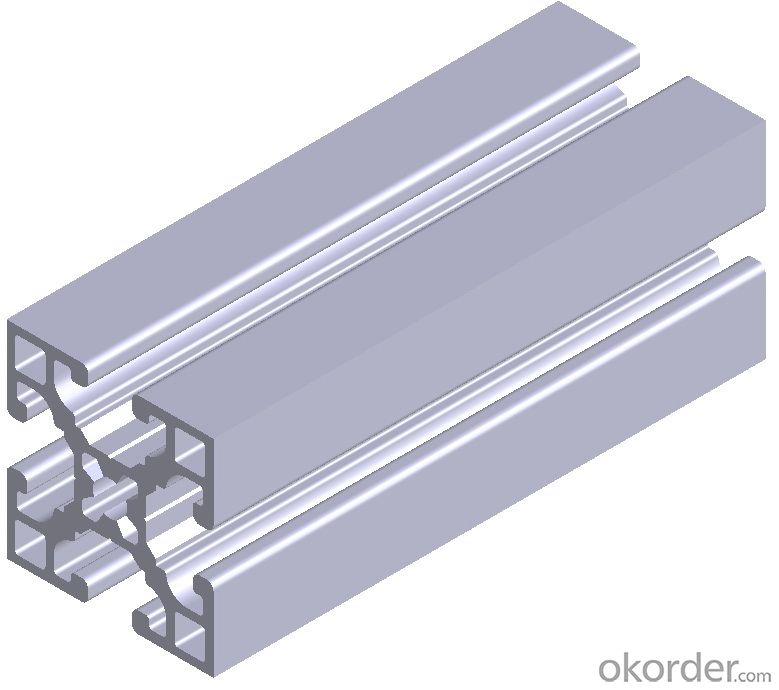

Structural Aluminum Extrusion Profiles - Aluminium S-Profile for Building Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Structure of Aluminium S-profile for Building Constructions Description:

Coated aluminum coil/sheet are of a wide range of colors, which gives wonderful appearance no matter in residential and commercial constructions of great exhibition centers.

The coated aluminum coil/sheet have been widely used in the fields of construction and decoration( garage doors, ceiling etc.), electronic appliances, lighting decoration, air-condition air pipes, sandwich panels and drainages etc.

Main Features of the Aluminium S-profile for Building Constructions:

1) High flexibility

2) Impact resistance

3) Excellent weather-proof durability

4) Anti-ultraviolet

5) High erosion resist

Images of theAluminium S-profile for Building Constructions:

Aluminium S-profile for Building Constructions Specification:

Alloy | A1100,A3003,A1050,A8011 etc |

Temper | H16,H18,H24 |

Thickness | From 0.024mm to 1.2mm |

Width | Standard width:1240mm |

Special width:1300mm,1520mm,1570mm,1595mm | |

Diameter | Standard dia:1200mm |

Interior dia:150mm,405mm,505mm | |

Weight | 2.5 T/coil,3.0 T/coil |

Coating | PE, PVDF, AC |

Surface | Embossed, mill finish, coated |

Color | AS to code RAL |

Gloss | 10-90%(EN ISO-2813:1994) |

Coating Thickness | PE: more than 18 micron |

PVDF: more than 25 micron | |

Coating Hardness (pencil resistance) | More than 2h |

Coating adhesion | 5J(EN ISO-2409:1994) |

Impact Resistance | No peeling or cracking(50 kg/cm,ASTMD-2794:1993) |

Flexibility (T-bend) | 2T |

MEK resistance | More than 100 |

FAQ:

a.What is monthly capacity

---CNBM is one stated own company and our monthly capacity is about 2000tons.

b. Now which countries do you export your goods?

---Now we export to South East Asia,Africa, North America,South America ect.

- Q: How do aluminum profiles perform in terms of heat resistance?

- Aluminum profiles exhibit good heat resistance properties. Aluminum has a relatively high melting point of 660.3°C (1220.5°F) and a low thermal expansion coefficient, which enables them to withstand high temperatures without significant deformation or structural damage. This makes aluminum profiles suitable for various applications requiring heat resistance, such as heat sinks, automotive components, and industrial equipment. Additionally, aluminum's excellent thermal conductivity allows for efficient heat dissipation, further enhancing their performance in heat-intensive environments. However, it is important to note that aluminum's heat resistance is not as high as some other metals like steel or titanium, so in extremely high-temperature applications, alternative materials might be more appropriate.

- Q: This question asks for an overview of the various types of adhesives that are compatible with aluminum profiles.

- <p>Aluminum profiles can be bonded with several types of adhesives, each offering unique properties for different applications. Epoxy adhesives are strong and durable, suitable for high-strength bonding. Cyanoacrylate (super glue) offers fast bonding with good strength and is easy to use. Silicone adhesives are flexible and weather-resistant, making them ideal for outdoor applications. Polyurethane adhesives provide strong bonds with excellent flexibility and are resistant to moisture and chemicals. Acrylic adhesives are known for their versatility and strong bonds, while anaerobic adhesives cure in the absence of air and are often used for threaded fasteners. Each adhesive type has specific curing times and temperature resistance, so the choice depends on the specific requirements of the project.</p>

- Q: How do aluminum profiles contribute to LEED certification?

- Aluminum profiles can contribute to LEED (Leadership in Energy and Environmental Design) certification in several ways. Firstly, aluminum is a highly sustainable material. It is one of the most abundant elements on Earth and can be easily recycled without losing its quality. Using aluminum profiles in construction projects reduces the demand for new raw materials, conserves energy, and minimizes greenhouse gas emissions. This aligns with LEED's focus on reducing the environmental impact of buildings. Additionally, aluminum profiles are lightweight yet durable, allowing for efficient transportation and installation. This can contribute to LEED points in the category of Sustainable Sites, which encourages the use of materials and techniques that minimize impacts on ecosystems and reduce pollution during construction. Furthermore, aluminum profiles can be used to improve energy efficiency in buildings. By incorporating thermal breaks and insulation, aluminum profiles can help prevent heat transfer and reduce energy consumption for heating or cooling. This can contribute to LEED points in the Energy and Atmosphere category, which promotes the use of energy-efficient systems and materials. Moreover, aluminum profiles are resistant to corrosion and require minimal maintenance over their lifespan. This durability can contribute to LEED points in the Materials and Resources category, which encourages the use of long-lasting, low-maintenance materials that minimize waste and the need for replacement. In conclusion, aluminum profiles contribute to LEED certification by promoting sustainability, reducing environmental impacts, improving energy efficiency, and enhancing the durability of buildings. By considering the use of aluminum profiles in construction projects, designers and builders can achieve LEED credits and contribute to a more sustainable future.

- Q: What are the different alloys available for aluminum profiles?

- There are several different alloys available for aluminum profiles, including 6061, 6063, and 6082. These alloys vary in their composition and properties, allowing for different levels of strength, corrosion resistance, and machinability. Each alloy has its own unique characteristics, making them suitable for various applications and industries.

- Q: How much is the aluminium frame Aonaike surface over three thickness? And three prism specifications?

- The thickness of the aluminum profile is 1.8mm, and the size of the three prism is 136126100,80.

- Q: Can aluminum profiles be used in electrical switchgear manufacturing?

- Yes, aluminum profiles can be used in electrical switchgear manufacturing. Aluminum is a lightweight and durable material that offers good electrical conductivity, corrosion resistance, and thermal properties. It can be easily shaped and fabricated into various profiles to meet the specific requirements of switchgear manufacturing processes.

- Q: How can I distinguish the aluminum profiles in the building and the aluminum in the industry?

- Door frames, aluminum profiles and doors and windows, aluminum profiles are in the building. Your picture is a line of scaffold material, usually in industrial material.

- Q: Can aluminum profiles be recycled indefinitely?

- Yes, aluminum profiles can be recycled indefinitely. Unlike other materials, aluminum does not degrade during the recycling process. It can be melted down and reshaped into new profiles without losing its inherent properties. This essentially means that aluminum profiles have a never-ending life cycle. Recycling aluminum requires significantly less energy and resources compared to producing new aluminum, making it an environmentally sustainable option. Moreover, the recycling process can be repeated countless times without any loss in quality, making aluminum one of the most recycled materials in the world.

- Q: This question asks for a list of various types of adhesives that are typically used in conjunction with aluminum profiles in construction projects.

- <p>Common types of adhesives used with aluminum profiles in construction include epoxy resins, which offer strong bonding and resistance to chemicals and temperature changes; polyurethane adhesives, known for their flexibility and durability; silicone adhesives, which are excellent for sealing and bonding in a wide range of temperatures; acrylic adhesives, valued for their versatility and quick setting times; and cyanoacrylate or 'super glue', which bonds quickly and is great for small, precise applications. Each type has unique properties that make it suitable for different construction needs.</p>

- Q: How do aluminum profiles perform in fire-resistant structures?

- Aluminum profiles perform exceptionally well in fire-resistant structures due to their inherent fire-resistant properties. Aluminum has a high melting point and does not contribute to the spread of fire, making it a preferred choice for construction materials in fire-resistant structures. Additionally, aluminum profiles maintain their structural integrity even in high temperatures, providing excellent fire protection and ensuring the safety of the building and its occupants.

Send your message to us

Structural Aluminum Extrusion Profiles - Aluminium S-Profile for Building Constructions

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 2000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords