crucial as it allows for versatility in construction projects and ensures that the formwork system can be reused for various purposes. Furthermore, the safety features of the steel frame formwork system should be thoroughly evaluated. It should have adequate bracing and support to ensure stability during the concrete pouring process. It should also have proper guardrails and safety measures in place to protect workers from potential hazards. The cost-effectiveness of the formwork system is another key consideration. While it is important to select a reliable and durable system, it is equally important to ensure that it offers value for money. Comparing the initial investment with the expected lifespan and number of reuses can help determine the cost-effectiveness of the system. Lastly, the availability of technical support and maintenance services should be considered. It is essential to choose a manufacturer or supplier that provides adequate technical support and maintenance services throughout the lifespan of the formwork system. This ensures that any issues or repairs can be addressed promptly, minimizing downtime and maximizing the system's longevity. By considering these key factors, one can select the appropriate steel frame formwork system that is durable, easy to assemble and disassemble, adjustable, safe, cost-effective, and backed by reliable technical support and maintenance services.

- Q: Can steel frame formwork be used for both commercial and residential construction?

- Certainly! Steel frame formwork is applicable to both commercial and residential construction endeavors. This versatile and durable system is well-suited for a broad spectrum of construction projects. It presents numerous advantages, including strength, stability, and reusability, rendering it suitable for both modest residential dwellings and expansive commercial edifices. The steel frame formwork system can be easily assembled, disassembled, and adjusted to cater to diverse project specifications, thereby presenting a cost-effective solution for various construction applications. Whether the task is erecting residential abodes or commercial establishments such as offices, hospitals, or shopping centers, steel frame formwork offers a dependable and effective approach for fabricating concrete structures.

- Q: Can steel frame formwork be used for both flat and sloped slab construction?

- Indeed, steel frame formwork is applicable for both flat and sloped slab construction endeavors. This particular formwork option offers a resilient and long-lasting solution for establishing the essential mold or framework required for concrete pouring. It possesses the flexibility to effortlessly adapt to various angles and configurations of slabs, thus rendering it suitable for both flat and sloped surfaces. The steel frame formwork system enables meticulous alignment and furnishes a robust support structure, guaranteeing precise and secure concrete pouring for the slab. Furthermore, this formwork can be utilized multiple times, making it a cost-efficient alternative for both flat and sloped slab construction ventures.

- Q: Does steel frame formwork require any specific waterproofing measures?

- Yes, steel frame formwork does require specific waterproofing measures. Since steel is not inherently waterproof, it is important to use appropriate waterproofing materials and techniques to prevent water ingress and potential damage to the formwork. This can include applying waterproof membranes, sealants, or coatings to the steel surfaces, as well as ensuring proper joint sealing and drainage to prevent water accumulation.

- Q: What are the different types of formwork lifting devices used with steel frame formwork?

- Steel frame formwork can be paired with various formwork lifting devices, offering construction workers a multitude of options for effectively and securely maneuvering and placing the formwork throughout the building process. Among the assortment of devices, cranes are frequently employed. They excel at lifting and transporting sizable portions of steel frame formwork, making them ideal for use on extensive construction sites that necessitate heavy lifting. These cranes can be operated either by a skilled crane operator or remotely via a remote control. Forklifts, on the other hand, represent another commonly utilized lifting apparatus in conjunction with steel frame formwork. Their smaller size and enhanced maneuverability render them fitting for deployment on smaller construction sites or areas with space constraints. Forklifts are typically operated by trained forklift operators. Apart from cranes and forklifts, specialized lifting devices tailored specifically for steel frame formwork also exist. Hydraulic jacks, for instance, are employed to elevate and lower individual formwork sections, while lifting clamps securely fasten and raise formwork panels. In summary, the array of formwork lifting devices used alongside steel frame formwork furnishes construction workers with a diverse range of options to safely and efficiently transfer and position the formwork throughout the construction process.

Send your message to us

750 Series Adjustable Steel Frame Formwork with Special hollow steel

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches