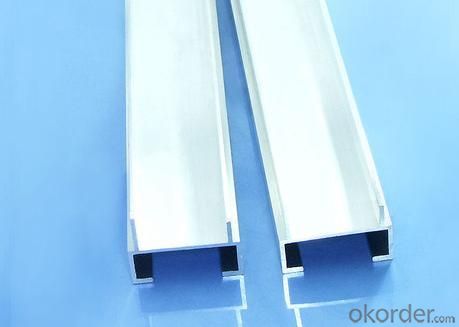

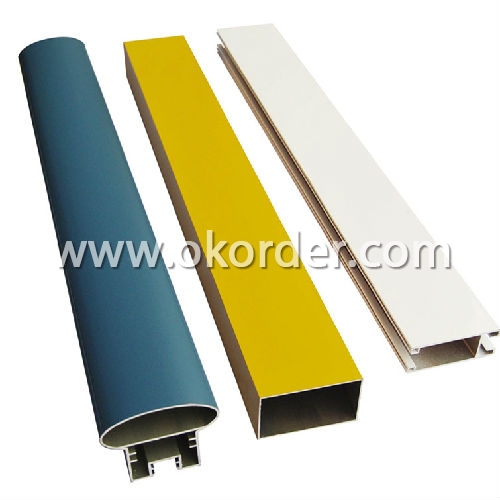

Aluminum Profiles for Door and Window

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1 Specifications of Aluminum Profiles AA1xxx

Alloy Number | 6063 6061 6060 and different aluminium alloy |

Temper | T4 T5 T6 or other special status |

Surface available | Mill finish, Anodized, Powder Coating, Wooden transfering, electrophoresis, heat insulation, PVDF, and deep processing |

Thickness: | >0.8mm |

Width: | <300mm |

Standard | GB5237.1-2008 |

Special Specification is available on customer’s requirement

2 Usage/Applications of Aluminum Profiles AA1xxx

Aluminium Profiles are widely used in construction(windows & doors,curtain wall), decoration ( flooring and tiling, kitchen) and industry ( heat sink ).

CNBM produces aluminum profiles which meets the national standard GB5237.1-2008. Our strong quality control term bring you the most-qualified products. And with state-of-the-art equipment, and the state owned company background, we have to say, you will understand why there are so many company choose CNBM to be their supplier.

3 Packaging & Delivery of Aluminum Profiles AA1xxx

Packaging:Seaworthy package, bubble plastic bag inside, anti-moisture paper wrapped outside, covered with cartons, on wooden pallets, in containers.

Shipment:the goods will be delivered in 15-30days after getting the buyer's payment.

4 Production Flow of Aluminum Profiles AA1xxx

Aluminium ingot & alloy→melting and casting→extrusion→powder coating→pouring rubber for heat insulation→checkout→packing→PVDF coating\anodizing\electrophoresis→put in products warehouse.

- Q: This question asks for methods to protect aluminum profiles from water damage during the installation and usage phases.

- <p>To prevent water damage to aluminum profiles during installation or use, follow these steps: 1. Ensure the aluminum profiles are properly sealed with a high-quality sealant to prevent water penetration. 2. Use corrosion-resistant fasteners and hardware to avoid rusting. 3. Install drainage systems to direct water away from the profiles. 4. Regularly inspect and maintain the profiles to identify and repair any damage promptly. 5. Avoid installing profiles in areas with high humidity or direct exposure to rain. 6. Use protective coatings or paints that are water-resistant and compatible with aluminum. 7. Keep the profiles clean and free from dirt or debris that can trap moisture. By following these precautions, you can significantly reduce the risk of water damage to aluminum profiles.</p>

- Q: Can aluminum profiles be used in agricultural greenhouse manufacturing?

- Yes, aluminum profiles can be used in agricultural greenhouse manufacturing. Aluminum profiles are lightweight, strong, and resistant to corrosion, making them suitable for constructing greenhouse structures. Additionally, their versatility allows for customization and easy installation of various greenhouse components.

- Q: This question asks for a method to determine the quantity of aluminum extrusions required for a particular project.

- <p>To calculate the amount of aluminum extrusions needed for a specific project, follow these steps: 1. Determine the dimensions and design of the project to understand where and how aluminum extrusions will be used. 2. Calculate the length of each extrusion piece required based on the project's structure. 3. Multiply the number of pieces by the length of each piece to get the total length of aluminum needed. 4. Consider any additional factors such as waste, tolerances, and potential design changes. 5. Consult with an aluminum supplier or use specialized software for more precise calculations, especially for complex projects. Always account for a margin of error and additional material for contingencies.</p>

- Q: What are the different packaging options for aluminum profiles?

- Aluminum profiles can be packaged in various ways to suit the specific needs and preferences of customers. Here are some common packaging options: 1. Bundling: Small profiles of the same length and shape can be bundled together using straps or bands. This option allows for easy handling and transportation. 2. Wooden crates: Larger or delicate profiles are often packed in wooden crates, which provide excellent protection during shipping. The crates can be customized to fit the profiles perfectly. 3. Cardboard tubes: Thin and lightweight profiles, such as those used in the packaging industry, can be packaged in cost-effective cardboard tubes. This option ensures lightweight transportation and storage with adequate protection. 4. Pallets: When dealing with a large volume of profiles, pallets are commonly used. The profiles are stacked and secured on the pallet using strapping or shrink wrap. Pallets allow for efficient handling using forklifts or pallet jacks. 5. Custom packaging: Customers with specific requirements can opt for custom packaging solutions. This may include foam inserts, plastic wraps, or personalized labeling. Custom packaging ensures proper protection and adherence to handling instructions. To summarize, the packaging options for aluminum profiles depend on factors such as size, fragility, and volume. Whether it's bundling, wooden crates, cardboard tubes, pallets, or custom packaging, each option offers its own benefits in terms of protection, handling, and transportation convenience.

- Q: What are the different accessories available for aluminum profiles?

- There are a wide range of accessories available for aluminum profiles that can enhance their functionality and versatility. Some of the common accessories include: 1. T-nuts: T-nuts are used to create threaded connections within aluminum profiles, allowing for easy attachment of various components such as brackets, panels, and fasteners. 2. Corner connectors: These connectors are used to join aluminum profiles at right angles, enabling the creation of sturdy and rigid structures. They come in various designs, such as external or internal corner connectors. 3. End caps: End caps are used to seal the open ends of aluminum profiles, providing a clean and finished look while also protecting against dust, debris, and potential injuries. 4. Brackets and fasteners: Brackets and fasteners are essential accessories for securing and supporting components within aluminum profiles. They come in various shapes and sizes to accommodate different applications. 5. Panel mounts: Panel mounts provide a secure and convenient way to attach panels, boards, or other flat surfaces to aluminum profiles. They can be easily adjusted or removed as needed. 6. Hinges and handles: These accessories are commonly used in applications where doors, lids, or covers need to be attached to aluminum profiles. Hinges allow for smooth opening and closing, while handles provide a comfortable grip. 7. Cable management solutions: Cable management accessories such as cable clips, cable ducts, and cable ties are available to keep wires and cables organized within aluminum profiles, ensuring a neat and professional appearance. 8. Leveling feet and casters: Leveling feet and casters are useful accessories for aluminum profile-based structures that need to be mobile or require stability on uneven surfaces. Leveling feet help adjust the height and ensure stability, while casters provide mobility. 9. LED lighting solutions: Aluminum profiles are often used for LED lighting applications, and various accessories are available to integrate lighting strips, diffusers, and connectors for a seamless and professional lighting solution. 10. Sensors and switches: Accessories like sensor mounts and switch brackets are designed to integrate sensors or switches into aluminum profiles, allowing for easy installation and integration into automation or control systems. These are just a few examples of the many accessories available for aluminum profiles. The wide range of options allows for customization and adaptation to specific needs and applications, making aluminum profiles a versatile and reliable choice for various industries and projects.

- Q: Are aluminum profiles suitable for the furniture industry?

- Yes, aluminum profiles are suitable for the furniture industry. They are lightweight, durable, and have a sleek and modern appearance. Additionally, aluminum profiles can be easily customized and shaped into various designs and sizes, making them versatile for different furniture applications. They are also resistant to corrosion and weathering, making them suitable for both indoor and outdoor furniture.

- Q: What are the advantages of using aluminum profiles in the defense industry?

- Using aluminum profiles in the defense industry offers several benefits. Firstly, they have a high strength-to-weight ratio, meaning they are strong and durable while remaining lightweight. This is crucial in the defense industry, where reducing weight is important for improving mobility and saving fuel. Secondly, aluminum profiles have exceptional corrosion resistance. This is advantageous in defense applications where equipment is exposed to harsh environments like saltwater or extreme weather. The corrosion resistance ensures the equipment remains functional and reliable for long periods, reducing maintenance needs and increasing component lifespan. Additionally, aluminum profiles are highly malleable and can be easily shaped into complex designs. This versatility allows for greater design flexibility in defense applications, creating intricate and customized components. Moreover, aluminum profiles can be easily combined with other materials like composites or steel, expanding their potential uses in the defense industry. Another advantage of aluminum profiles is their excellent thermal conductivity. Compared to other metals, aluminum has a high thermal conductivity, enabling efficient heat dissipation in defense equipment. This is crucial in applications where thermal management is critical, such as electronic systems or high-performance vehicles. Effective heat dissipation ensures the reliability and longevity of sensitive components. Lastly, aluminum is a widely available and cost-effective material. It is abundant in nature and can be easily extracted, making it readily accessible for defense manufacturing. Furthermore, its lower cost compared to metals like titanium or steel makes it an economical choice for defense applications. This allows for cost-effective production of large quantities of components without compromising quality or performance. In conclusion, the advantages of using aluminum profiles in the defense industry include their high strength-to-weight ratio, corrosion resistance, versatility in fabrication, excellent thermal conductivity, and cost-effectiveness. These characteristics make aluminum profiles an ideal choice for various defense applications, contributing to enhanced performance, durability, and cost-efficiency in this critical sector.

- Q: Is it possible to recycle aluminum profiles and repurpose them for construction purposes?

- <p>Yes, aluminum profiles can be recycled and reused as building materials. Aluminum is highly recyclable, and the recycling process requires significantly less energy compared to producing new aluminum from raw materials. Recycled aluminum maintains its strength and properties, making it suitable for various construction applications. This practice not only conserves natural resources but also reduces waste and environmental impact.</p>

- Q: Can aluminum profiles be used in the production of industrial robots?

- Indeed, industrial robots can be manufactured utilizing aluminum profiles. Aluminum, being a lightweight and long-lasting material, presents numerous benefits when constructing robotic systems. Its strength-to-weight ratio is impressively high, rendering it ideal for constructing solid and dependable robot structures. Machining aluminum profiles is a straightforward task, enabling the creation of intricate and precise designs for diverse robot components, including frames, arms, and joints. Furthermore, aluminum's resistance to corrosion proves advantageous in industrial environments where robots may encounter harsh chemicals or challenging surroundings. In summary, aluminum profiles offer a versatile and cost-effective solution for the production of industrial robots.

- Q: Are aluminum profiles suitable for automotive body panels?

- Yes, aluminum profiles are suitable for automotive body panels. Aluminum is a lightweight and durable material that has several advantages over traditional steel panels. It offers better fuel efficiency as it reduces the overall weight of the vehicle, leading to improved performance and lower emissions. Aluminum panels also have excellent corrosion resistance, which helps to prolong the lifespan of the vehicle. Moreover, aluminum is highly moldable and can be formed into complex shapes, making it suitable for creating the aerodynamic designs required in modern automotive styling. Additionally, aluminum is a recyclable material, aligning with the industry's growing focus on sustainability. However, it is important to note that aluminum panels may require specialized repair techniques compared to steel, and they can be more expensive to manufacture initially. Overall, the benefits of using aluminum profiles for automotive body panels outweigh the potential drawbacks, making them a suitable choice for modern vehicles.

1. Manufacturer Overview

| Location | Guangdong, China |

| Year Established | 2006 |

| Annual Output Value | Above US$50 Million |

| Main Markets | Mid East;Eastern Europe;North America |

| Company Certifications | ISO 9001:2000;ISO 14001:2004;OHSAS 18001 |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Nanhai Port |

| Export Percentage | 30%-50% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English;Chinese |

| b) Factory Information | |

| Factory Size: | Above 100,000 square meters |

| No. of Production Lines | Above 10 |

| Contract Manufacturing | OEM Service Offered;Design Service Offered |

| Product Price Range | Average |

Send your message to us

Aluminum Profiles for Door and Window

- Loading Port:

- ShenZhen

- Payment Terms:

- TT or LC

- Min Order Qty:

- 10MT m.t.

- Supply Capability:

- 1000 Tons Per Month m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords