Aluminum Hollow Profiles AA8XXX

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

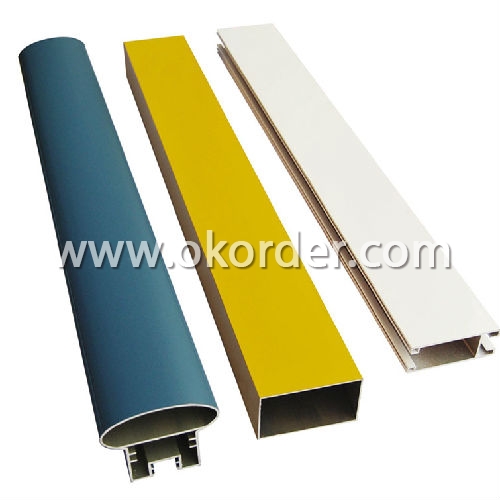

1 Specifications of Aluminum Profiles AA8xxx

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Profiles AA8xxx

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

3 Packaging & Delivery of Aluminum Profiles AA8xxx

Packaging: Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment: the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of Aluminum Profiles AA8xxx

aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q: What is the cost of aluminum profiles?

- Several factors can impact the cost of aluminum profiles, including the type of profile, required length and thickness, and prevailing market conditions. Typically, aluminum profiles are priced per linear foot or meter. Moreover, the price might be affected by the quality of the aluminum utilized and any necessary additional finishes or treatments. To obtain precise pricing details, it is recommended to reach out to local suppliers or manufacturers, as pricing can vary across regions.

- Q: 6063 aluminum manufacturers fail to notice how to write a written report

- Hello!You can search the Internet for unqualified written reports, and see if there are similar onesYou see, you sign the contract, which has not marked this point, say how to deal with substandard, you just need to copy the above, make a little change on the line

- Q: How to sell and sell industrial aluminium profiles?

- For the industrial aluminum profile enterprise, this is the most valuable customer resource, and also is the high-quality customer we usually call. Of course, the quality of customer mining, the most important thing is to discuss and communicate with customers. We must start from the position of customers, understand their requirements for products, know what they want to achieve the desired, can use their brains, for them to benefit by mutual discussion, analysis and reflection, so customers are thinking, anxious customers, so in fact, let customers choose our is the logical thing. It should be said that this is the most critical moment in the whole sale, so don't let yourself lose here.

- Q: The user is inquiring about the efficiency of aluminum profile recycling in their region and seeks details on how it can be done.

- <p>Yes, aluminum profiles can be recycled efficiently in most regions due to their high value and the relatively low energy required for recycling. The process typically involves collection, sorting, melting, and recasting into new aluminum products. To recycle aluminum profiles in your region, you can check for local recycling centers or scrapyards that accept aluminum. Some municipalities also have curbside recycling programs that include aluminum. Ensure that the profiles are clean and free of non-aluminum components before recycling to maximize their value and efficiency in the recycling process.</p>

- Q: Are aluminum profiles suitable for exhibition booths?

- Yes, aluminum profiles are suitable for exhibition booths. They are lightweight, durable, and easy to assemble and disassemble, making them ideal for creating versatile and portable booth structures. Additionally, aluminum profiles offer a sleek and modern aesthetic, allowing for customization and branding opportunities.

- Q: Can aluminum profiles be used in elevator or escalator systems?

- Indeed, elevator or escalator systems can incorporate aluminum profiles. These profiles possess qualities such as being lightweight, durable, and resistant to corrosion, rendering them appropriate for a range of uses, including the construction of elevator and escalator elements. Aluminum profiles can serve as the structural framework, handrails, cladding, and other components within an elevator or escalator system. Furthermore, these profiles can be effortlessly tailored and manufactured to fulfill the exact specifications of each project. The adaptability, ratio of strength to weight, and visual attractiveness of aluminum profiles establish them as a superb option for elevator and escalator systems.

- Q: What are the mechanical properties of aluminum profiles?

- Factors such as alloy composition, heat treatment, and manufacturing processes have an influence on the mechanical properties of aluminum profiles. These profiles are known for their excellent strength-to-weight ratio, making them both lightweight and strong. They possess good corrosion resistance, making them suitable for various applications in different environments. Furthermore, aluminum profiles are easily shaped and fabricated into desired designs due to their good formability. They also have high thermal and electrical conductivity, making them useful in applications such as heat sinks and electrical conductors. In addition, their low density contributes to their lightweight nature. In conclusion, the versatile mechanical properties of aluminum profiles make them widely used in industries including construction, transportation, and electronics.

- Q: This question asks if aluminum profiles can be used in cold weather conditions and if they maintain their properties in such environments.

- <p>Yes, aluminum profiles are suitable for use in cold climates. Aluminum is a durable material with excellent resistance to corrosion and weathering, which includes maintaining its integrity in low temperatures. It does not rust or degrade significantly in cold conditions, making it a reliable choice for construction and other applications in cold climates. However, it's important to consider the specific alloy and any protective coatings or treatments that may be necessary to ensure optimal performance in extreme cold.</p>

- Q: Can aluminum profiles be an alternative to steel in certain applications?

- Yes, aluminum profiles can be a viable alternative to steel in certain applications. Aluminum offers numerous advantages such as being lightweight, corrosion-resistant, and easily recyclable. It is commonly used in industries like aerospace, automotive, construction, and electronics. However, steel may still be preferred in applications requiring high strength or extreme temperatures. Ultimately, the choice between aluminum and steel profiles depends on specific requirements and considerations.

- Q: This question asks if aluminum profiles can be utilized in the construction of environmentally friendly buildings.

- <p>Yes, aluminum profiles can be used for green building applications. They are valued for their durability, recyclability, and energy efficiency. Aluminum is lightweight, which reduces the building's carbon footprint during transportation. It also has excellent thermal conductivity, allowing for better insulation and energy conservation. Additionally, aluminum can be recycled without losing its properties, contributing to a circular economy and reducing waste. These characteristics make aluminum profiles suitable for sustainable construction practices.</p>

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Hollow Profiles AA8XXX

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 Tons m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords