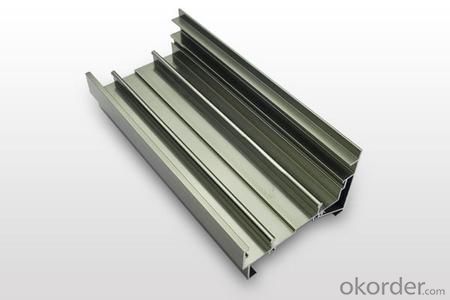

Aluminum Threshold Profiles for Any Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

We provide a full range of precision aluminum strip for almost any application. We produce aluminum strip in a wide variety of alloys, including clad composites. Our aluminum strip can be produced in standard dimensions or custom made to your special requirements. We produce both imperial and metric units. We manufacture in compliance with the main international specifications, and tighter tolerances or custom tempers are available upon request. We offer various surface conditions, custom finishes (painting, anodizing, embossing), special processing, and multiple packaging options to meet our customer's unique requirements. The following is a summary of our capabilities.

Manufactured in compliance with the main international specifications and standards, including: Aluminum Association, ASTM, EN, and DIN.

We can also manufacture in compliance with other international standards including:ASME, SAE, AMS, AWS, FED, MIL, QQ, ISO, BS, AFNOR, JIS and GOST.

Manufactured in compliance with the main international specifications and standards.

Tighter tolerances are available upon request.

Aluminium (or aluminum; see spelling differences) is a chemical element in the boron group with symbol Al and atomic number 13. It is a silvery white, soft, ductile metal. Aluminium is the third most abundant element (after oxygen and silicon), and the most abundant metal in the Earth's crust. It makes up about 8% by weight of the Earth's solid surface. Aluminium metal is so chemically reactive that native specimens are rare and limited to extreme reducing environments. Instead, it is found combined in over 270 different minerals.The chief ore of aluminium is bauxite.

Aluminium is remarkable for the metal's low density and for its ability to resist corrosion due to the phenomenon of passivation. Structural components made from aluminium and its alloys are vital to the aerospace industry and are important in other areas of transportation and structural materials. The most useful compounds of aluminium, at least on a weight basis, are the oxides and sulfates.

Despite its prevalence in the environment, no known form of life uses aluminium salts metabolically. In keeping with its pervasiveness, aluminium is well tolerated by plants and animals. Owing to their prevalence, potential beneficial (or otherwise) biological roles of aluminium compounds are of continuing interest.

- Q: How do aluminum profiles contribute to LEED certification?

- LEED certification can be achieved through various means with the use of aluminum profiles. Firstly, aluminum is a sustainable material that can be easily recycled without compromising its quality. Incorporating aluminum profiles in construction projects helps reduce the demand for new raw materials, conserves energy, and minimizes greenhouse gas emissions. This aligns with LEED's objective of minimizing the environmental impact of buildings. Furthermore, aluminum profiles possess the qualities of being lightweight and durable, making transportation and installation efficient. This aspect contributes to earning LEED points in the Sustainable Sites category, which emphasizes the use of materials and techniques that have minimal impact on ecosystems and reduce pollution during construction. Moreover, aluminum profiles can enhance energy efficiency in buildings. By incorporating features like thermal breaks and insulation, aluminum profiles prevent heat transfer and reduce energy consumption for heating or cooling. This aspect contributes to earning LEED points in the Energy and Atmosphere category, which advocates for the use of energy-efficient systems and materials. Additionally, aluminum profiles are corrosion-resistant and require minimal maintenance throughout their lifespan. This durability contributes to earning LEED points in the Materials and Resources category, which encourages the use of long-lasting, low-maintenance materials to minimize waste and the need for replacement. In conclusion, aluminum profiles play a vital role in achieving LEED certification as they promote sustainability, reduce environmental impacts, improve energy efficiency, and enhance building durability. By considering the incorporation of aluminum profiles in construction projects, architects and builders can earn LEED credits and contribute to a more sustainable future.

- Q: This question asks if aluminum profiles can be utilized for constructing interior partitions or ceilings.

- <p>Yes, aluminum profiles are commonly used for interior partitions and ceilings due to their strength, durability, and lightweight properties. They offer design flexibility, are easy to install, and can be used in conjunction with various materials like glass or fabric. Additionally, aluminum profiles are resistant to corrosion and require minimal maintenance, making them a popular choice for both residential and commercial applications.</p>

- Q: Are aluminum profiles suitable for greenhouse structures?

- Yes, aluminum profiles are highly suitable for greenhouse structures. They are lightweight, durable, and resistant to rust and corrosion, making them ideal for outdoor environments. Additionally, aluminum profiles offer excellent strength and flexibility, allowing for easy customization and assembly of greenhouse structures.

- Q: What's the price of aluminum alloy die castings and aluminum profiles?

- In fact, the price is different, mainly depends on quality

- Q: What are the different surface texturing options for aluminum profiles?

- Some of the different surface texturing options for aluminum profiles include anodizing, powder coating, brushing, polishing, and sandblasting. These techniques can be used to create different textures and finishes on the surface of the aluminum profiles, enhancing their appearance and providing additional protection against corrosion and wear.

- Q: How strong are aluminum profiles?

- Known for their strength and durability, aluminum profiles are highly regarded in various applications. With a high strength-to-weight ratio, they prove to be excellent choices. The strength of aluminum profiles may vary based on factors like the alloy used, tempering process, and profile design. Typically, they can withstand substantial loads and pressures, making them suitable for a wide array of structural and industrial purposes. Moreover, their exceptional resistance to corrosion further bolsters their strength and longevity. All in all, aluminum profiles are widely recognized as robust and dependable materials, delivering outstanding performance across different applications.

- Q: This question asks about the various standards and specifications that govern the manufacturing and quality of aluminum profiles.

- <p>Aluminum profiles are governed by a variety of standards and specifications that ensure quality and consistency. These include international standards such as ISO 7599, which specifies tolerances for aluminum profiles, and ASTM B221, which covers aluminum and aluminum-alloy extruded bars, rods, and profiles. National standards like the European EN 573 or the Chinese GB/T 6892 also provide guidelines for aluminum profiles. Specifications cover dimensions, mechanical properties, surface finishes, and tolerances. Each standard may have specific requirements for different types of profiles, such as those used in construction, automotive, or aerospace industries. Compliance with these standards is crucial for ensuring the safety, performance, and reliability of aluminum profiles in various applications.</p>

- Q: Can aluminum profiles be used for exhibition stands or booths?

- Exhibition stands or booths can indeed utilize aluminum profiles. The lightweight and robust characteristics of aluminum make it a favored option for constructing such structures. Its ability to provide structural stability, along with the convenience of transportation and assembly, further adds to its appeal. Aluminum profiles are easily customizable, allowing for their seamless integration into diverse designs and configurations, thereby catering to various exhibition needs. Moreover, aluminum's recyclability aligns with the sustainable practices frequently sought after in the exhibition and event industries. In summary, aluminum profiles present a cost-effective and pragmatic choice for the creation of exhibition stands or booths.

- Q: Can aluminum profiles be used for electrical applications?

- Yes, aluminum profiles can be used for electrical applications. Aluminum is a highly conductive material, making it suitable for electrical conductivity. Aluminum profiles are commonly used in electrical applications such as power distribution systems, wiring conduits, and bus bars. They provide a lightweight and cost-effective solution for electrical installations. Additionally, aluminum profiles offer good thermal conductivity, which helps in dissipating heat generated by electrical components. However, it is important to consider the specific requirements of the electrical application and ensure that the aluminum profiles meet the necessary electrical safety standards and regulations.

- Q: This question asks about the various methods employed in the production of aluminum profiles, which are long, extruded shapes made from aluminum.

- <p>Aluminum profiles are manufactured using several processes, primarily extrusion, which involves forcing aluminum through a die to create specific shapes. Other processes include casting, where aluminum is poured into molds, and rolling, used to create flat sheets or plates. Machining processes like cutting, drilling, and milling are also used for further shaping and finishing. Additionally, aluminum profiles can be fabricated through bending, which shapes the material into curves or angles, and welding, which joins pieces together. Surface treatments like anodizing, painting, or powder coating are also applied to enhance appearance and durability.</p>

Send your message to us

Aluminum Threshold Profiles for Any Application

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords