Aluminum Extrusions Profiles Wholesale - Aluminum Corner Profile Factory Direct from China

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.1

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

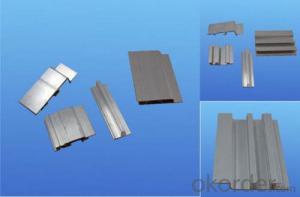

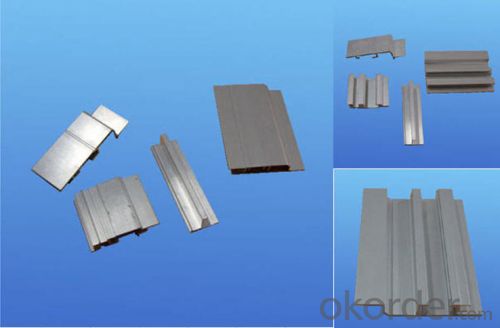

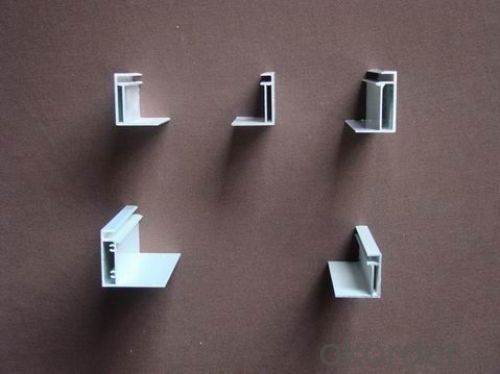

Aluminum Frame and Corner

Products Introduction of Alumium Frame and Corner

Aluminum frame is made from aluminum and minerals. It's raw matrial for window frame, window frame, and other equipment frame. It's easy for construction, cost less, service longer than other materails. The size and design can be customerized.

Advantage of Aluminum Frame and Corner

-Build FLEXIBLE equipment, window, door.

-Bolt your structure together

-Build with Aluminum MORE EASILY

-Aluminum costs LESS

-Service life is more than 10 years

-Can be customerized

Specifications of Aluminum Frame and Corner

(1) Product: Aluminium Frame;

(2) Material: Alloy 6063/6061/6005/6060, T5/T6;

(3) Finish: anodizing, powder coating, wooden, electrophoresis or any color;

(4) Size: customized, same as drawings or samples;

(5) Standard: High-quality;

(6) Characteristics: strong, stylish, durable, corrosion-resistant.

Aluminium Alloy: 6063, 6061, 6005, 6060 Thermal Treatment: T5, T6

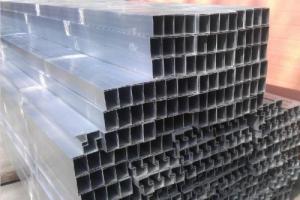

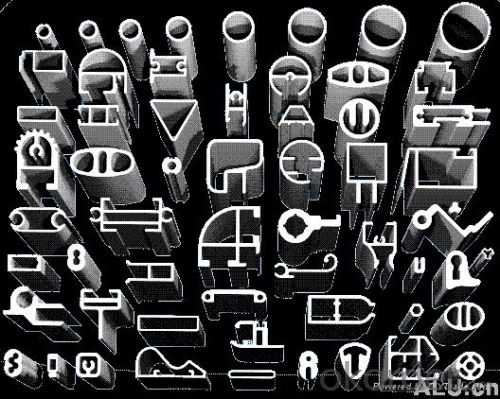

Section Shapes

I, U, T, C, Z, L, H, square, round, flat, hollow, t-slot, and other complicated shapes by custom design.

Surface treating

Mill / Anodizing (oxidation) / Sand blasting / Powder Coating / Electrophoresis / PVDFCoating / Wood effect.

Application of Frame and Corner

1) - for Window and door frames, for Wardrobe cabinet sliding doors, kitchen, for Building curtain glass walls

2) -for Fencing, Rail, Deck and Frame.

3) - for Solar panel frames, solar mounting / roofing brackets

4) - for Industry assembly lines equipment.

5) - for Heatsinks, for LED lighting.

7) - other by custom design size and dimension

FAQ

-What's your company profile?

We CNBM is the largest building material supplier of China. We are Chinese government owned corporation, which takes the 267th place in WOLD FORTUNE 500 CORPORATION. We own the largest prodcution base in North and South of China. With more than 15 warehouses and offices in different countries, our products sell very well all over the world. We have whole quality control system. We'll be your reliable partner.

-Which kind of payment do you usually support?

TT, LC at sight.

-Can you provide samples?

Yes, we provide free of charge samples, you just need to pay for the delivery.

Photos:

- Q: This question asks for methods to reduce waste associated with the production and utilization of aluminum profiles in the construction industry.

- <p>To minimize waste during the production and use of aluminum profiles in construction, one can adopt several strategies: 1. Optimize production processes to reduce material waste by using precision cutting and advanced manufacturing techniques. 2. Implement recycling programs to repurpose scrap aluminum, reducing the need for raw material extraction. 3. Design buildings with modular aluminum components that can be easily disassembled and reused in future projects. 4. Educate construction workers on proper handling and storage to prevent damage and waste. 5. Use computer-aided design (CAD) to accurately plan material requirements, minimizing offcuts. 6. Choose sustainable aluminum sources and suppliers that prioritize waste reduction. 7. Regularly audit and update production methods to incorporate new waste reduction technologies and practices.</p>

- Q: This question asks if aluminum profiles can be recycled through existing recycling programs or facilities in the user's local area.

- <p>Yes, aluminum profiles can typically be recycled using existing recycling programs or facilities. Most recycling centers accept aluminum, and aluminum profiles are no exception. However, it's always a good idea to check with your local recycling program to confirm their specific guidelines and requirements. Some facilities may require aluminum profiles to be clean and free of any non-aluminum parts before recycling. You can also look for local scrapyards or metal recycling businesses that specialize in aluminum and may offer better rates for your aluminum profiles.</p>

- Q: What are the different types of surface protection for aluminum profiles?

- There are several types of surface protection for aluminum profiles, including anodizing, powder coating, painting, and laminating. Anodizing involves creating a durable oxide layer on the surface of the aluminum, providing corrosion and wear resistance. Powder coating involves applying a dry powder to the surface and then curing it with heat, creating a tough and decorative finish. Painting involves applying liquid paint to the surface, providing both protection and aesthetic appeal. Laminating involves applying a layer of protective film or sheet to the surface, offering scratch resistance and added durability.

- Q: How do aluminum profiles contribute to sustainable building practices?

- Aluminum profiles contribute to sustainable building practices in several ways. Firstly, aluminum is a highly recyclable material, meaning that it can be reused and repurposed without losing its quality. This reduces the need for extracting and manufacturing new aluminum, reducing the overall environmental impact. Secondly, aluminum profiles are lightweight yet strong, allowing for efficient and cost-effective construction. This results in reduced energy consumption during transportation and installation. Additionally, aluminum is corrosion-resistant, ensuring durability and longevity of buildings, reducing the need for frequent replacements. Lastly, aluminum profiles can be designed to be thermally efficient, enhancing insulation and reducing energy consumption for heating and cooling. Overall, aluminum profiles promote sustainability by minimizing waste, conserving energy, and improving the lifespan of buildings.

- Q: This question asks for guidance on selecting a trustworthy supplier of aluminum profiles used in construction.

- <p>To choose a reliable supplier of aluminum profiles for building construction, consider the following: Check their industry reputation and customer reviews. Ensure they have the necessary certifications and quality standards compliance. Evaluate their product range and quality, comparing different suppliers' offerings. Assess their delivery times and reliability. Consider their after-sales service and warranty provisions. Finally, get quotes from multiple suppliers and compare prices while ensuring quality is not compromised.</p>

- Q: How do aluminum profiles perform in terms of water resistance?

- Aluminum profiles generally exhibit high water resistance due to their natural corrosion resistance and the protective oxide layer formed on their surface. This makes them highly suitable for applications exposed to water or high humidity environments. However, the performance can also depend on the specific alloy and surface treatment used.

- Q: This question asks for a list of various fasteners that are used to attach aluminum profiles to building frames.

- <p>There are several types of fasteners used to fix aluminum profiles on building frames, including: 1. Bolts and nuts, which provide a strong and secure connection. 2. Rivets, which are permanent and can't be undone once installed. 3. Screws, which are versatile and can be used in various applications. 4. Clamps, which hold profiles together without penetrating the material. 5. Adhesives, which bond profiles together chemically. 6. Welding, which joins profiles together by melting and fusing them. 7. C-clips and T-nuts, which are specialized fasteners designed for use with aluminum extrusions. The choice of fastener depends on the specific requirements of the project, such as load-bearing capacity, aesthetic considerations, and ease of assembly or disassembly.</p>

- Q: How do aluminum profiles perform in terms of creep resistance?

- Aluminum profiles generally have good creep resistance due to their high strength and stiffness. They can withstand sustained loads and high temperatures over a long period of time without significant deformation. However, the creep resistance of aluminum profiles may vary depending on the specific alloy and manufacturing process used.

- Q: What do you mean by "80868 fingers" of aluminum alloy door and window?

- Model bar, just like stainless steel 304, which is defined as the amount of metal.

- Q: This question asks about the typical applications of aluminum profiles within the field of architectural design.

- <p>Aluminum profiles are commonly used in building design for various structural and aesthetic purposes. They are utilized in curtain walls, window frames, and door systems for their strength and lightweight properties. Additionally, aluminum profiles are employed in the construction of balconies, handrails, and sunshades due to their durability and resistance to corrosion. They are also used in interior design for creating partition walls, ceiling systems, and decorative elements. The versatility of aluminum profiles allows them to be easily adapted to different architectural styles and requirements, making them a popular choice in modern construction.</p>

Send your message to us

Aluminum Extrusions Profiles Wholesale - Aluminum Corner Profile Factory Direct from China

- Loading Port:

- Guangzhou

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 0.1

- Supply Capability:

- 10000 m.t/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords