Aluminum Window Profile Customerized Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.22

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

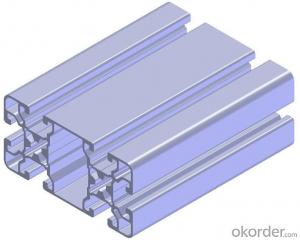

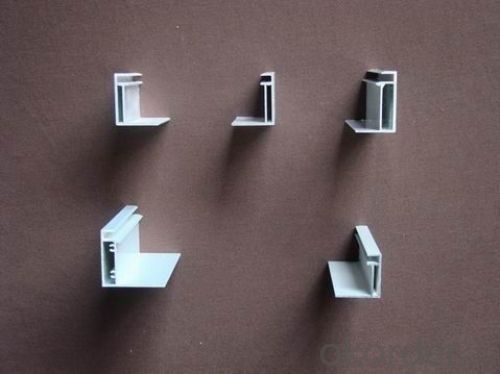

Aluminum Frame and Corner

Products Introduction of Aluminum Frame and Corner

Aluminum frame is made from aluminum and minerals. It's raw matrial for window frame, window frame, and other equipment frame. It's easy for construction, cost less, service longer than other materails. The size and design can be customerized.

Advantage of Aluminum Frame and Corner

-Build FLEXIBLE equipment, window, door.

-Bolt your structure together

-Build with Aluminum MORE EASILY

-Aluminum costs LESS

-Service life is more than 10 years

-Can be customerized

Specifications

(1) Product: Aluminium Frame;

(2) Material: Alloy 6063/6061/6005/6060, T5/T6;

(3) Finish: anodizing, powder coating, wooden, electrophoresis or any color;

(4) Size: customized, same as drawings or samples;

(5) Standard: High-quality;

(6) Characteristics: strong, stylish, durable, corrosion-resistant.

Aluminium Alloy: 6063, 6061, 6005, 6060 Thermal Treatment: T5, T6

Section Shapes

I, U, T, C, Z, L, H, square, round, flat, hollow, t-slot, and other complicated shapes by custom design.

Surface treating

Mill / Anodizing (oxidation) / Sand blasting / Powder Coating / Electrophoresis / PVDFCoating / Wood effect.

Application

1) - for Window and door frames, for Wardrobe cabinet sliding doors, kitchen, for Building curtain glass walls

2) -for Fencing, Rail, Deck and Frame.

3) - for Solar panel frames, solar mounting / roofing brackets

4) - for Industry assembly lines equipment.

5) - for Heatsinks, for LED lighting.

7) - other by custom design size and dimension

FAQ

-What's your company profile?

We CNBM is the largest building material supplier of China. We are Chinese government owned corporation, which takes the 267th place in WOLD FORTUNE 500 CORPORATION. We own the largest prodcution base in North and South of China. With more than 15 warehouses and offices in different countries, our products sell very well all over the world. We have whole quality control system. We'll be your reliable partner.

-Which kind of payment do you usually support?

TT, LC at sight.

-Can you provide samples?

Yes, we provide free of charge samples, you just need to pay for the delivery.

Photos:

- Q: Can aluminum profiles be used in the production of agricultural equipment?

- Aluminum profiles have the potential to be utilized in the manufacturing of agricultural equipment. The versatility and lightweight characteristics of aluminum provide numerous benefits for agricultural applications. Its resistance to corrosion is crucial when considering equipment that is exposed to outdoor conditions and various farming chemicals. Moreover, aluminum profiles have the capability to be easily molded and customized to meet specific design requirements, enabling the creation of intricate and functional agricultural equipment. The lightweight nature of aluminum also simplifies the transportation and handling of the equipment, resulting in reduced labor costs. Additionally, aluminum profiles are recyclable, making them an environmentally conscious choice for the production of agricultural equipment. In conclusion, incorporating aluminum profiles into agricultural equipment can enhance durability, efficiency, and sustainability within the farming industry.

- Q: How do you protect aluminum profiles from scratching or damage?

- There are multiple methods available for safeguarding aluminum profiles against scratches or damage. To begin with, a commonly used approach involves applying a protective coating or finish. This can be accomplished by utilizing paints, lacquers, or powder coatings that serve as a barrier between the aluminum surface and external elements. These coatings not only enhance the appearance but also offer protection against scratches, corrosion, and other forms of damage. Another effective temporary solution is the utilization of protective film or tape. These films or tapes can be directly applied onto the aluminum profiles, acting as a shield. Generally transparent, these films can be easily peeled off once the profiles are installed or ready for use. A different technique involves handling and transporting the aluminum profiles with caution. This entails the use of appropriate handling equipment, such as gloves, to avoid direct contact with the surface. Additionally, the use of protective packaging materials like bubble wrap or foam can provide cushioning during transportation, preventing scratches or dents. Regular cleaning and maintenance of the aluminum profiles is also crucial. Dust, dirt, and debris can act as abrasives, causing scratches over time. Cleaning with a soft cloth or sponge and mild detergent on a regular basis can help eliminate these particles and preserve the profile's appearance. Lastly, implementing proper storage practices is of utmost importance. Storing aluminum profiles in a dry and clean environment, away from sharp objects or heavy items, can minimize the risk of scratching or damage. The use of racks or shelves with protective padding can provide an additional layer of protection. By adhering to these measures, aluminum profiles can be effectively safeguarded against scratches or damage, ensuring their durability and preserving their aesthetic appeal.

- Q: This question asks for guidance on selecting the appropriate aluminum profiles for a construction project.

- <p>Choosing the right aluminum profiles for your building project involves several steps. First, consider the specific requirements of your project, such as load-bearing capacity, aesthetic preferences, and environmental conditions. Consult with engineers or architects to determine the appropriate strength, size, and shape of the profiles. Next, evaluate the quality of the aluminum, ensuring it meets industry standards for durability and resistance to corrosion. Look for profiles with good thermal insulation properties and UV resistance to maintain performance over time. Finally, consider the cost-effectiveness and availability of the profiles, as well as the ease of installation and maintenance. Always opt for reputable suppliers to ensure you receive high-quality products that meet your project's needs.</p>

- Q: What kind of self tapping screw can attack aluminum profile?

- Self tapping screws are used for connecting between thin metal plates. When connecting to the connecting piece for the threaded hole, then tapping screws into the threaded hole of the connecting piece. Because of the self tapping screw thread surface has higher hardness (more than 45HRC), the attack a thread in the threaded hole of the connecting piece, thereby forming a connection.Aluminum material than steel soft, generally in accordance with GB screws can be of aluminum, is recommended to hit bottom hole in the needed position.The following is the national standard for self tapping screws:GB/T15856.1-2002 cross recessed countersunk head tapping screws, material: 20Mn 15MnBGB/T15856.2-2002 cross recessed countersunk head drilling self tapping screw, material: 20Mn 15MnBGB/T15856.3-2002 cross recessed semi countersunk head drilling self tapping screw, material: 20Mn 15MnB

- Q: This question asks for a list of various materials that are used in the production of aluminum profiles.

- <p>Aluminum profiles are primarily made from aluminum alloys, which are composed of aluminum combined with other elements to enhance their properties. Common materials used include 6063 aluminum alloy, known for its excellent extrudability and weldability, making it ideal for a wide range of applications. 6061 aluminum alloy is also used for its high strength and good corrosion resistance, suitable for structural components. Other alloys such as 6082 and 7075 are utilized for their superior strength-to-weight ratios, often found in aerospace and automotive industries. Additionally, aluminum profiles may incorporate materials like magnesium, silicon, copper, and manganese to achieve specific mechanical properties or corrosion resistance tailored to particular applications.</p>

- Q: This question asks about the various surface treatments or finishes that can be applied to aluminum profiles used in window and door frames.

- <p>Aluminum profiles used for windows and doors can have several finishes to enhance their appearance and durability. These include anodizing, which creates a protective oxide layer; powder coating, offering a wide range of colors and textures; thermal spraying, which applies a coating to improve resistance to wear; and electrophoretic coating, which provides a smooth, even finish. Additionally, there are finishes like polishing for a shiny look, brushing for a matte appearance, and wood grain transfer for a natural aesthetic. Each finish serves a specific purpose, from enhancing visual appeal to providing corrosion resistance and UV protection.</p>

- Q: Explain the advantages of utilizing aluminum profiles in the construction industry.

- <p>Aluminum profiles offer several benefits in construction, including high strength-to-weight ratio, which means they are strong yet lightweight. This reduces the load on structures and facilitates easier handling and installation. They are also corrosion-resistant, ensuring longevity and low maintenance costs. Aluminum profiles are recyclable and environmentally friendly, contributing to sustainable construction practices. Their malleability allows for versatile design and customization, accommodating various architectural needs. Additionally, they have excellent thermal conductivity, which can be beneficial for heat management in buildings. Lastly, their aesthetic appeal and modern look enhance the visual appeal of construction projects.</p>

- Q: Can aluminum profiles be used for solar power systems?

- Yes, aluminum profiles can be used for solar power systems. Aluminum is a widely used material in the construction of solar panels and their support structures. It is preferred for its lightweight nature, high strength-to-weight ratio, and excellent corrosion resistance. Aluminum profiles are often used for the framing and mounting of solar panels, as they provide structural stability and durability. Additionally, aluminum is easily recyclable, making it an environmentally friendly choice for solar power systems.

- Q: This question asks for guidance on selecting suitable aluminum profiles for a construction project.

- <p>To choose the right aluminum profiles for your building project, consider the following: 1. Load-bearing capacity: Select profiles that can withstand the weight and stress of your structure. 2. Application: Choose profiles suitable for the specific application, such as window frames, curtain walls, or support beams. 3. Aesthetics: Opt for profiles that match your project's design and architectural style. 4. Durability: Look for high-quality aluminum with good corrosion resistance and weather resistance. 5. Cost: Compare prices and choose profiles that offer the best value for money. 6. Supplier reputation: Work with reputable suppliers known for quality products and reliable service. Consult with engineers or architects to ensure you select the most appropriate profiles for your project's needs.</p>

- Q: What are the various standards and regulations governing the use of aluminum profiles in construction?

- <p>Aluminum profiles in construction are governed by a variety of standards and regulations that ensure their quality, safety, and performance. These include ISO standards such as ISO 7039 for anodized aluminum and ISO 9001 for quality management systems. National standards like ASTM B221 in the USA and EN 755 in Europe specify mechanical properties and chemical composition. Building codes such as the International Building Code (IBC) and Eurocode 9 also provide guidelines for the use of aluminum in construction. Additionally, there are specific regulations for fire resistance, sustainability, and environmental impact, like the European CE marking for construction products. Compliance with these standards is crucial for manufacturers and builders to ensure the reliability and safety of aluminum profiles used in construction projects.</p>

Send your message to us

Aluminum Window Profile Customerized Design

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.22

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords