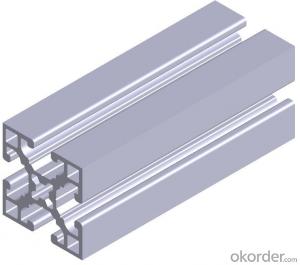

Aluminum Alloy Curtain Wall Corner Profile for Sliding Screen Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Curtain wall corner profile

1. Surface: Mill surface treatment or others.

2. Alloy: AA6063-T6 ,

3. Size:various dimensions in order to meet customer’s requirement

4. Physical Performance: Aluminium does not suffer badly from corrosion and is easy to form and finish allowing many different designs. Aluminium is used as hollow sections and is relatively flexible in bending and torsion. Hardware often has to be matched against a particular profile. Because of the hollow and complex profile cross sections achievable with aluminium it is easy to make drained and ventilated or pressure equalised windows. Aluminium is a very good conductor of heat. To meet requirements for low thermal transmission aluminium profiles are thermally broken with either a polyamide or resin element between inner and outer aluminium sections. The latest proposals for improving the thermal performance of windows will require improved thermal breaks. Aluminium is the most common frame material for stick system curtain walls, glazing screens and shop fronts. It is also commonly used as a framing system to support rainscreens.

5. Alloy advantage: The alloy temper with 6063T6 which allows this structure to maintain good formability, good weldability, high hardness, good workability and good interface characteristics. Easy processing, easy coating and good corrosion resistance, oxidation resistance.

6. Package: Each profile is wrapped by the particular paper to avoid the scratching between each profile and also prevent the moisture in the air. Outside the bundle is fixed with the four wooden boards including support board vertically and base board on horizontal level. There are steel belts outside the boards to strap and tighten.

7. Life Time: Last for 50 years

8. Standard: EN755-9 standard

- Q: What are the different bending options available for aluminum profiles?

- There are several bending options available for aluminum profiles, depending on the specific requirements and desired outcomes. Some of the common bending methods for aluminum profiles include: 1. Roll Bending: This method involves passing the aluminum profile between a series of rollers to achieve the desired bend. Roll bending is typically used for larger and thicker profiles, as it provides a gradual and consistent bend. 2. Press Bending: Press bending uses a hydraulic or mechanical press to apply force and shape the aluminum profile into the desired form. This method is suitable for both small and large profiles and can achieve various bend angles. 3. Mandrel Bending: Mandrel bending involves inserting a mandrel, which is a rod or tube, into the aluminum profile to maintain its shape during the bending process. This method ensures precise and uniform bends, making it suitable for complex shapes and tight radius bends. 4. Stretch Bending: Stretch bending applies controlled stretching forces to the aluminum profile, allowing it to flex and bend. This method is often used for profiles with large radii and gentle curves. 5. Rotary Draw Bending: Rotary draw bending utilizes a die and a rotating arm to bend the aluminum profile around a specific radius. This method is highly accurate and commonly used for precise and repeatable bends. 6. Heat Bending: Heat bending involves applying heat to the aluminum profile to soften it before bending. Once the desired bend is achieved, the profile is cooled to retain its new shape. This method is suitable for profiles with complex shapes and sharp angles. Each bending option has its advantages and limitations, and the selection depends on factors such as the profile size, shape complexity, bend angle, and required precision. Consulting with a professional or a bending specialist is recommended to determine the most appropriate bending method for specific aluminum profile applications.

- Q: How do you cut and shape aluminum profiles?

- To cut and shape aluminum profiles, you can use various methods such as sawing, milling, drilling, or using specialized cutting tools. Sawing can be done with a hacksaw, circular saw, or miter saw, while milling involves using a milling machine to remove material and create desired shapes. Drilling is commonly used to create holes in the aluminum profiles. Additionally, specialized cutting tools like shears or punches can be utilized for specific cutting requirements. It is important to select the appropriate tools and techniques based on the profile's thickness, complexity, and desired outcome. Safety precautions and appropriate protective gear should always be used when working with aluminum.

- Q: Is it possible to recycle aluminum profiles and use them again in construction projects?

- <p>Yes, aluminum profiles can be recycled and reused in construction. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to the production of new aluminum. Recycled aluminum maintains its properties, making it suitable for various construction applications. This practice not only conserves resources but also reduces waste and environmental impact.</p>

- Q: What are the aluminum packaging methods?

- Common1 each cotton covered cotton;2 each sleeve;3 coat big bag plastic sealing;4, two wire line;5, three, wrapping paper;6, outsourcing cotton (outsourcing paper).....

- Q: What are the applications of aluminum profiles?

- Due to their unique characteristics and properties, aluminum profiles have a wide range of applications in various industries. Some of the main uses of aluminum profiles are as follows: 1. In the construction industry, aluminum profiles are extensively employed for windows, doors, curtain walls, and structural components. Their excellent strength, durability, and corrosion resistance make them ideal for building purposes. 2. The automotive industry utilizes aluminum profiles to manufacture lightweight and fuel-efficient vehicles. They are used in the production of car frames, engine mounts, heat exchangers, and other structural components. 3. The aerospace industry relies on aluminum profiles for their high strength-to-weight ratio. They are used in the construction of aircraft frames, wings, fuselage, and other critical components. 4. Aluminum profiles are widely used in electrical and electronics applications. Their excellent thermal conductivity and electrical insulation properties make them suitable for manufacturing heat sinks, LED lighting fixtures, electrical enclosures, and electronic device housings. 5. The furniture industry is increasingly incorporating aluminum profiles to create lightweight and stylish furniture pieces. They are used in the production of chairs, tables, cabinets, and shelving systems, providing a modern and aesthetic appeal. 6. Aluminum profiles play a significant role in the manufacturing of industrial machinery and equipment. They are utilized in the construction of conveyor systems, assembly line structures, machine frames, and guarding systems due to their lightweight, durability, and ease of fabrication. 7. In the marine industry, aluminum profiles are commonly used for their corrosion resistance and lightweight properties. They are utilized in the construction of boat frames, masts, hulls, and other marine structures. 8. Aluminum profiles also find applications in renewable energy systems such as solar panels and wind turbines. They are used in the manufacturing of solar panel frames, wind turbine supports, and mounting structures due to their lightweight nature and corrosion resistance. Overall, aluminum profiles offer a versatile and cost-effective solution for various industries, meeting their specific requirements for strength, durability, lightweight, and corrosion resistance.

- Q: This question asks for a list of various materials that are used in the production of aluminum profiles.

- <p>Aluminum profiles are primarily made from aluminum alloys, which are composed of aluminum combined with other elements to enhance their properties. Common materials used include 6063 aluminum alloy, known for its excellent extrudability and weldability, making it ideal for a wide range of applications. 6061 aluminum alloy is also used for its high strength and good corrosion resistance, suitable for structural components. Other alloys such as 6082 and 7075 are utilized for their superior strength-to-weight ratios, often found in aerospace and automotive industries. Additionally, aluminum profiles may incorporate materials like magnesium, silicon, copper, and manganese to achieve specific mechanical properties or corrosion resistance tailored to particular applications.</p>

- Q: How do aluminum profiles perform in terms of electrical conductivity?

- Aluminum profiles have relatively low electrical conductivity compared to other metals such as copper or silver, but they still conduct electricity to some extent. They can be used for applications where moderate conductivity is required, but for high-performance electrical applications, other metals may be more suitable.

- Q: This question asks for a list of various fasteners that are used to attach aluminum profiles to building frames.

- <p>There are several types of fasteners used to fix aluminum profiles on building frames, including: 1. Bolts and nuts, which provide a strong and secure connection. 2. Rivets, which are permanent and can't be undone once installed. 3. Screws, which are versatile and can be used in various applications. 4. Clamps, which hold profiles together without penetrating the material. 5. Adhesives, which bond profiles together chemically. 6. Welding, which joins profiles together by melting and fusing them. 7. C-clips and T-nuts, which are specialized fasteners designed for use with aluminum extrusions. The choice of fastener depends on the specific requirements of the project, such as load-bearing capacity, aesthetic considerations, and ease of assembly or disassembly.</p>

- Q: Can aluminum profiles be used for access control systems?

- Yes, aluminum profiles can be used for access control systems. Aluminum profiles are commonly used in the construction of access control systems due to their durability, lightweight nature, and corrosion resistance. They provide a sturdy framework for mounting access control devices such as card readers, keypads, and biometric scanners. Additionally, aluminum profiles offer flexibility in design and can be easily customized to fit specific requirements of access control systems.

- Q: Are aluminum profiles suitable for roofing systems?

- Yes, aluminum profiles are suitable for roofing systems. Aluminum is a lightweight and durable material that offers numerous advantages for roofing applications. It is highly resistant to corrosion, making it suitable for various weather conditions and ensuring long-term performance. Aluminum profiles also have excellent thermal properties, reflecting heat and reducing energy consumption for cooling purposes. Additionally, aluminum is easy to work with, allowing for flexibility in design and installation. Overall, aluminum profiles are a popular choice for roofing systems due to their strength, longevity, and aesthetic appeal.

Send your message to us

Aluminum Alloy Curtain Wall Corner Profile for Sliding Screen Doors

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 5 m.t.

- Supply Capability:

- 10000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords