Swing Check Valve Wafer Type Double Disc DN 125 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

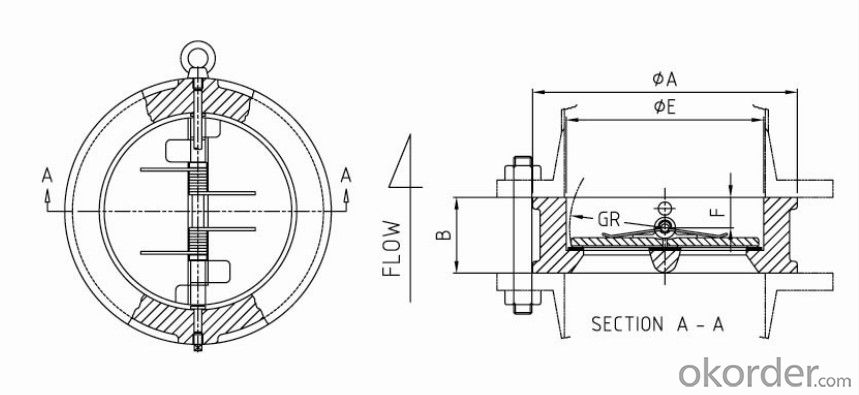

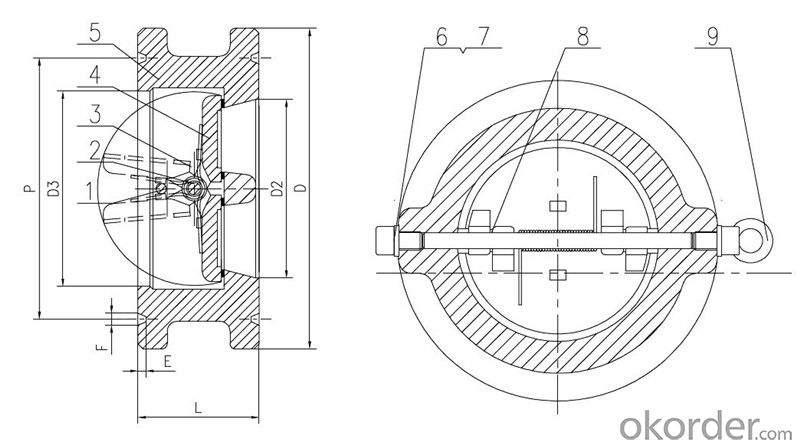

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: How would your car run if u did not have one on it? Do u really need to have a pcv valve? I have a 1994 Ford Econoline

- Yes the car would run but run very bad.. The pcv valve stands for positive crankcase ventilation If bad or missing you will have a very, very bad vacuum leak.. simple to replace change it cost is chep enough for a chance....

- Q: When I flush the toilet it flushes just fine, but it doesn't fill again. You have to close the wall valve and then open it up again to fill the tank. Is this a problem with the valve or the internals of the tank? Thanks

- Check your fill valve (inside the tank) first. If it appears to be working properly, turn the water off outside the house, drain the tank, take the filler tube ( from the valve to the bottom of the tank on the outside) loose at the valve. Remove the valve and inspect for obstructions, such as calcium and or lime deposits. You may need to replace the valve as they will occasionally wash out over time. Reverse this process to put everything back together, and be sure to wrap the male threads on the supply line (pipe sticking out of the wall) with teflon tape.

- Q: eventually needed mitrial valve replacement or Valvuloplasty? It is also sometimes called Acquired Valve Disease, Aortic Valve Disease or Mirtral Valve Disease. Any information would be very helpful. I was not born with this condition if that helps at all.

- The aortic valves and mitral valves are 2 separate valves. The aortic is the valve that leads to the pipe supplying the body and the mitral valve supplies blood from left atrium to left ventricle. Both can become thickened, making it difficult for blood to get through. You normally will have annual or bi-annual assessment of the valve using an echo and only if it is severe or causing symptoms would surgery be considered. A valvuloplasty involves inflating a balloon to split the mitral valve - this is usually performed in patients who have previously had rheumatic fever as a child and whose valve is fused at the edges symmetrically. In exterme cases a valve replacement can be performed where a mechanical or tissue valve replaces the diseased valve.

- Q: Is it possible that if you never adjust valves the engine could lose a lot of compression? 1990 Suzuki VX800, 19,000 miles on the clock. No idea if it has ever had the valves adjusted, only got it 3,000 miles and 6 months ago. It is now not running and after a compression test, has 90 psi in the rear and 150 psi in the front cylinder. Don't really have the time yet for a leak down test. Could the exhaust valves be the cause of the low compression? thanks.

- Yeah, valves should be adjusted from time to time, both intake and exhaust, they are the two biggest areas of the compression system that would cause low compression. That old of bike probably needs a good 'go-thru' to see what's happening, the leak-down is your best bet at that happening.

- Q: Water is seeping up around relief valve threads. Tried tightening but could not get it any tighter.

- Shut off the cold water supply to the water heater and also shut the gas supply or the heater control. Drain the water heater (this will drain all your house hot water as well). Open a hot water sink valve to let air enter. Drain the water until the water is lower than the threads. Cut or unsolder the joints needed to remove the threaded fitting. Remove the fitting, and bring it to a local plumbing supply house and get a new one. Install the new one with teflon tape. Shut the sink hot valve. Open the cold water supply valve on the water heater slowly. Check for any leaks. If its leaking, start over. If not resolder the copper joints together, and remember to purge the air through your sink again. Or just call a plumber or an HVAC company.

- Q: Hi, I am a junior in high school and I play the trumpet. For the past week or so my 1st valve has been odd. It gets stuck badly when it hits all the way to the bottom, and I can't seem to get it to stop. Normally when valves are sticky I just use some valve oil and it helps a lot. But it doesn't seem to work this time. It is a Bach if that helps. I think there are other types of valves so I'll say that there is a spring inside from like the middle to top. If you could help me out that would be great! Thanks =)

- PING ! You probably have a minute dent in the valve casing that the eye cannot see.. A repairman will buff it out . Meanwhile it is abrading the valve ( like a car cylinder ) so make haste to the repair shop.

- Q: I have a 03 civic ex with 96k how important is it that I do a valve adjustment. The engine runs smooth.

- the factory maintenance manual calls for the valves to be checked and adjusted if necessary every 110,000. unless they're noisy (loud tapping) they probably don't require adjustment. The older Civics were very sensitive to the valve adjustment but the 2003 won't give you any problems if the valves aren't noisy. that being said, if you notice a decrease in performance or fuel economy around that mileage it won't hurt to get them checked and adjusted. hope that helps

- Q: Can a clogged EGR regulator valve cause my car to stall out and die when it's idling at red lights?If I give it a little has it wakes the car up and keeps it from dying.One mechanic told me it was clogged up and that it can cause that issue. My boss says there's no way that's the problem... I say we've fixed cleaned or replaced just about everything else...Is this true or is the mechanic just trying to pocket a bit more $$??

- Egr Regulator

- Q: is there any way to buy refills for empty valve oil bottles, such as holton or al cass

- Refills? okorder they are horrible!

- Q: I own a 1982 Pontiac Firebird base model which has recently started leaking oil from its Proportioning Valve. I have looked all over the internet for a replacement, and it turns out GM has discontinued the part. Now im faced with difficult and risky task of attempting to fix it, or turn it over to a repair shop as a last resort. The valve seems to leak out of a small circle with a hole the size of a needle inside which was covered by a rubber gasket. I have no clue what this does, and how to repair it.

- The okorder /

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 125 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords