Extruded Aluminum Structural Profiles AA3XXX

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Aluminum Profiles AA3xxx

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

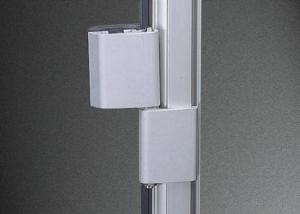

2 Usage/Applications of Aluminum Profiles AA3xxx

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

3 Packaging & Delivery of Aluminum Profiles AA3xxx

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of Aluminum Profiles AA3xxx

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q: Are there any materials for aluminum profiles?

- Yes, aluminum, silicon, aluminum, magnesium and so on

- Q: How do aluminum profiles compare to plastic profiles?

- Aluminum profiles generally offer greater strength, durability, and stability compared to plastic profiles. They can withstand higher loads and have higher resistance to heat, chemicals, and UV radiation. Additionally, aluminum profiles provide more design flexibility, as they can be easily machined, welded, and anodized to achieve desired shapes and finishes. However, plastic profiles are often more cost-effective and lighter in weight, making them suitable for certain applications where strength and rigidity are not critical. Ultimately, the choice between aluminum and plastic profiles depends on the specific requirements and constraints of the project.

- Q: Are aluminum profiles fire-resistant?

- Aluminum profiles are generally considered to be fire-resistant. Aluminum is a non-combustible material that does not catch fire or support combustion. It has a high melting point of around 660 degrees Celsius, which is significantly higher than typical fire temperatures. However, it is important to note that while aluminum itself is fire-resistant, the accessories or components used with aluminum profiles, such as gaskets or seals, may not be. These accessories may have different fire ratings and could affect the overall fire resistance of the assembly. In certain applications, aluminum profiles can be further enhanced with fire-resistant coatings or treatments to improve their fire performance. These coatings can provide additional protection and increase the fire resistance of the profiles. It is always advisable to consult the manufacturer or supplier of the specific aluminum profile to understand its fire-resistant properties and any additional measures that can be taken to ensure fire safety in a particular application.

- Q: Can aluminum profiles be used in the production of laboratory equipment?

- Yes, aluminum profiles can be used in the production of laboratory equipment. Aluminum is a versatile and widely used material in various industries, including laboratory equipment manufacturing. Aluminum profiles offer several advantages for laboratory equipment production. Firstly, aluminum is lightweight yet strong, making it ideal for constructing equipment that needs to be portable or moved frequently within the laboratory. Its lightweight nature also reduces the strain on laboratory personnel when handling and transporting the equipment. Secondly, aluminum profiles can be easily shaped and molded into various forms and sizes, allowing for the customization of laboratory equipment to meet specific requirements. This flexibility in design enables the production of equipment with complex shapes and structures, ensuring optimal functionality and efficiency. Additionally, aluminum is corrosion-resistant, which is crucial in laboratory settings where exposure to chemicals and liquids is common. This property helps to extend the lifespan of the equipment and ensures it remains in good condition even after prolonged use. Furthermore, aluminum profiles can be anodized or coated to provide additional protection against wear, scratches, and other types of damage. This makes the equipment more durable and easier to clean, maintaining the required hygiene standards in laboratories. Lastly, aluminum is a highly conductive material, making it suitable for applications that require heat transfer or electrical conductivity. This property is advantageous for laboratory equipment such as heating plates, heat sinks, or electrical circuit components. In conclusion, aluminum profiles can indeed be used in the production of laboratory equipment. Their lightweight, malleable, corrosion-resistant, and conductive properties make them a suitable choice for manufacturing various types of laboratory equipment, ensuring durability, functionality, and ease of use.

- Q: This question asks for an overview of the various types of fasteners that can be used in conjunction with aluminum profiles.

- <p>Aluminum profiles are commonly used in construction and manufacturing, and they require fasteners for assembly. The different types of fasteners include: 1. T-nuts and T-bolts: These are used for creating strong connections within the profile. 2. Clamping blocks: These are used to secure profiles together without the need for drilling. 3. Corner brackets: These are used to create 90-degree connections between profiles. 4. Angle brackets: Similar to corner brackets but for creating angled connections. 5. End caps: These are used to cover the ends of profiles for a finished look. 6. Dowels: These are used for aligning and joining profiles together. 7. Screws and bolts: These are used for securing components to the profiles. Each type of fastener serves a specific purpose and is chosen based on the particular application and design requirements.</p>

- Q: Does aluminum alloy profile conduct electricity?

- Aluminum conducts well, and aluminium alloys must also be electrically conductive. But aluminum alloys contain impurities such as silicon and magnesium

- Q: What are the different surface protection methods for aluminum profiles?

- Aluminum profiles have various options for surface protection, each providing unique benefits and safeguarding against different environmental factors. Anodizing, powder coating, and liquid coating are among the most commonly used methods. Anodizing is favored for aluminum profiles due to its ability to offer exceptional corrosion resistance and improve the metal's appearance. This technique involves immersing the aluminum profile in an electrolyte solution and applying an electric current to generate an oxide layer on the surface. Anodizing can be done in different colors, allowing for personalization and visual appeal. Powder coating is another extensively employed approach for safeguarding aluminum profiles. During this process, a dry powder is electrostatically applied to the metal's surface and then cured in an oven. The powder melts and forms a durable protective layer, providing resistance against scratches, UV rays, and chemicals. Powder coating is available in a wide array of colors and finishes, offering both protection and aesthetic choices. Liquid coating, such as liquid paint or lacquer, can also be utilized to shield aluminum profiles from corrosion and other environmental elements. Liquid coatings offer versatility in terms of color and finishes, enabling customization and meeting specific design requirements. However, compared to anodizing or powder coating, liquid coatings may be less long-lasting and require more maintenance over time. Furthermore, mechanical finishing techniques like brushing or polishing can be employed to protect aluminum profiles. These methods assist in eliminating imperfections and creating a smooth and visually appealing surface. To summarize, the range of surface protection methods for aluminum profiles includes anodizing, powder coating, liquid coating, and mechanical finishing techniques. Each method presents distinct advantages in terms of corrosion resistance, durability, aesthetics, and customization options. The choice of surface protection method ultimately depends on the specific requirements, budget, and desired appearance of the aluminum profiles.

- Q: Can aluminum profiles be used in electrical enclosure manufacturing?

- Yes, aluminum profiles can be used in electrical enclosure manufacturing. Aluminum is a versatile and lightweight material that offers excellent electrical conductivity, heat dissipation, and corrosion resistance. It can be easily shaped into different profiles to suit specific enclosure designs and can provide adequate protection for electrical components.

- Q: What is the nitriding process of aluminum extrusion die?

- The principle of nitridation:Gas nitrocarburizing, that is gas nitrocarburizing, refers to low temperature nitrocarburizing based on gas nitriding and carburizing. Commonly used media have 50% ammonia, +50% endothermic gas (Nitemper method); 35%-50% ammonia, +50-60% exothermic gas (Nitroc method) and ammonia through the drip ethanol or formamide and so on. In soft nitriding, because of the high solubility of carbon atoms in the epsilon phase, the soft nitrided surface is a common compound of carbon and nitrogen, which is good in toughness and wear resistant.In the process of gas nitrocarburizing, due to the extremely low solubility of carbon atoms, it quickly reaches saturation state and precipitates many super micro cementite points. These cementite particles, as the core of the crystallization of nitrides, contribute to the formation of nitrides. When the surface nitrogen concentration reaches a certain level, the epsilon phase is formed, while the carbon solubility of the epsilon phase is very high, which in turn accelerates the dissolution of carbon.After gas nitrocarburizing, its structure is composed of epsilon phase, gamma phase and nitrogen containing cementite Fe3 (C, N), carbon will reduce the diffusion rate of nitrogen, so the thermal stress and the stress of the tissue are hard, the nitriding is large and the layer is thinner. But at the same time, because the soft nitride layer does not exist. Therefore, the nitride layer, better toughness than hard nitriding

- Q: What specific coatings or treatments are necessary for aluminum profiles to be used outdoors?

- <p>For outdoor use of aluminum profiles, special coatings or treatments are often required to protect against weathering, corrosion, and UV damage. Anodizing is a common process that increases the durability and resistance of aluminum. Powder coating is another method used for additional protection and to provide a wide range of colors. Some profiles may also be treated with a clear coat to maintain the natural look of aluminum while still offering protection. It's important to select the appropriate treatment based on the specific environmental conditions and aesthetic requirements of the application.</p>

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Extruded Aluminum Structural Profiles AA3XXX

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords