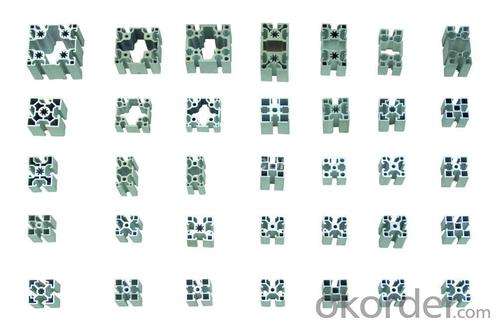

2020 T Slot Aluminum Profiles Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft,durable, lightweight, ductile and malleablemetal with appearance ranging from silvery to dull gray,depending on the surface roughness. It is nonmagnetic and does not easilyignite. A fresh film of aluminium serves as a good reflector (approximately92%) of visible light and an excellent reflector (as much as98%) of medium and far infrared radiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the density and stiffnessof steel. It iseasily machined,cast, drawn and extruded.

Aluminum Profile

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

- Q: Are aluminum profiles compatible with glass or other glazing materials?

- Yes, aluminum profiles are compatible with glass and other glazing materials. Aluminum is a popular material choice for window and door frames due to its strength, durability, and versatility. It can easily be combined with glass to create stylish and functional windows, doors, and other architectural elements. Aluminum profiles are designed to securely hold and support glass panels, providing a safe and stable glazing system. Additionally, aluminum profiles can also be used with other glazing materials such as polycarbonate or acrylic sheets, offering flexibility in design and construction. Overall, aluminum profiles offer excellent compatibility with glass and various glazing materials, making them a reliable choice for modern architectural projects.

- Q: This question asks for an explanation of the manufacturing process of aluminum profiles.

- <p>Aluminum profiles are made through a series of processes starting with the selection of high-quality aluminum ingots. These ingots are melted in a furnace and then extruded through a die to create the desired profile shape. The extrusion process involves forcing the molten aluminum through a shaped opening in the die, which gives the aluminum its final form. After extrusion, the profiles are cooled, straightened, and cut to length. They may then undergo secondary processes such as anodizing, powder coating, or painting for enhanced durability and appearance. Finally, the profiles are inspected for quality and packed for distribution.</p>

- Q: Aluminum prices are calculated by the meter, or how to quote the ah?

- Yes, for example, today's aluminum price, 10340+ processing fee 4000=14340, in addition to 1000 is equal to 14.34 yuan /KG

- Q: Which aluminum profile is better here in Guangdong?

- 1 、 aluminum material2, Zhong Wang aluminum3 Asia Aluminum4, Hing Fat aluminum5, the phoenix aluminum aluminum6, the United States and aluminum7, vibration or aluminum8 、 Nanshan aluminum material9, pillars of aluminum10, South South aluminum

- Q: Can aluminum profiles be used in construction?

- Indeed, construction can benefit from the utilization of aluminum profiles. This material boasts properties such as being lightweight, durable, and resistant to corrosion, thereby rendering it suitable for a multitude of construction purposes. Common applications encompass the construction of windows, doors, curtain walls, and roofing systems. Notably, the versatility of aluminum profiles permits the realization of intricate designs and structures. Furthermore, it is crucial to acknowledge that aluminum is an eco-conscious option for construction endeavors due to its high recyclability.

- Q: How do you ensure proper insulation with aluminum profiles?

- To ensure proper insulation with aluminum profiles, there are several key steps that can be taken. 1. Thermal break technology: Utilize aluminum profiles with thermal break technology. This involves the addition of a non-conductive material, such as polyamide, between the inner and outer aluminum sections. This helps to reduce heat transfer and improve insulation properties. 2. Proper sealing: Ensure that the aluminum profiles are properly sealed when installed. This includes using high-quality sealants and gaskets to prevent air leakage and create a tight seal. Pay attention to corners, joints, and any other potential areas of air infiltration. 3. Double or triple glazing: When using aluminum profiles for windows or doors, opt for double or triple glazing. This involves using multiple layers of glass with an air or gas-filled space in between. This extra layer of insulation helps to reduce heat transfer and improve energy efficiency. 4. Insulated frames: Consider using aluminum profiles with insulated frames. These frames have a layer of insulation material within them, further reducing heat transfer and improving thermal performance. 5. Thermal insulation accessories: Utilize additional thermal insulation accessories, such as thermal breaks, insulation tapes, or foam inserts. These can be installed within the aluminum profiles to enhance insulation properties and minimize thermal bridging. 6. Proper installation techniques: Ensure that the aluminum profiles are installed correctly by following manufacturer guidelines and recommendations. This includes using appropriate fasteners, avoiding gaps or spaces, and ensuring proper alignment and fit. By implementing these measures, proper insulation can be achieved with aluminum profiles, resulting in improved energy efficiency, reduced heat loss or gain, and increased comfort in buildings.

- Q: Will the aluminum profile be deformed at about 100 degrees?

- Subject to circumstances:1, aluminum material or brand2 、 what is the forming state of aluminum profile, such as conventional: O, T4, T5, T6 and so on3. How long is it within 100 degrees of heat? Continuous or intermittent entry, such as intermittent access, interval time, etc.4, the aluminum profile forming itself has a certain mechanical strength, such as tensile and yield and ductility, etc., but these mechanical strength is based on different materials (section shape) in different extrusion processing (T) Inferior.For example, a solid bar around 10MM, material 6061-T6, a short time into the furnace temperature of 100 degrees, the annealing temperature will make its hardness drops more quickly, then a long time will decrease, but no hardness.The material you say can not be deformed, the aforementioned points need to be clear, or any answer is biased, and I hope to help you!

- Q: What are the different welding options available for aluminum profiles?

- There are several welding options available for aluminum profiles, each with its own advantages and considerations. The most common welding methods for aluminum profiles include: 1. Tungsten Inert Gas (TIG) Welding: TIG welding is one of the most widely used methods for aluminum. It uses a non-consumable tungsten electrode to produce the weld, while an inert gas, such as argon, protects the weld area from atmospheric contamination. TIG welding offers excellent control over the heat input, resulting in high-quality, precise welds. It is suitable for thin aluminum profiles and provides a clean appearance, but it can be time-consuming and requires skilled operators. 2. Metal Inert Gas (MIG) Welding: MIG welding, also known as Gas Metal Arc Welding (GMAW), is another popular method for aluminum profiles. It uses a consumable wire electrode that continuously feeds into the weld pool, while an inert gas shield protects the weld area. MIG welding is faster than TIG welding and is suitable for both thin and thick aluminum profiles. However, it may produce more spatter and requires proper preparation and shielding gas selection. 3. Friction Stir Welding (FSW): Friction stir welding is a solid-state joining process that uses a rotating tool to generate heat and mechanically stir the aluminum profiles together. FSW is particularly suitable for thick aluminum profiles and offers high joint strength, excellent fatigue resistance, and minimal distortion. However, it requires specialized equipment and may not be suitable for all profile shapes. 4. Laser Beam Welding (LBW): Laser beam welding uses a highly concentrated laser beam to melt and join aluminum profiles. It provides a narrow and deep weld with minimal heat input, resulting in low distortion and high welding speeds. LBW is suitable for both thin and thick profiles, but it requires expensive equipment and skilled operators. 5. Resistance Spot Welding (RSW): Resistance spot welding uses electrical current and pressure to create welds by melting and joining aluminum profiles at specific points. RSW is commonly used for thin aluminum profiles and offers high productivity and repeatability. However, it requires access to both sides of the profiles and may leave visible marks on the surface. It is important to consider the specific requirements of your aluminum profile welding project, such as profile thickness, joint type, appearance, and production volume, to determine the most suitable welding method. Consulting with a welding professional or engineer can help ensure the best choice for your specific application.

- Q: Chengdu where to sell aluminum profiles of many businesses?

- This is what I learned on Baidu last year: look, maybe it will help you!Two days ago in the city to find the north gate, Xinshengda profile market have taken a little more, Sammy, the gold house electrical city only one sell Aluminum Alloy, Wanguan electrical didn't go to see, tailor steel city to ask a security guard said little or no 512, no Aluminum Alloy sold, only 512 of the next street there is a Aluminum Alloy sell (416 opposite the hospital).

- Q: This question asks for a list of various fasteners that are used to attach aluminum profiles to building frames.

- <p>There are several types of fasteners used to fix aluminum profiles on building frames, including: 1. Bolts and nuts, which provide a strong and secure connection. 2. Rivets, which are permanent and can't be undone once installed. 3. Screws, which are versatile and can be used in various applications. 4. Clamps, which hold profiles together without penetrating the material. 5. Adhesives, which bond profiles together chemically. 6. Welding, which joins profiles together by melting and fusing them. 7. C-clips and T-nuts, which are specialized fasteners designed for use with aluminum extrusions. The choice of fastener depends on the specific requirements of the project, such as load-bearing capacity, aesthetic considerations, and ease of assembly or disassembly.</p>

Send your message to us

2020 T Slot Aluminum Profiles Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords