CC Aluminum Sheet for Embossed Anti-Skidding - Aluminum Profiles for Glass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3400 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1) Alloy | 1050, 1060,1100, 3003 3004 3105 3005 5005 5052 etc |

2) Temper | O/H12/H14/H1/H18/H32/H34/H36/H38//H111/H112/H116/H321/T6/T651/T3/T351 etc |

3) Thickness | 0.1mm to 6mm |

4) Width | 20mm to 3300mm |

5) Coil weight | 100kgs to 6 tons depends on actual requirement |

6) Core material | Aluminum alloy |

7) Coil Inner diameter | 76mm, 152mm,or as required |

2. Application of Aluminum

(1).Interior: wall cladding, ceilings, bathrooms, kitchens and balconies, shutters, doors...

(2).Exterior: wall cladding, facades, roofing, canopies, tunnels,column covers , renovations...

(3).Advertisement: display platforms, signboards, fascia, shop fronts...

3. Feature of Aluminum

*Such coil is specially designed to replace aluminum ingot, due to the high export tax of aluminum ingot, the coil has better price than ingot.

*This type of coil can fit customer's remelting furnace just like ingot, no need to make any change to the production line that was previously used for ingot. The standard coil size and weight is very suitable for the feed gate of furnace.

*This type of coil causes less material wastage than ingot when remelted.

*Our coil is made directly from ore, no need to go though the ingot making process, quality is much better than other suppliers who use ingot scrap to make coil.

Be free from Oil Stain, Dent, Inclusion, Scratches, Stain, Oxide Dicoloration, Breaks, Corrosion, Roll Marks, Dirt Streaks and other defect which will interfere with use

4. Certificate:

SGS and ROHS(if client request, paid by client), MTC(plant provided), Certificate of Origin(FORM A, FORM E, CO), Bureau Veritas and SGS (if client request, paid by client), CIQS certificate

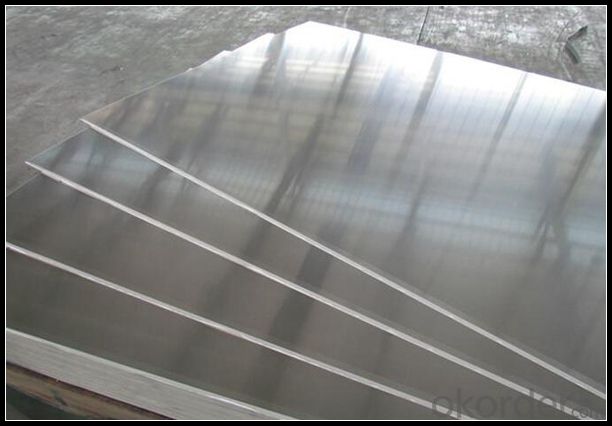

5. Image of Aluminum

6. Our Service

1. Reply your enquiry in 24 working hours. |

2. OEM, buyer design, buyer label services provided. |

3. Exclusive and unique solution can be provide to our customer by our well traned and professional engineers and staffs. |

4. We can provide free sample for your check |

5. We have the certification of ISO 9001 |

6. Timely delivery |

7. Special discount and protection of sales area provided to our distributor. |

8. Good after-sale service. |

7. FAQ

Q: What is the produce prase? |

A: Normally it would be 40days after received your deposit. |

Q: Can you provide free samples? |

A: Yes, free samples will be sent to you on freight at destination. |

Q: Can I get your latest catalogue? |

A: Yes, it will be sent to you in no time. |

Q: What is the MOQ? |

A: 3 tons |

Q: What are your payment terms? |

A: We accept L/C, D/A, D/P, T/T, West Union,etc. |

- Q: What are the manufacturers of aluminum profiles in Jiangsu and Jiangyin?

- Hello, I do not know if you have any requirements to the region, if not, you can consider the manufacturers here in Foshan?Industrial aluminum extrusion machine operation rules and precautions (looking for aluminum profiles manufacturers search: "Foshan bright silver custom")First from the process analysis:1. open aluminum extrusion machine, must ensure that equipment around and on the machine no debris, oil2. prepare the material according to the production request, and then pour into the tank according to the proportion3. check the power status and acknowledge the normal operation of the control cabinet

- Q: Are aluminum profiles suitable for use in the electronics industry?

- The electronics industry finds aluminum profiles to be a suitable option. Aluminum, being lightweight, durable, and resistant to corrosion, becomes an excellent choice for different electronic applications. Its exceptional thermal conductivity facilitates efficient dissipation of heat in electronic devices, which is crucial to avoid overheating and ensure optimal performance. Moreover, aluminum profiles can be easily customized and fabricated to fulfill specific design requirements, making them adaptable for various electronic components and enclosures. They also possess electromagnetic shielding properties, safeguarding sensitive electronic circuits from interference. All in all, aluminum profiles provide numerous advantages for the electronics industry, making them a popular and appropriate option for electronic devices and equipment.

- Q: Everybody good: please look at this section of the aluminum can not buy ready-made standard parts. If the mold needs to be opened, is it the extrusion process? About how much is the die charge?. Thank you.

- You mold two boxes connected at a relatively small, may die requirements will be much higher, I do not know whether the price will be more expensive.

- Q: What are the different packaging options available for aluminum profiles?

- There are several packaging options available for aluminum profiles, including individual poly bags, cardboard tubes, wooden crates, or pallets. These options ensure the protection and safe transportation of the aluminum profiles.

- Q: Can aluminum profiles be used in elevator or escalator systems?

- Indeed, elevator or escalator systems can incorporate aluminum profiles. These profiles possess qualities such as being lightweight, durable, and resistant to corrosion, rendering them appropriate for a range of uses, including the construction of elevator and escalator elements. Aluminum profiles can serve as the structural framework, handrails, cladding, and other components within an elevator or escalator system. Furthermore, these profiles can be effortlessly tailored and manufactured to fulfill the exact specifications of each project. The adaptability, ratio of strength to weight, and visual attractiveness of aluminum profiles establish them as a superb option for elevator and escalator systems.

- Q: Are aluminum profiles resistant to mold or mildew?

- Indeed, aluminum profiles exhibit a remarkable resistance to the growth of mold and mildew. This is due to the inherent properties of aluminum, which render it highly impervious to these unsightly invaders. In contrast to materials like wood, which are susceptible to moisture damage and consequently encourage the proliferation of mold and mildew, aluminum remains unaffected by such issues. Moreover, aluminum profiles are frequently treated with protective coatings or finishes that further bolster their resilience against the encroachment of mold and mildew. Consequently, aluminum profiles represent an ideal choice for areas that are prone to excessive humidity or moisture, such as bathrooms or kitchens, where the growth of mold and mildew is a prevalent concern.

- Q: Can aluminum profiles be used in cleanroom environments?

- Yes, aluminum profiles can be used in cleanroom environments. Aluminum is a commonly used material in cleanroom construction due to its non-porous and non-shedding properties. It is easy to clean, resistant to corrosion, and can withstand rigorous cleaning processes without compromising its structural integrity. Additionally, aluminum profiles can be easily customized and assembled to meet the specific needs and requirements of a cleanroom environment.

- Q: What are the different welding options available for aluminum profiles?

- Some of the different welding options available for aluminum profiles include tungsten inert gas (TIG) welding, metal inert gas (MIG) welding, friction stir welding, and laser welding. Each method has its own advantages and is suitable for different applications and thicknesses of aluminum profiles. TIG welding provides precise control and is commonly used for thin aluminum profiles, while MIG welding is faster and more suitable for thicker profiles. Friction stir welding is a solid-state joining process that can create high-quality welds with minimal distortion. Laser welding offers high energy density and is often used for precision welding of aluminum profiles.

- Q: Many aluminum extrusions are edge banding materials. What special advantages do they have for opening materials?.

- But in fact, the sealing material is more porous, which is a structural defect. In practice, there is no difference between the two. The opening material is not easy to seep and saves materials. Most of the materials used in the construction site are openings, and there is no problem at all. Sealing materials really do not have much merit.

- Q: How is the thickness of the base plate of the aluminum profile radiator calculated? Are there formulas for calculation?

- There should be empirical formula, the heat of the surface heat dissipation is related to thermal conductivity, thickness, temperature change, surface area. Then the best thickness is calculated by linear programming.

Send your message to us

CC Aluminum Sheet for Embossed Anti-Skidding - Aluminum Profiles for Glass

- Loading Port:

- Qingdao

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 6 m.t.

- Supply Capability:

- 3400 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords