various kinds of plastic formworks newly used

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Main Introduction of Plastic Formwork:

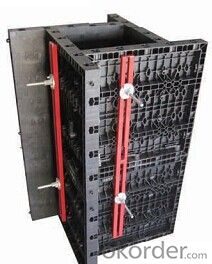

More and more people in the world would like to importPlasticformwork from China since recentyears. Plastic formwork is a new type construction material in the construction industry andpeople could buy good quality at a very good price from Chinese market. In this way, the distributors make more profit and the end users could save more cost. Before you decide to purchase this kind of plastic formwork, you need to know how plastic formwork sprung up and grasped the market.The biggest panel is 120x60cm, weight only 10.5kg, which can be lift and set up by only one person easily, need no crane on the site.

2. The Advantages of Plastic Formwork:

1:easy set up

Different size of panels can be firmly locked by simply turn the special handles to 90 degree. The panels have rib on the back, which makes the

system need not traditional wood blocks and nails. The panels have holes to fit tie rod, guarantee the strength of the whole system.

2:modularity

Modular formwork composed by different size of panels, the main item is 120x60 panel, the size is 120x60cm, which used for the large area of walls

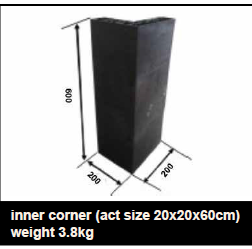

and slabs. There are also small size of panels like 10x60 panel (10x60cm), 20x60 panel (20x60cm), 25x60 panel (25x60cm), inner corner (20x20x60cm) and outer corner (10x5x60cm). Due to the variety of panel size, the system can form almost all size walls120x60 panel (act size 120x60cm) of multiple by 5cm. The material of modular formwork is PC-ABS mixied with special glass fibres which enable panels to hold high pressures.

3:strength

The handles are made by high strength Nilon, each panel locked by at least 4 handls, which makes the whole system strong enough to pour 40cm walls.

4:friendly

The system need not cut and nail due to the variety size, and nearly need no wood, the material can be recycled after broken, will not pollute the enviroment.

5:consequent

Concrete does not stick to plastic, thus the panels need no oil before using, and can be cleaned simply by water. The surface of the wall which built by modular formwork is smooth, can be left without rework.

4. FAQ of Plastic Formwork

1) What can we do for you?

We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in plastic formwork, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

- Q: How does steel frame formwork handle concrete curing in different weather conditions?

- Steel frame formwork is a versatile and durable system used for concrete construction. It is designed to handle concrete curing in various weather conditions. In hot weather, steel frame formwork helps to prevent excessive evaporation of moisture from the concrete surface. The steel frames provide a rigid structure that holds the concrete in place, preventing it from cracking due to rapid drying. Additionally, the steel formwork can be easily insulated, which helps in maintaining the required temperature for proper concrete curing even in extreme heat. In cold weather, steel frame formwork helps to protect the concrete from freezing. The steel frames act as a barrier, shielding the concrete from low temperatures and preventing it from freezing during the curing process. Furthermore, insulating materials can be added to the steel formwork to enhance its thermal efficiency, ensuring that the concrete cures properly even in freezing temperatures. In rainy or humid weather conditions, steel frame formwork is built with watertight seals to prevent water from entering the concrete structure. This is crucial as excess moisture can weaken the concrete and affect its strength. The steel formwork, along with the use of waterproof membranes and sealants, helps to create a protective barrier against water infiltration, allowing the concrete to cure effectively. Overall, steel frame formwork is specifically designed to handle different weather conditions during concrete curing. Its robust construction and ability to withstand extreme temperatures and moisture ensure that the concrete cures properly, resulting in a strong and durable structure.

- Q: Are there any limitations to the number of pour cycles for steel frame formwork systems?

- The number of pour cycles for steel frame formwork systems has certain limitations that should be taken into account. To begin with, the overall durability of the formwork system can be affected by the number of pour cycles. As each pour cycle occurs, the formwork undergoes pressure and weight from the concrete, resulting in wear and tear over time. This repeated loading and unloading of the formwork can cause deformation, bending, or even cracking of the steel frames. Moreover, the quality of the concrete surface may be compromised after multiple pour cycles. Each pour cycle introduces the possibility of imperfections such as honeycombing, bug holes, or surface irregularities. These imperfections can accumulate with subsequent pour cycles, leading to a less smooth and visually appealing finish. Additionally, the process of stripping and re-assembly can become more time-consuming and labor-intensive as pour cycles increase. As the formwork system ages, its components may not fit together as tightly or securely, making it difficult to remove or align the formwork properly for the next pour. Consequently, this can slow down the construction process and increase the risk of errors or accidents. Furthermore, the load-bearing capacity of the formwork system may decrease over time. The repeated stress and strain from multiple pour cycles can gradually weaken the steel frames, reducing their ability to support the weight of the concrete. As a result, the safety of the structure may be compromised, necessitating more frequent inspections or reinforcement measures. In conclusion, while steel frame formwork systems offer advantages in terms of strength and reusability, it is important to recognize the limitations regarding the number of pour cycles they can effectively withstand. Considerations such as durability, concrete surface quality, ease of stripping and re-assembly, and load-bearing capacity can all be influenced as the formwork system ages. Therefore, careful planning is necessary to ensure the successful and safe completion of construction projects.

- Q: How does steel frame formwork affect the overall safety of workers during concrete pouring and curing?

- Steel frame formwork can significantly enhance the overall safety of workers during concrete pouring and curing. Its sturdy and robust construction provides stability and support to the concrete structure, reducing the risk of collapse or accidents. Steel frame formwork also allows for precise and controlled concrete placement, preventing any potential hazards caused by uneven pouring. Additionally, its durability ensures a secure working environment, minimizing the chances of accidents and injuries associated with formwork failure. Overall, the use of steel frame formwork enhances worker safety by providing a reliable and stable structure during concrete pouring and curing processes.

- Q: What are the key considerations for selecting the appropriate steel frame formwork contractor?

- When selecting the appropriate steel frame formwork contractor, there are several key considerations that should be taken into account. These considerations include the contractor's experience and expertise, their track record and reputation, their safety record, their pricing and value for money, and their ability to meet project deadlines. Firstly, it is important to assess the contractor's experience and expertise in steel frame formwork. This can be done by reviewing their portfolio of past projects, as well as their qualifications and certifications. A contractor with extensive experience in steel frame formwork will have the necessary skills and knowledge to handle the complexities of the job efficiently and effectively. Secondly, the contractor's track record and reputation should be carefully evaluated. This can be done by checking references and reading reviews or testimonials from previous clients. A contractor with a solid track record and positive reputation is more likely to deliver high-quality work and provide excellent customer service. Safety is another crucial consideration when selecting a steel frame formwork contractor. It is important to ensure that the contractor has a strong safety record and follows all necessary safety protocols. This can be determined by reviewing their safety certifications and asking about their safety procedures and training programs. Pricing and value for money are also important considerations. While it is natural to want to find the most cost-effective option, it is equally important to consider the quality of work and materials provided by the contractor. It is recommended to obtain multiple quotes and compare them, taking into account the contractor's experience, reputation, and the scope of the project. Finally, the contractor's ability to meet project deadlines should be considered. It is important to ensure that the contractor has the capacity and resources to complete the project within the specified timeframe. This can be determined by discussing project timelines and deadlines with the contractor and assessing their project management capabilities. In conclusion, selecting the appropriate steel frame formwork contractor requires careful consideration of their experience, track record, safety record, pricing, and ability to meet project deadlines. By evaluating these key factors, you can make an informed decision and choose a contractor that will deliver high-quality work and meet your project requirements.

- Q: Can steel frame formwork be used for both temporary and permanent construction?

- Absolutely, steel frame formwork can be utilized for both temporary and permanent construction purposes. This adaptable and sturdy system boasts a multitude of benefits for construction projects. It guarantees remarkable strength, durability, and stability, rendering it highly suitable for enduring utilization in permanent structures. Moreover, the disassembling and reassembling process of steel frame formwork is effortless, making it the perfect choice for temporary structures that require relocation or dismantling within a specific timeframe. Its versatility and adaptability have made it a favored option for diverse construction applications, be it temporary or permanent.

- Q: Can steel frame formwork be used for both horizontal and vertical concrete structures?

- Yes, steel frame formwork can be used for both horizontal and vertical concrete structures. Steel frame formwork is a versatile and durable system that can be easily assembled and disassembled, making it suitable for various construction projects. It provides a strong and rigid support for the concrete during pouring and curing, ensuring proper alignment and stability for both horizontal slabs and vertical walls. Additionally, steel frame formwork allows for precise adjustment and customization to accommodate different shapes and sizes of structures. Its robust construction and ability to withstand high pressure and load make it an ideal choice for both horizontal and vertical concrete structures.

- Q: Are there any specific requirements for the concrete mix used with steel frame formwork?

- Yes, there are specific requirements for the concrete mix used with steel frame formwork. The concrete mix for steel frame formwork should have certain properties to ensure the structural integrity and strength of the construction. Firstly, the concrete mix should have a high compressive strength. This is necessary to withstand the pressure and weight of the steel frame and other loads that will be imposed on the structure. The specific compressive strength requirement will depend on the design and intended use of the structure. Secondly, the concrete mix should have good workability. It should be easy to pour, compact, and shape within the steel frame formwork. This is important for achieving the desired shape and dimensions of the structure. The workability of the concrete can be improved by using appropriate admixtures such as plasticizers or superplasticizers. Thirdly, the concrete mix should have low bleeding and segregation tendencies. Bleeding refers to the separation of water from the mix, while segregation refers to the separation of coarse aggregates from the mix. These issues can lead to a non-uniform distribution of materials and affect the overall strength and durability of the structure. Proper mix design and control can minimize these problems. Lastly, the concrete mix should have adequate durability. It should be resistant to environmental factors such as freeze-thaw cycles, chemical attacks, and abrasion. This is important for the long-term performance and lifespan of the structure. The mix design should incorporate appropriate cementitious materials, aggregates, and admixtures to enhance the durability of the concrete. In summary, the concrete mix used with steel frame formwork should have high compressive strength, good workability, low bleeding and segregation tendencies, and adequate durability. These requirements ensure the structural integrity and long-term performance of the construction.

- Q: What are the different types of finishes that can be achieved with steel frame formwork?

- Steel frame formwork enables the achievement of various finishes on concrete surfaces. These finishes include: 1. Sleek Finish: The most common finish attained with steel frame formwork, it yields a flawless and uniform surface. This finish is frequently utilized for architectural and decorative purposes, where a high-quality appearance is desired. 2. Textured Finish: Steel frame formwork allows for the creation of a textured finish on concrete surfaces. This type of finish adds depth and intrigue to the surface and can be achieved through the use of diverse form liners, special coatings, or treatments applied to the steel formwork. 3. Exposed Aggregate Finish: Steel frame formwork makes it possible to achieve an exposed aggregate finish on concrete surfaces. This finish involves removing the top layer of concrete to reveal the aggregate particles, resulting in a decorative and textured surface. The design of the steel formwork can accommodate this process, providing precise control over the depth and placement of the exposed aggregate. 4. Stamped Finish: Steel frame formwork also enables the attainment of a stamped finish. This technique involves imprinting a pattern or design onto the concrete surface before it sets, creating a textured or patterned effect. The steel formwork can be customized to accommodate different stamping patterns, offering a wide range of design possibilities. 5. Polished Finish: Steel frame formwork can be employed to achieve a polished finish on concrete surfaces. This involves grinding and polishing the surface to achieve a smooth and reflective shine. The design of the steel formwork supports the polishing process, ensuring a flat and even surface suitable for achieving the desired level of shine. In summary, steel frame formwork provides a versatile and adaptable solution for achieving various finishes on concrete surfaces. Whether it is a sleek, textured, exposed aggregate, stamped, or polished finish, the steel formwork can be tailored to meet the specific requirements and design preferences of a project.

- Q: How does steel frame formwork affect the overall structural integrity of a building?

- Steel frame formwork can have a significant impact on the overall structural integrity of a building. Firstly, steel frame formwork provides a strong and rigid support system for the concrete during construction. This ensures that the concrete is poured and cured properly, leading to a more durable and robust structure. The use of steel frame formwork also allows for precise and accurate placement of the concrete, which is essential for maintaining the structural integrity of the building. The formwork system ensures that the concrete is poured in the correct location and shape, preventing any potential weaknesses or inconsistencies in the structure. Furthermore, steel frame formwork provides excellent stability and resistance against external forces such as wind, earthquakes, and other loads. The steel framework acts as a reinforcement, enhancing the overall strength and stability of the building. This is particularly important in areas prone to seismic activities or extreme weather conditions. Moreover, steel frame formwork is highly resistant to corrosion and deterioration, making it a long-lasting and reliable choice for construction. This durability ensures that the formwork system does not compromise the structural integrity of the building over time. Overall, the use of steel frame formwork greatly enhances the structural integrity of a building. It provides a strong support system, precise placement of concrete, stability against external forces, and long-term durability. Architects and engineers often prefer steel frame formwork due to its ability to ensure a safe and sturdy structure, making it an essential component in the construction process.

- Q: What are the different types of coatings or surface treatments applied to steel frame formwork?

- There are several different types of coatings or surface treatments that can be applied to steel frame formwork to enhance its performance and durability. 1. Galvanized Coating: Galvanization involves applying a layer of zinc to the steel surface through a process called hot-dip galvanizing. This coating provides excellent corrosion resistance, protecting the formwork from rust and other environmental damages. 2. Powder Coating: Powder coating is a popular method that involves applying a dry powder to the steel surface and then heating it to form a protective layer. This coating provides a durable finish, protecting the formwork from scratches, chemicals, and UV rays. 3. Epoxy Coating: Epoxy coatings are typically used in aggressive environments where corrosion resistance is crucial. These coatings are applied in multiple layers and provide excellent chemical resistance, protecting the formwork from acids, alkalis, and other corrosive substances. 4. Paint Coating: Paint coatings are a common choice for steel formwork. They provide a decorative finish while also offering some level of corrosion protection. However, paint coatings may require regular maintenance and may not be as durable as other types of coatings. 5. Zinc-Rich Primer: Zinc-rich primers are applied as a base coat before the final coating to provide additional corrosion protection. These primers contain high levels of zinc, which acts as a sacrificial anode and helps to prevent the steel from corroding. 6. Anodized Coating: Anodizing is a process mainly used for aluminum formwork, but it can also be applied to steel. It involves creating a layer of aluminum oxide on the surface through an electrochemical process. This coating provides enhanced corrosion resistance and can also improve the formwork's appearance. Overall, the choice of coating or surface treatment for steel frame formwork depends on the specific application, environmental conditions, and desired level of protection. It is essential to consider factors such as corrosion resistance, durability, aesthetics, and maintenance requirements when selecting the appropriate coating.

Send your message to us

various kinds of plastic formworks newly used

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords