Aluminum Profiles 6061-T5

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

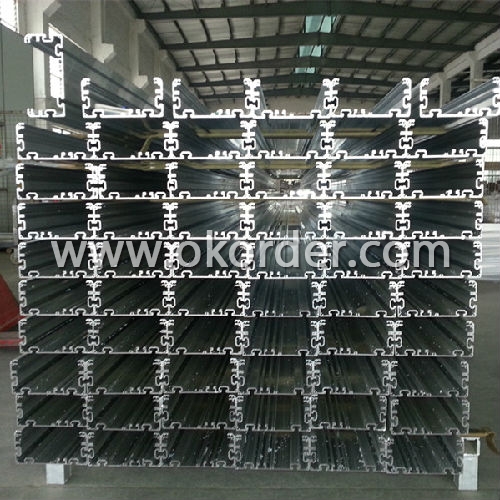

1 Specifications of Aluminum Profiles 6061-T5

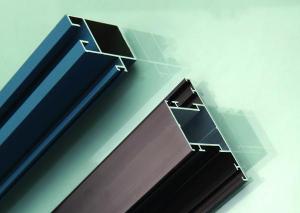

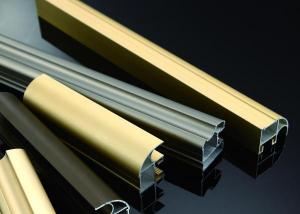

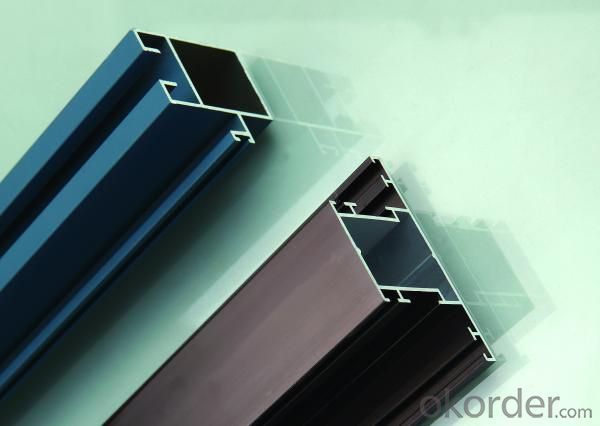

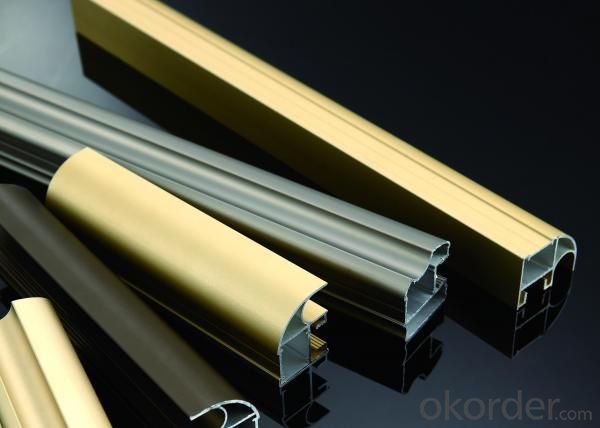

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Profiles 6061-T5

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

3 Packaging & Delivery of Aluminum Profiles 6061-T5

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of Aluminum Profiles 6061-T5

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q: Aluminum Alloy rail safety glass balcony design, Aluminum Alloy profiles for what is standard specifications?

- The specifications and sizes of aluminum doors and windows are mainly marked by the height dimension of the section of the profiles (used in aluminium alloy doors and windows, and the thickness of the door and window frames), and form a series of dimensions. Aluminum doors and windows profiles are 40, 45, 50, 55, 60, 65, 70, 80, 90, 100mm and other dimensional series. Among them, the size of aluminum alloy window is smaller, and the size of aluminum alloy door is larger.1, aluminum doors and windows dimensioning the same series, not necessarily aluminum windows and doors section shape and size are the same. The aluminum alloy door and window profiles of the same size series are quite complex in shape and size. Must be analyzed and treated in accordance with the drawings.2 、 the aluminum door and window profile is divided into solid section and hollow section according to the shape of the section, and the application of the hollow profile is larger.3, aluminum doors and windows profiles of wall thickness, for aluminum alloy window of not less than 1.4mm, with aluminum alloy door is not less than 2mm.4, aluminum door and window profiles of length, size, dividing ruler, double ruler and indefinite ruler three kinds. Fixed length generally not more than 6m, variable length is not less than 1m.

- Q: This question asks for an explanation of the various methods employed in the manufacturing of aluminum profiles.

- <p>Aluminum profiles are produced using several manufacturing processes, each suited to different applications and profile shapes. The primary methods include: Casting, where molten aluminum is poured into molds to form profiles; Extrusion, the most common process, where aluminum is pushed through a die to create long, continuous shapes; Rolling, used for creating flat or curved sheets and plates; Forging, which involves shaping aluminum by applying compressive forces; and Machining, where aluminum profiles are cut and shaped using tools. Each process has its advantages and is chosen based on the desired profile's complexity, strength, and cost-effectiveness.</p>

- Q: Are aluminum profiles fire-resistant?

- Aluminum profiles are commonly acknowledged as being fire-resistant due to their non-combustible nature and inability to ignite or support combustion. Their high melting point of approximately 660 degrees Celsius surpasses typical fire temperatures. Nevertheless, it is crucial to acknowledge that while aluminum itself exhibits fire resistance, the accessories or components utilized alongside aluminum profiles, like gaskets or seals, may not possess the same level of fire resistance. These accessories might possess varying fire ratings, potentially influencing the overall fire resistance of the assembly. In specific scenarios, fire-resistant coatings or treatments can be applied to aluminum profiles to enhance their fire performance. These coatings offer supplementary protection and bolster the fire resistance of the profiles. To ensure fire safety in a particular application, it is always advisable to consult the manufacturer or supplier of the specific aluminum profile. They can provide insights into the profile's fire-resistant properties and suggest additional measures that can be taken to enhance fire safety.

- Q: What are the possible alternatives to aluminum extrusions in the construction industry?

- <p>Yes, there are several alternative materials that can replace aluminum extrusions in construction projects. These include steel, which is strong and durable but heavier; fiberglass, known for its lightweight and corrosion resistance; and thermoplastics like PVC, which are cost-effective and easy to work with. Each material has its own advantages and limitations, and the choice depends on the specific requirements of the project, such as strength, weight, cost, and environmental factors.</p>

- Q: What are the different grades of aluminum used in profiles?

- The different grades of aluminum commonly used in profiles include 6061, 6063, and 6082. These grades vary in terms of their mechanical properties, corrosion resistance, and suitability for different applications.

- Q: Are aluminum profiles suitable for use in the telecommunications industry?

- Yes, aluminum profiles are suitable for use in the telecommunications industry. Aluminum profiles offer a lightweight and durable solution for various applications in the telecommunications field, such as antenna mounts, equipment racks, enclosures, and cable management systems. They offer excellent corrosion resistance, thermal conductivity, and electromagnetic shielding properties, making them a reliable choice for supporting and protecting telecommunications equipment. Additionally, aluminum profiles can be easily customized and fabricated to meet specific design requirements, making them highly versatile for use in the telecommunications industry.

- Q: Can aluminum profiles be used for access control systems?

- Yes, aluminum profiles can be used for access control systems. Aluminum profiles are commonly used in the construction of access control systems due to their durability, lightweight nature, and corrosion resistance. They provide a sturdy framework for mounting access control devices such as card readers, keypads, and biometric scanners. Additionally, aluminum profiles offer flexibility in design and can be easily customized to fit specific requirements of access control systems.

- Q: Can aluminum profiles be used in material handling equipment manufacturing?

- Yes, aluminum profiles can be used in material handling equipment manufacturing. Aluminum profiles are lightweight, corrosion-resistant, and have high strength-to-weight ratio, making them ideal for constructing various components of material handling equipment. These profiles can be easily customized and assembled to create frames, support structures, conveyor systems, and other parts of material handling equipment. Additionally, aluminum profiles offer flexibility in design, allowing for easy modifications or additions to the equipment as per specific requirements.

- Q: Can aluminum profiles be an alternative to wood in construction?

- Yes, aluminum profiles can certainly be a viable alternative to wood in construction. Aluminum is lightweight, durable, and resistant to rust and corrosion, making it an excellent choice for various construction applications. Additionally, aluminum profiles offer flexibility in design, are easy to install, and require minimal maintenance. They can be used for structural components, windows, doors, cladding, and other construction elements, providing a sustainable and cost-effective solution compared to wood.

- Q: What are the weatherproofing properties of aluminum profiles?

- Due to their inherent characteristics and manufacturing processes, aluminum profiles possess excellent weatherproofing properties. This is due to aluminum being a naturally corrosion-resistant material, allowing it to endure exposure to different weather conditions without deteriorating or rusting. It forms a protective layer of oxide on its surface, serving as an additional barrier against moisture and preventing further corrosion. Moreover, various weatherproofing techniques can further enhance aluminum profiles. Anodizing is a common method where the aluminum surface undergoes an electrolytic process to create a thicker and more durable oxide layer. This not only improves weather resistance but also enhances resistance to scratching and wear. Furthermore, aluminum profiles can be coated with protective finishes like powder coating or liquid paint. These coatings not only add aesthetic appeal but also provide an extra layer of protection against UV radiation, moisture, and other weather elements. Powder coating, in particular, offers exceptional durability and resistance to fading, chipping, and cracking. Additionally, aluminum profiles can be designed to incorporate weatherproof features such as gaskets, seals, and thermal breaks. These elements establish a tight seal between the profile and other building components, preventing water infiltration, air leakage, and thermal transfer. They contribute to maintaining a comfortable indoor environment, reducing energy consumption, and enhancing the overall weatherproofing performance of the aluminum profiles. In summary, the weatherproofing properties of aluminum profiles make them a popular choice for a wide range of applications, including windows, doors, curtain walls, roofing systems, and outdoor furniture. Their ability to withstand harsh weather conditions, resistance to corrosion, and availability of protective coatings make them a dependable and long-lasting option for both residential and commercial projects.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 1991 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Profiles 6061-T5

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords