Wholesale Standard Powder Coated Aluminum Profile Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Aluminium is a relatively soft, durable, lightweight, ductileand malleablemetalwith appearance ranging from silvery to dull gray, depending on the surfaceroughness. It is nonmagnetic and does not easily ignite. A fresh film ofaluminium serves as a good reflector (approximately 92%) of visible lightand an excellent reflector (as much as 98%) of medium and far infraredradiation. The yield strength of pure aluminium is 7–11 MPa,while aluminium alloys have yield strengths ranging from200 MPa to 600 MPa. Aluminium has about one-third the densityand stiffness of steel. It is easily machined,cast, drawn and extruded.

Aluminium alloys (or aluminum alloys; see spellingdifferences) are alloysin which aluminium(Al) is the predominant metal. The typical alloying elements are copper, magnesium,manganese,silicon,tin and zinc. There are twoprincipal classifications, namely casting alloys and wrought alloys, both of which are furthersubdivided into the categories heat-treatableand non-heat-treatable. About 85% of aluminium is used for wrought products,for example rolled plate, foils and extrusions.Cast aluminium alloys yield cost-effective products due to the low meltingpoint, although they generally have lower tensile strengthsthan wrought alloys. The most important cast aluminium alloy system is Al–Si,where the high levels of silicon (4.0–13%) contribute to give good castingcharacteristics. Aluminium alloys are widely used in engineering structures andcomponents where light weight or corrosion resistance is required

Features:

Material | Alloy 6063,6061,6005or according to customer’s choice |

Temper | T3, T4, T5, T6 |

Surface | Anodize, electrophoresis, powder coating, PVDF coating, wood grain painting, matted, etc. |

Length | Coating 6.5 meters, Anodizing 6.5 meters, Mill finish 5 meters |

Application | Industrial, electrical equipment(TV set, air conditioner, refrigerator, computer), decoration,construction, transportation |

Custom Made | We can package following with customer's request. |

FAQ:

1. What is the form of payment?

Normally 30% TT, L/C at sight

2. Type of quotation?

FOB, CFR, CIF

3. Port of loading?

Shenzhen/Guangzhou port

4. Delivery time?

15-20 days after client’s deposit

- Q: Can aluminum profiles be used in modular wall systems?

- Yes, aluminum profiles can be used in modular wall systems. Aluminum profiles are lightweight, durable, and versatile, making them an ideal choice for constructing modular walls. They can be easily assembled, disassembled, and reconfigured to meet specific design requirements. Additionally, aluminum profiles offer excellent structural integrity and can accommodate various finishes, such as glass panels or cladding, enhancing the aesthetics of the modular wall system.

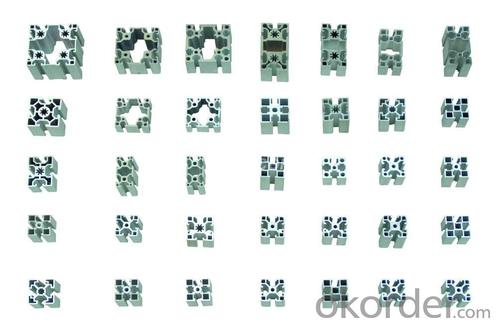

- Q: This question asks about the variety of dimensions and forms that aluminum profiles can come in.

- <p>Aluminum profiles are available in a wide range of sizes and shapes to suit various applications. Common shapes include rectangular, square, circular, and special profiles like angles, channels, and tees. Sizes can vary from thin strips to thick bars, with specific dimensions tailored to the needs of the project. The profiles can be flat, hollow, or have complex cross-sectional geometries. They are also available in different surface finishes, such as anodized, painted, or powder-coated, to enhance their appearance and durability. The selection of aluminum profiles depends on the structural requirements, design specifications, and the industry they are intended for, such as construction, automotive, or aerospace.</p>

- Q: Can aluminum profiles be bent or shaped?

- Aluminum profiles possess the capability of being bent or shaped in various ways. As a metal, aluminum is incredibly versatile and pliable, enabling it to effortlessly adopt numerous shapes and configurations. The procedure of bending or shaping aluminum profiles entails the application of heat and force to the metal, allowing it to be manipulated to one's desired form. This adaptability renders aluminum profiles exceptionally suitable for a wide array of industries, including construction, automotive, and aerospace, which demand materials that are both lightweight and durable. Moreover, aluminum profiles can also undergo extrusion, a process involving the metal being pushed through a die to create a specific shape or cross-section. All in all, the capacity to bend and shape aluminum profiles establishes them as a highly favored choice across various industries.

- Q: The original aluminum is silver, but now the market has black, yellow and green, aluminum radiator, radiator is the color what are formed by oxidation of different colors, what are the benefits of it, are used in the above types of products?

- Generally speaking, there are 2 kinds of processes for the surface treatment of aluminum profiles, which are hard anodizing coloring and color coating. Among them, hard anodic oxidation dyeing is more common.The basic process of the hard anodic oxidation dyeing is the use of additives mixed with sulfuric or chromic anodic oxidation treatment of aluminum, an aluminum oxide film layer generates high hardness aluminum surface treatment, because the alumina itself has no color and with a lot of space, so the oxygen after the general meeting of the colorant and sealing agent for the further treatment, protective properties of the oxide film has been further improved after treatment, but also can make the aluminum surface with different colors.

- Q: Are aluminum profiles suitable for historical or heritage restoration projects?

- Yes, aluminum profiles can be suitable for historical or heritage restoration projects. Aluminum is a versatile material that can be customized to match the original design and aesthetic of historical buildings. It is durable, lightweight, and resistant to corrosion, making it a practical choice for long-term preservation. Additionally, aluminum profiles offer flexibility in design and can be easily fabricated to replicate intricate details found in heritage structures.

- Q: Is it possible to recycle aluminum profiles and repurpose them for construction purposes?

- <p>Yes, aluminum profiles can be recycled and reused as building materials. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to producing new aluminum from raw materials. Recycled aluminum maintains its strength and properties, making it suitable for various construction applications. This practice not only conserves natural resources but also reduces waste and environmental impact.</p>

- Q: Can aluminum profiles be used for modular systems or frameworks?

- Yes, aluminum profiles can be used for modular systems or frameworks. Aluminum profiles are lightweight, strong, and have excellent structural integrity, making them an ideal choice for constructing modular systems or frameworks. These profiles can be easily assembled and disassembled, allowing for flexibility and adaptability in designing various structures. Additionally, aluminum profiles offer good corrosion resistance, making them suitable for both indoor and outdoor applications. They also provide a sleek and modern aesthetic appeal, making them popular in architectural and industrial design. Overall, aluminum profiles are a versatile and reliable option for creating modular systems or frameworks.

- Q: What are the color options available for aluminum profiles?

- The color options available for aluminum profiles are vast and diverse. Standard options usually include silver, bronze, and black anodized finishes. However, these profiles can also be powder-coated in a wide range of colors, allowing for customization to match any aesthetic or design preference.

- Q: This question asks for a method to determine the quantity of aluminum profiles needed for a construction project.

- <p>To calculate the amount of aluminum profiles required for a building project, follow these steps: 1. Determine the project's design and specifications to identify where aluminum profiles are needed. 2. Measure the dimensions of the areas requiring aluminum profiles (length, width, height). 3. Calculate the total linear footage needed by multiplying the dimensions. 4. Consider the profile's cross-sectional area and the project's load-bearing requirements. 5. Account for waste and additional material for joints, connections, and potential errors. 6. Consult with suppliers or use industry-standard formulas to determine the exact quantity of profiles needed. 7. Review and adjust calculations as the project progresses to ensure accuracy.</p>

- Q: Are there any limitations or drawbacks of using aluminum profiles?

- Yes, there are some limitations and drawbacks of using aluminum profiles. One limitation is its lower strength compared to other materials such as steel. Aluminum profiles may not be suitable for heavy-duty applications that require high tensile strength or load-bearing capacity. Therefore, in certain scenarios, steel or other materials may be preferred. Another drawback is that aluminum is more prone to corrosion compared to materials like stainless steel. Although aluminum profiles can be treated with protective coatings, they may still be susceptible to corrosion in harsh environments or if not properly maintained. This can affect their durability and longevity. Furthermore, aluminum profiles may have higher initial costs compared to other materials. The production and processing of aluminum can be more expensive, which can impact the overall cost of using aluminum profiles in construction or manufacturing projects. Lastly, aluminum profiles may have limitations in terms of design flexibility. While aluminum is relatively easy to shape and mold into various profiles, it may not be as versatile as some other materials. This can limit the options available for complex or intricate designs. Despite these limitations and drawbacks, aluminum profiles still offer many advantages such as lightweight construction, excellent thermal conductivity, and resistance to electrical conductivity. Therefore, it is essential to carefully consider the specific requirements and constraints of a project before deciding to use aluminum profiles.

Send your message to us

Wholesale Standard Powder Coated Aluminum Profile Extrusion

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords