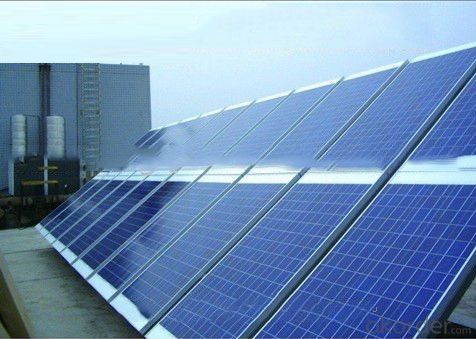

T Slot Extruded Aluminum Solar Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

ALUMINUM SOLAR PROFILE

Industrial aluminium profile

1)Material : 6063 6061 6060 and different aluminium alloy

2)Status:T4 T5 T6 or other special status

3)Surface treatment: mill finish, anodized sliver ,anodized bronze, anodized champagne, anodized black pearl, various power coating color, electrostatic sliver, electrostatic champagne, electrostatic golden, electrostatic titanium , machine polish sliver, machine polish bronze, wooden grain color, and Fluorocarbon spraying.

4)Annual capacity : 120000TON

5)Quality : China Nation Standard GB/T 5237 2008 (advanced class)

6)Use: can be widely using aluminium window, door, curtain wall, hand railing , normal aluminium profile, decorative and industrial aluminium profile

7)Advantage: Famous Brand reasonable&market price, soonest delivery and good after sale- service

8)Type of package:protection foam+heat contracted plastic film. / wooden packing / Metal pallet or depand on clientspecial requirement.

9)Payment term:T/T:30% of total value as deposite should paid by T/T within 3 days when confirmation ,and the remaining sum should be paid by T/T before delivery.L/C: 100% at sight

10)Delivery Day: 15-30days

11)Honor : CHINA FAMOUS TRADEMARK, CHINA TOP BRAND, ISO9001-2000, CHINA SQUARE&ROUND COMMITTEE DNV

- Q: This question asks for the various types of aluminum profiles that are utilized in roofing systems.

- <p>Aluminum profiles for roofing systems come in various types, each serving specific purposes. Common types include: 1. <strong>Gutter Profiles</strong>: Used for collecting and directing rainwater from the roof. 2. <strong>Fascia Profiles</strong>: Cover the ends of rafters and provide a finished edge to the roof. 3. <strong>Soffit Profiles</strong>: Installed under the eaves to allow ventilation and conceal the underside of the roof. 4. <strong>Purlin Profiles</strong>: Support the roof sheeting and are placed perpendicular to the rafters. 5. <strong>Rafter Profiles</strong>: Mimic traditional wooden rafters and provide structural support. 6. <strong>Roof Ridge Profiles</strong>: Cap the ridge of the roof, where two slopes meet. 7. <strong>Hip and Valley Profiles</strong>: Used at the intersection of two sloping roof surfaces. Each profile is designed to withstand weather conditions and provide durability, with specific dimensions and shapes tailored to the roofing system's requirements.</p>

- Q: Can aluminum profiles be used for escalator steps?

- No, aluminum profiles are not typically used for escalator steps. Escalator steps are designed to bear significant weight and withstand constant foot traffic, making them subject to high levels of stress and wear. Therefore, escalator steps are usually made from durable materials such as steel or strong composite materials that can withstand heavy loads and provide long-lasting performance. While aluminum profiles may have various applications in architectural or industrial settings, they are not commonly used for escalator steps due to their comparatively lower strength and potential for deformation under heavy loads.

- Q: What are the different surface brushing options for aluminum profiles?

- There are several surface brushing options available for aluminum profiles, each offering unique aesthetics and functional characteristics. 1. Mechanical Brushing: This method involves using abrasive brushes or pads to create a uniform brushed pattern on the surface of the aluminum profile. It provides a consistent, linear finish that enhances the visual appeal of the material. Mechanical brushing also helps to hide minor surface imperfections and scratches, making it a popular choice for decorative applications. 2. Chemical Brushing: Chemical brushing, also known as chemical etching, involves applying a chemical solution to the surface of the aluminum profile. The solution selectively removes a thin layer of metal, creating a brushed effect. This process can be controlled to achieve different levels of brush intensity, giving manufacturers flexibility in creating the desired appearance. Chemical brushing is often used to create a matte or satin finish on aluminum profiles. 3. Sandblasting: Sandblasting is a surface treatment technique that involves propelling fine particles at high speeds onto the aluminum profile's surface. The abrasive particles remove the outer layer of the metal, resulting in a textured, brushed finish. Sandblasting can be adjusted to achieve different levels of roughness and depth, making it suitable for various applications. 4. Wire Brushing: Wire brushing is a manual technique where a wire brush is used to create a brushed pattern on the aluminum profile's surface. This method allows for precise control over the brushing direction and intensity, making it suitable for customized designs. Wire brushing can create both light and heavy brushed finishes, depending on the pressure applied and the type of brush used. 5. Anodizing: Anodizing is an electrochemical process that involves creating an oxide layer on the surface of the aluminum profile. This process not only enhances the material's corrosion resistance but also allows for the application of various decorative finishes, including brushed patterns. Anodized aluminum profiles can be mechanically brushed or chemically etched to achieve the desired brushed effect before the anodizing process. Overall, the choice of surface brushing option for aluminum profiles depends on the desired finish, functionality, and specific application requirements. Manufacturers often consider factors such as aesthetic appeal, durability, corrosion resistance, and ease of maintenance when selecting the appropriate surface brushing technique.

- Q: What is the price of fluorocarbon coated aluminum profiles, please?

- Powder sprayed surface of about 2W a meal, fluorocarbon two or three coated difference about 800 yuan, 2.5W a meal bar, depends on what brand products, this price is now according to the aluminum ingot price estimate

- Q: Is it possible to recycle aluminum profiles and repurpose them for construction purposes?

- <p>Yes, aluminum profiles can be recycled and reused as building materials. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to producing new aluminum from raw materials. Recycled aluminum maintains its strength and properties, making it suitable for various construction applications. This practice not only conserves natural resources but also reduces waste and environmental impact.</p>

- Q: Can aluminum profiles be used for agricultural or farming applications?

- Indeed, agricultural or farming applications can make use of aluminum profiles. They possess several advantages that make them appropriate for these purposes. To start with, aluminum is lightweight, making transportation and installation easy. This proves particularly beneficial in agricultural settings where mobility and flexibility are crucial. Moreover, aluminum boasts high resistance to corrosion, making it perfect for use in harsh environments like farms that often encounter moisture, chemicals, and fertilizers. By preventing rust, it ensures durability and longevity, reducing the need for frequent replacements. Additionally, aluminum profiles can be easily customized and fabricated to fulfill specific requirements. This flexibility enables the creation of structures such as greenhouse frames, support beams, shelving systems, and other components essential in agricultural operations. Furthermore, aluminum profiles are non-toxic and do not emit harmful substances into the surrounding environment. This characteristic ensures their safety for use in farming applications, where the well-being of animals and crops is of utmost importance. Lastly, aluminum is a sustainable material that can be recycled indefinitely, minimizing its environmental impact. This aligns with the increasing emphasis on sustainability in agriculture. To conclude, due to their lightweight nature, resistance to corrosion, adaptability, safety, and sustainability, aluminum profiles are indeed suitable for various agricultural and farming applications.

- Q: How do I install aluminum profiles?

- Follow these steps to install aluminum profiles: 1. Begin by selecting the desired location for the aluminum profile installation and ensure the surface is clean and debris-free. 2. Precisely and smoothly cut the aluminum profile to the required length using a saw or miter saw. 3. Create pilot holes at regular intervals along the marked installation area using a drill. These holes will serve as anchor points for the screws or bolts that will secure the aluminum profile. 4. Align the pilot holes on the aluminum profile with the corresponding holes on the surface. Insert screws or bolts through the holes and tighten them using a screwdriver or socket wrench. 5. If you are installing multiple aluminum profiles, repeat the process for each section, ensuring they are aligned and securely fastened. 6. Once all profiles are installed, inspect for any gaps or unevenness. Adjust and tighten the screws or bolts as necessary to ensure a snug fit. 7. Lastly, clean the installed aluminum profiles using a mild cleaning solution and soft cloth to remove any dirt or residue. Remember to wear appropriate safety gear, such as gloves and safety glasses, when handling tools and materials during the installation process.

- Q: Can aluminum profiles be used for access platforms?

- Access platforms can indeed make use of aluminum profiles. Aluminum, a material that is both lightweight and durable, finds wide application in the construction and industrial sectors. Renowned for its corrosion resistance and superior strength-to-weight ratio, aluminum is highly suitable for access platforms. The versatility of aluminum profiles allows for easy fabrication into diverse shapes and sizes, catering to the unique needs of an access platform. Furthermore, aluminum possesses the added benefits of being non-magnetic and non-sparking, rendering it advantageous in specific environments. All in all, the utilization of aluminum profiles for access platforms ensures a secure and dependable solution.

- Q: This question asks for a comparison between aluminum profiles and other building materials regarding their cost and performance.

- <p>Aluminum profiles are often more cost-effective than materials like steel or wood in the long run due to their durability and low maintenance requirements. They offer high strength-to-weight ratios, making them ideal for structures where weight is a concern. Additionally, aluminum profiles have excellent resistance to corrosion and weathering, which reduces the need for repainting or replacement over time. They are also energy-efficient, as they can help in reducing heat transfer, thus lowering energy costs for heating and cooling. However, the initial cost of aluminum profiles can be higher than some alternatives, but their long-term performance and low maintenance can offset this initial expense.</p>

- Q: This question asks about the impact of aluminum profiles on the sound insulation properties of a building.

- <p>Aluminum profiles can significantly affect the sound insulation of a building. They are often used in construction for their strength and lightweight properties. However, aluminum is a good conductor of sound, which can lead to sound transmission through the building structure. To enhance sound insulation, aluminum profiles are often combined with soundproofing materials such as acoustic foam or rubber seals. These materials help to absorb or block sound waves, reducing noise transmission. Additionally, the design and installation of aluminum profiles can also impact sound insulation; proper sealing and insulation techniques are crucial to minimize sound leakage.</p>

Send your message to us

T Slot Extruded Aluminum Solar Profile

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords