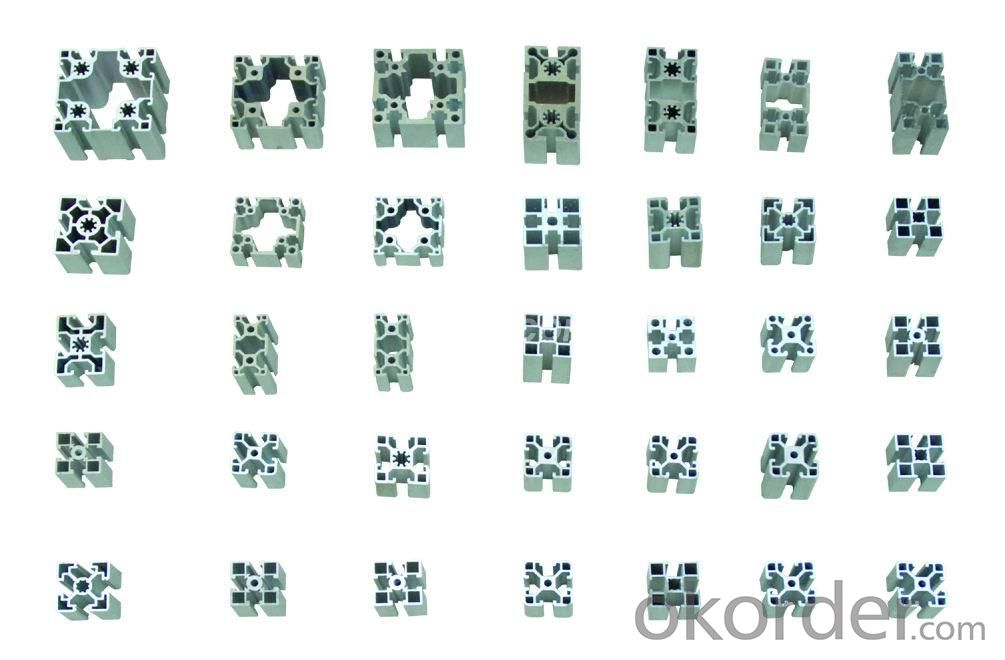

T Slot Aluminum Extrusion Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Aluminium is a relatively soft, durable, lightweight,ductile and malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible light and an excellent reflector(as much as 98%) of medium and far infrared radiation. The yield strengthof pure aluminium is 7–11 MPa, while aluminium alloys have yield strengthsranging from 200 MPa to 600 MPa. Aluminium has about one-third the density and stiffness of steel.It is easily machined, cast, drawnand extruded.

Advantage:

• Smooth surface

• High manufacturing accuracy

• High strength of extension and yield

• Well packaged

• No marks, no scratch, no excessive oil

Alu Profile:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Guangzhou/Shenzhen port

4. Delivery time?

15-20 days after client’s deposit

- Q: This question asks for a list of various uses of aluminum profiles within the construction industry.

- <p>Aluminum profiles have a wide range of applications in the construction industry due to their strength, durability, and lightweight properties. They are used in window and door frames for their resistance to corrosion and ease of maintenance. They are also employed in curtain walls, which are the outer coverings of buildings, providing both aesthetic appeal and structural integrity. Aluminum profiles are utilized in the construction of scaffolding for their high strength-to-weight ratio, ensuring safety and stability. Additionally, they are used in the manufacturing of modular buildings and prefabricated structures due to their ease of assembly and disassembly. Other applications include roofing systems, flooring structures, and as support beams in various construction projects.</p>

- Q: Can someone give me a direction? Thank you

- Look where you are and where you are. There are various directions for development, such as bags and so on, bathroom..

- Q: Is it possible to utilize recycled aluminum products as an alternative to new ones to decrease environmental impact and save costs?

- <p>Yes, using recycled aluminum products is an effective way to reduce environmental impact and cost. Recycling aluminum requires significantly less energy compared to producing new aluminum from raw materials, which reduces greenhouse gas emissions. Additionally, recycled aluminum retains the same properties as new aluminum, making it a viable alternative for many applications. This practice not only conserves resources but also lowers production costs, making it a sustainable choice for both the environment and your budget.</p>

- Q: What are the advantages of using aluminum profiles in window and door frames?

- There are several advantages of using aluminum profiles in window and door frames. Firstly, aluminum is a lightweight material, making it easier to handle and install. Additionally, it is highly durable and resistant to corrosion, ensuring long-lasting performance. Aluminum profiles also offer excellent thermal insulation, helping to reduce energy consumption and maintain comfortable indoor temperatures. Moreover, aluminum is highly versatile, allowing for various design options and customization. Finally, aluminum is an environmentally friendly choice, as it is recyclable and has a low carbon footprint.

- Q: Are aluminum profiles suitable for partition walls?

- Yes, aluminum profiles are suitable for partition walls. They are lightweight, durable, and offer excellent structural support. Additionally, aluminum profiles are easy to install, maintain, and can be customized to fit different design requirements. They also provide good thermal and sound insulation properties, making them a popular choice for partition walls in various settings such as offices, homes, and commercial spaces.

- Q: What are the standard dimensions and sizes of aluminum profiles?

- The standard dimensions and sizes of aluminum profiles can vary depending on the specific application and industry. However, there are some common dimensions and sizes that are widely used in various industries. In general, aluminum profiles come in various shapes such as angles, channels, tubes, and bars. The dimensions of these profiles typically range from small to large, with sizes measured in terms of width, height, and thickness. For example, aluminum angle profiles commonly have dimensions ranging from 1/2 inch to 8 inches in width and height, with thicknesses ranging from 1/16 inch to 1/2 inch. Aluminum channel profiles can have widths ranging from 1/2 inch to 12 inches, heights ranging from 1/2 inch to 3 inches, and thicknesses ranging from 1/16 inch to 1/4 inch. Aluminum tube profiles often come in various outer diameters, ranging from 1/8 inch to 6 inches, with wall thicknesses ranging from 1/32 inch to 1/4 inch. Aluminum bar profiles typically have widths ranging from 1/8 inch to 12 inches, heights ranging from 1/8 inch to 4 inches, and thicknesses ranging from 1/16 inch to 1/2 inch. It is important to note that these dimensions and sizes are just a general guideline, and specific applications may require custom dimensions or sizes. Additionally, different countries or regions may have their own standards and variations in aluminum profile dimensions and sizes. Therefore, it is always advisable to consult with manufacturers or suppliers to determine the specific dimensions and sizes that meet your requirements.

- Q: Aluminum profile spraying process

- Pretreatment -- drying, removing moisture -- spraying -- Inspection -- baking -- Inspection -- finished.1, construction requirements, general powder spraying construction requirements:(1) in order to give full play to and extend the service life of the coating, the surface of the coating is strictly treated by surface pretreatment first(2) when spraying, the coating must be completely ground to increase the spraying efficiency of the powder coating(3) to be coated with larger surface defects, it should be coated with conductive putty to ensure the smooth and smooth coating(4) after the spraying, the objects and articles should be heated, cured and solidified. The technical indexes of the powder products should be adopted, but the curing temperature and time should be guaranteed so as to avoid the quality failures caused by solidification(5) check immediately after spraying, if found defects should be timely treatment, if after curing defects are found, the only local small range without affecting, the coated surface decoration, can use the same color powder and acetone diluted to repair, if the scope is large and affects the surface quality, use sandpaper after again. Or use the paint remover to remove the coating, re Suo powder.(6) the recovered powder must be screened and removed, and then mixed with the new powder at a certain proportion(7) the powder supply barrel, the powder spraying room and the recycling system should avoid contamination by other colors. Therefore, each color change must be cleaned

- Q: Can aluminum profiles be used in agricultural applications?

- Indeed, aluminum profiles find utility in agricultural applications. The strength, durability, and corrosion resistance of aluminum render it a perfect material for diverse agricultural structures and equipment. One can utilize it for constructing greenhouse frames, irrigation systems, grain storage bins, livestock housing, and beyond. Moreover, aluminum profiles possess a lightweight nature, simplifying their handling and installation procedures. Furthermore, their exceptional thermal conductivity facilitates efficient temperature regulation within agricultural settings. On the whole, aluminum profiles present a multitude of advantages and are progressively gaining popularity in the agricultural sector.

- Q: Is it possible to recycle aluminum profiles and incorporate them into new construction projects?

- <p>Yes, aluminum profiles can be recycled and reused in new building projects. Aluminum is highly recyclable, and the recycling process is energy-efficient, requiring only 5% of the energy needed to produce new aluminum. Recycled aluminum maintains its properties, making it suitable for various applications in construction. This practice not only conserves resources but also reduces waste and environmental impact.</p>

- Q: Can aluminum profiles be used for retail displays?

- Yes, aluminum profiles can be used for retail displays. Aluminum profiles are versatile and can be customized to meet various design requirements. They are lightweight yet strong, making them ideal for creating durable and long-lasting retail displays. Additionally, aluminum profiles can be easily shaped, cut, and assembled to create unique and eye-catching displays. They can also be powder-coated or anodized to achieve different colors and finishes, enhancing the aesthetics of the retail space. Furthermore, aluminum profiles can be easily integrated with other materials such as glass, acrylic, or wood to create a multi-material display. Overall, the flexibility, durability, and aesthetic appeal of aluminum profiles make them a great choice for retail displays.

Send your message to us

T Slot Aluminum Extrusion Profiles

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords