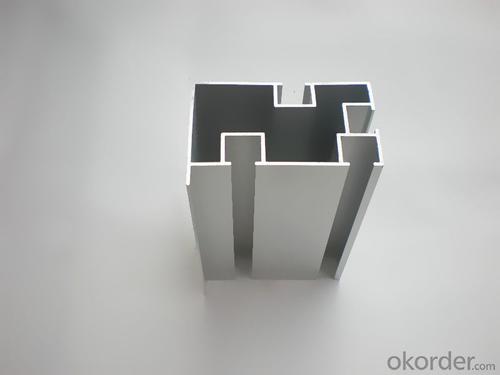

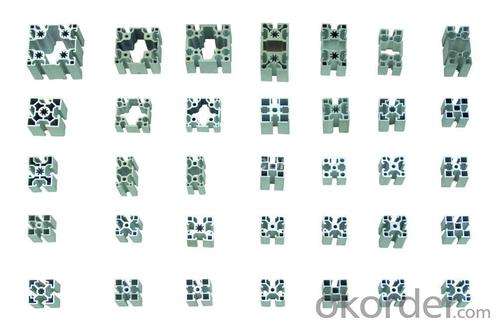

Industrial Aluminum Extrusion Profiles T-Slot

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: This question asks for methods to protect aluminum profiles from water damage during the installation and usage phases.

- <p>To prevent water damage to aluminum profiles during installation or use, follow these steps: 1. Ensure the aluminum profiles are properly sealed with a high-quality sealant to prevent water penetration. 2. Use corrosion-resistant fasteners and hardware to avoid rusting. 3. Install drainage systems to direct water away from the profiles. 4. Regularly inspect and maintain the profiles to identify and repair any damage promptly. 5. Avoid installing profiles in areas with high humidity or direct exposure to rain. 6. Use protective coatings or paints that are water-resistant and compatible with aluminum. 7. Keep the profiles clean and free from dirt or debris that can trap moisture. By following these precautions, you can significantly reduce the risk of water damage to aluminum profiles.</p>

- Q: Are there any specific requirements for transporting and storing aluminum profiles?

- Yes, there are specific requirements for transporting and storing aluminum profiles. Aluminum profiles should be handled with care to prevent any damage or deformation. During transportation, they should be properly secured to avoid shifting or falling. It is recommended to use protective packaging and cushioning materials to prevent scratches or dents. When storing aluminum profiles, they should be kept in a clean and dry area to prevent corrosion. It is advisable to stack them horizontally or on racks to avoid bending or warping. Additionally, they should be stored away from direct sunlight and extreme temperatures.

- Q: What are the strategies to reduce the environmental footprint when utilizing aluminum profiles in construction projects?

- <p>To minimize the environmental impact of using aluminum profiles in construction, consider the following strategies: Use recycled aluminum whenever possible, as it requires significantly less energy to produce than new aluminum. Opt for energy-efficient manufacturing processes and choose suppliers with strong environmental credentials. Design for disassembly and recycling to facilitate the reuse of aluminum profiles at the end of their life. Implement sustainable construction practices that reduce waste and emissions. Finally, educate stakeholders about the importance of sustainable materials and encourage the adoption of eco-friendly practices throughout the construction process.</p>

- Q: This question asks about the various types of fastening mechanisms used to attach exterior walls to the structural frames of buildings.

- <p>Different types of fasteners used to secure exterior walls to building frames include nails, screws, bolts, and anchors. Nails are commonly used for wood-framed structures, while screws offer greater holding power. Bolts are used in steel or concrete structures and can be either through-bolts or expansion bolts. Anchors, such as masonry or concrete anchors, are used for securing to masonry or concrete walls. Additionally, adhesives and mechanical fasteners like clips and brackets are also used depending on the material and design of the exterior wall and building frame.</p>

- Q: This question asks for an enumeration of the various types of aluminum profiles that are commonly utilized in interior wall systems.

- <p>Aluminum profiles for interior wall systems come in various types, each serving a specific purpose. These include: 1. Cover Profiles, which conceal the joints between wall panels; 2. Angle Profiles, used for creating corners and edges; 3. Connecting Profiles, facilitating the attachment of panels; 4. Support Profiles, providing structural support; 5. Joint Profiles, for aligning and securing panels at their joints; 6. Decorative Profiles, adding aesthetic appeal; 7. Insulation Profiles, for thermal insulation; and 8. Sealing Profiles, to prevent air and moisture infiltration. Each type of profile is designed to meet specific architectural and functional requirements, contributing to the overall integrity and appearance of the interior wall system.</p>

- Q: Explain if aluminum profiles can be utilized in constructing energy-efficient building systems and if so, how they contribute to energy efficiency.

- <p>Yes, aluminum profiles can be used to create energy-efficient building systems. They are lightweight yet strong, which reduces the energy required for construction. Aluminum profiles also have excellent thermal conductivity, allowing them to be used in double-glazed windows and doors, improving insulation and reducing heat loss. Additionally, aluminum can be easily recycled, reducing the energy needed for new materials. Their high reflectivity can also help in reducing heat absorption, further contributing to energy efficiency.</p>

- Q: Can aluminum profiles be custom-designed or customized?

- Yes, aluminum profiles can be custom-designed or customized according to specific requirements. Aluminum is a highly versatile material that can be easily shaped and manipulated into different forms. Customizing aluminum profiles allows for the creation of unique shapes, sizes, and finishes to meet the specific needs of various applications. Custom design and customization of aluminum profiles can involve altering dimensions, creating intricate shapes, adding slots or holes for assembly, incorporating specific features or accessories, and even applying various surface treatments or coatings. This flexibility in design and customization enables aluminum profiles to be used in a wide range of industries and applications, such as construction, automotive, aerospace, electronics, and more. The process of customizing aluminum profiles typically involves collaboration between the manufacturer and the customer. The manufacturer will work closely with the customer to understand their requirements, provide technical support, and offer design solutions that meet their specific needs. This may include creating prototypes, conducting tests, and making adjustments until the desired custom design is achieved. Overall, aluminum profiles can indeed be custom-designed or customized to suit specific requirements, making them a preferred choice for many industries seeking unique and tailored solutions.

- Q: Are aluminum profiles weather-resistant?

- Yes, aluminum profiles are weather-resistant. Aluminum is known for its excellent corrosion resistance and ability to withstand various weather conditions such as rain, snow, UV radiation, and extreme temperatures. This makes aluminum profiles a popular choice for outdoor applications such as windows, doors, and outdoor furniture.

- Q: How to use aluminum profile on the side of roller conveyor?

- 1, aluminum has four T groove, convex roller bearing seat or shaft seat made matched with the vertical direction, and then through the bolt and nut groove can be fixed bearing or shaft seat, the roller spacing can be adjusted.2, with Thomas, first according to Thomas roller is fixed on the inner side section spacing, then the roller milling flat shaft directly to the groove in the thomas.

- Q: What are the weight capacities of aluminum profiles for shelving systems?

- The weight capacities of aluminum profiles for shelving systems can differ based on a variety of factors, including the profiles' dimensions, the shelving system's design, and the quality of the aluminum used. In general, aluminum profiles used for shelving systems can handle a substantial amount of weight. Nevertheless, it is important to acknowledge that the weight capacity of a shelving system also relies on other components like brackets, connectors, and the type of shelving material (e.g., wood, glass, or metal shelves) used. To obtain accurate weight capacity information, it is advisable to consult the manufacturer or supplier of the specific aluminum profile and shelving system. They can offer guidelines derived from their product specifications, engineering calculations, and testing. Additionally, proper installation, weight distribution, and regular maintenance are also vital factors in ensuring the overall strength and stability of a shelving system.

Send your message to us

Industrial Aluminum Extrusion Profiles T-Slot

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords