Delmar Company Aluminium Profiles for Ship Mast

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

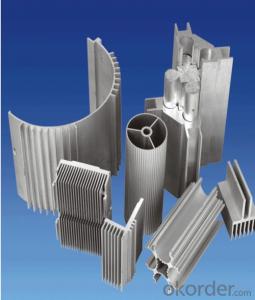

Aluminium Profiles for ship mast

1. Usage:Aluminium Profiles for ship mast

2. Surface: Mill surface treatment

3. Alloy:6082T6 alloy temper

4. Size:various dimensions to meet customer’s requirement

5. Advantage:

The alloy temper of this ship mast is nonheat treatment strengthened alloy which has medium level hardness, good corrosion resistance and weldability. In the atmosphere of sea ocean water, such alloy not only has excellent performance of the general corrosion resistance, and also can eliminate spalling corrosion and inter-granular corrosion.

6. Package:Two pcs of profiles interleaving inserted together to be a couple, ten pcs of profiles wrapped tightly in one bundle.

7. Life time: Last for 50 years

8. Standard: EN755-9 standard

- Q: Are aluminum profiles suitable for structural applications?

- Indeed, aluminum profiles prove to be fitting for structural applications. Boasting a lightweight composition, aluminum exhibits remarkable versatility, coupled with an exceptional strength-to-weight ratio, corrosion resistance, and durability. Consequently, it becomes an ideal choice for an array of structural purposes, encompassing architectural frameworks, bridges, aerospace structures, automotive frames, and industrial equipment. Moreover, the malleability of aluminum profiles permits effortless fabrication, welding, and joining, facilitating efficient construction and customization. By incorporating appropriate design and engineering considerations, aluminum profiles can ensure the essential strength and stability demanded by structural applications.

- Q: Can aluminum profiles be utilized in creating distinctive architectural structures?

- <p>Yes, aluminum profiles can be used to create unique architectural designs. They are favored for their strength, lightweight, and corrosion resistance. Architects can utilize aluminum's flexibility to design complex structures, such as intricate facades, modern window systems, and innovative support frameworks. Aluminum's adaptability allows for both functional and aesthetically pleasing designs, making it a popular choice in contemporary architecture.</p>

- Q: Are aluminum profiles suitable for greenhouse structures?

- Indeed, greenhouse structures find aluminum profiles to be well-suited. Given its durability, lightweight properties, and resistance to corrosion, aluminum has become a favored material for constructing greenhouse frames. The use of aluminum profiles ensures robustness and steadiness, enabling the creation of resilient greenhouse structures capable of enduring diverse weather conditions. Moreover, aluminum proves to be easily malleable and readily adaptable to meet specific design needs. Furthermore, its low-maintenance nature necessitates only minimal upkeep over time. All in all, aluminum profiles present themselves as a dependable and pragmatic option for greenhouse structures.

- Q: Where is the aluminum profile market in Tianjin?

- Industrial aluminium profile standard profile:1530156015901640, 2020204020803030, 30R arc, 3030W 3030, 3030R, 3030RQ, 3060309030150, 4040A, 4040Q, 4040L4040W, 4040Z, 40R arc, 40 right angle, 4060Q, 4060L, 4060Z, 4080, 4080L, 4080W, 8080, 8080W, 606080120100100, 1201204012045454545L 4545Q 4545W 45909090 9090W 45R 4560 4560W 501005050501006060 6060L arc 4545RQ (1530-120120 Series) line industrial profiles and accessories can be assembled into processing products: tool rack (car), operation table, special tool cart, line table, product display, LCD panel, sun room, display cabinets, display rack, mechanical seal cover, shelves, product testing equipment, non-standard equipment, industrial fence, plotter, testing equipment, laboratory equipment, biological machine, labeling machine, production line, motor rotor bracket, electronic products production line, production line, line table, equipment protection barrier, LCD panel production equipment

- Q: What are the different colors available for aluminum profiles?

- The different colors available for aluminum profiles can vary depending on the manufacturer or supplier. However, some common color options include natural silver, black, white, bronze, gold, and various shades of gray. Additionally, there are also custom color options available where aluminum profiles can be powder coated or anodized in a wide range of colors to suit specific design requirements.

- Q: What are the possible alternatives to aluminum extrusions in the construction industry?

- <p>Yes, there are several alternative materials that can replace aluminum extrusions in construction projects. These include steel, which is strong and durable but heavier; fiberglass, known for its lightweight and corrosion resistance; and thermoplastics like PVC, which are cost-effective and easy to work with. Each material has its own advantages and limitations, and the choice depends on the specific requirements of the project, such as strength, weight, cost, and environmental factors.</p>

- Q: Can aluminum profiles be used in elevator or escalator systems?

- Yes, aluminum profiles can be used in elevator or escalator systems. Aluminum is a lightweight and durable material that offers structural strength and corrosion resistance, making it suitable for various construction applications. It is commonly used in the manufacture of elevator and escalator components such as handrails, frames, panels, and supports.

- Q: Is it possible to recycle aluminum profiles through the current recycling systems in place?

- <p>Yes, aluminum profiles can be recycled using existing recycling programs. Aluminum is one of the most recycled materials globally due to its non-toxic nature and the energy efficiency of recycling it. Most recycling programs accept aluminum, and aluminum profiles can be collected, sorted, and processed to be melted down and reused in new products. It's important to check with local recycling facilities to understand their specific guidelines and requirements for recycling aluminum profiles.</p>

- Q: What are the features of the poor aluminum profiles?

- Low precision, bad feel, and so on, some inferior shape.You'd better go to the manufacturer you trust.

- Q: The company must tender, but it needs material certification, but what do not know exactly?

- Enterprise legal person business license, China Quality Association approved, the national industrial product production permit, 9001 certificate, a copy of tax registration certificate. Surely that will be enough

Send your message to us

Delmar Company Aluminium Profiles for Ship Mast

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords