Swing Check Valve Wafer Type Double Disc DN 400 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

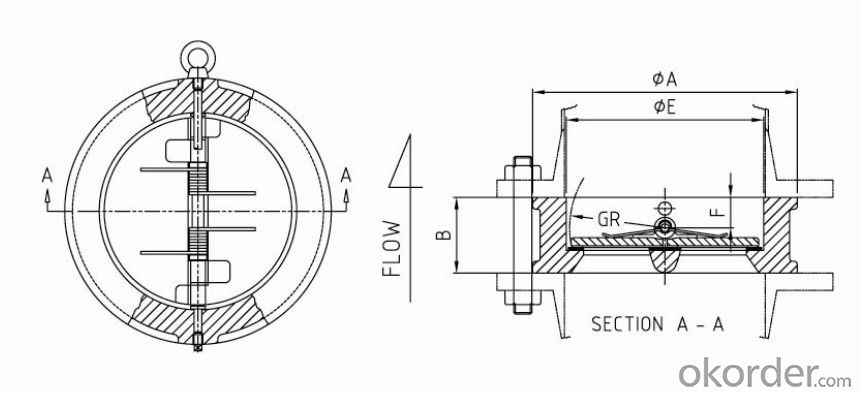

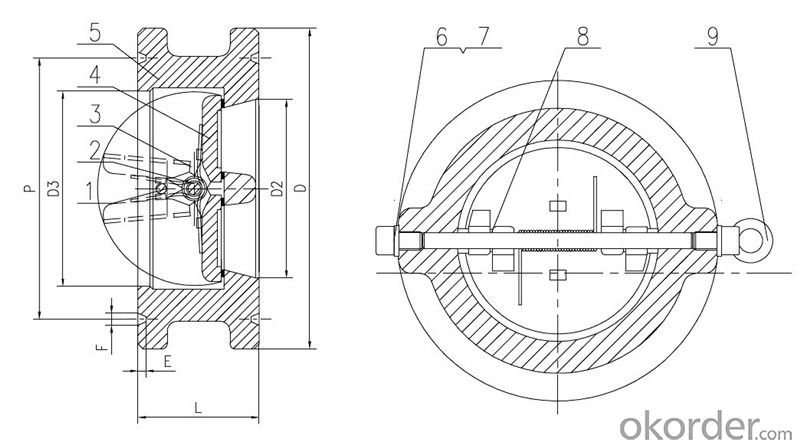

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: I play the trumpet and I took it home for Christmas Break. On Friday I am playing Amazing Grace at Church for New Years Eve, but the problem is my valves on my Trumpet is sticking and I don't have any valve oil for it. Is there any other oil that I can use for the Valves? It will be really great! Thanks :)

- valve okorder /... its simply the best

- Q: I'm at school reading a mag and all the internet is blocked except yahoo. So i'm trying to figure out what the diff is between 3 angle versus 5 angle valve jobs.

- The object of the valve angles is to produce a smooth transition to help air flow. So a 5 angle valve job is done to make a series of angles that are closer to a even radius or even parabolic. For street use, you not see that much difference. But when you are at the top levels of competition that little bit might be the difference between an also ran and a winner (read winnings).

- Q: im having trouble locating the pcv valve on my 1979 oldsmobile. i have a 305 engine. i need to replace it asap, so any help would be appreciated. thanks in advance to all feedback.

- look on the valve covers.it will be at one end with a hose running to the carb.

- Q: okay so i recently brought a trumpet and the valve keys were getting stuck. i used the valve oil and it worked. but then when i put the valve key back in and tried blowing through no sound came out. i think it's because i didnt put it back in right. now my question is how do i put it in right? i tried everything but it's still not making a sound. thanks,

- Unscrew the the valve cap on the appropriate under the button. attempt to softly pull the valve out. you may would desire to artwork it back and forth till it loosens up you may upload some oil around the the sting of the valve cylinder. as quickly as you have all 3 valves out sparkling each of the particles off of the valve, you ought to use an sos pad to get dissimilar the heaver stuff off. Wipe each factor off with slightly of lighter fluid and a sparkling rag. sparkling the valve bores including your snake. Stuff a rag down each hollow to get the stuff the snake loosened up. Reoil the valves and the cylinders and reassemble.

- Q: where is the heater control valve on a 1996 volkswagen passat

- There is no Heater Control Valve. Coolant circulates through the heater core continuously. Air flow is directed through the heater core/ac evaporator in the air distribution box under the dash as required by user input. If you have no heat, there are a couple of things that could be wrong. A bad water pump, plugged up heater core, bad blend door/cable, bad Climatronic control head, or a bad actuator/motor. So, what's your question? What is the car doing/not doing that you think it should/should not do?

- Q: Hi guys, my parents had me install a new faucet in their kitchen sink. It works great and everything, but after the install the hot water pressure basically decreased greatly. The cold water pressure is fine, but I believe after I had turned off the hot water at the shutoff valve, something in the valve got messed up and is blocking the water supply.

- Copper pipes are usually soldered. You might want to call a plumber for this.

- Q: and describe the direction and type of blood (oxygenated ot nonoxygenated) that flows through this valve.

- Mitral valve has two cusps. It is located between the left atrium and the left ventricle , oxygenated blood comes from the lungs by pulmonary veins and drains into the left atrium then the left atrium pumps this oxygenated blood through the mitral valve into the left ventricle. After that the left ventricle contracts pumping the blood through the aortic valve to the aorta..

- Q: My boyfriend is getting mitral valve replacement surgery soon, he is getting a mechanical valve put in.Has anyone had this surgery done? What are the risks. Anything else need to know about this surgery that is important. Im just worried about the surgery wanting to know as much as I can to be prepared. thank you

- Haven't had it done before but: It's a pretty involved procedure. Patient is put under general anesthesia and is usually on the cardiopulmonary bypass machine (heart-lung machine) since you can't really replace a heart valve if the heart is beating. mortality for full valve replacement according to wiki is 6-8 percent, prob less than 5% for young healthy patients. Recently, many people have been doing the procedure laparoscopically. Patients are put into the surgical ICU for typically 1-2 days after the surgery. You can be discharged about a week after. Obviously there's risks, this is a very involved and definitely not a simple procedure. However, the cardiothoracic surgeons do these procedures every day for their entire lives-they're very skilled and qualified. good luck!

- Q: I have a rainbird Sprinkler system. One of the zones the sprinklers do not pop up. Someone said maybe the valve is stuck closed from the winter. How do you open and close the valve manually to loosen it back up. and where would this valve be located in the little green junction box near where the zone starts????

- they dont really stick from the winter. i would say if the valve has a problem the diaphram needs replacing on the inside of it. ( all you have to do is find the same kind of valve and take the old parts out of the valve and replace them, the top, and the solenoid with the new valve's parts. they can be anywhere in your yard. ive even found the valve boxes buried under bushes. some installers don't put them in boxes, they just bury the valves. if you know where any of the green boxes are open the lids and see what's inside. sometimes more than one valve will be in a box. turn the solenoid on the valve. ( this will be the peice that the wire are connected to on the valve. dont turn the solenoid too much or it will come out. just a 1/4 to 1/2 a turn or so maybe a little more or less. and when you find the valve that turns on the zone 8 that is not working that is the valve for that section. you may even be able to hear the valve trying to come on when the timer shows it is running. if not, then check for power at the valve. if no power. there is a short, bad connection, or bad module in the timer. if power- replace just the solenoid first. if that doesnt work rebuild the valve. if you have no luck finding the box with zone 8 in it then try a few tips. get a screwdriver and poke around where some other valve boxes are. they may be close together. use a wire locator or hire a professional to locate the valve and show you how to repair it. to manually open and close the valve- open upthe solenoid like i said. or use the bleeder if the valve has one.

- Q: I want to find a cheap valve that will let me take a breath in from one place then exhale through a tube going out so that i can attach an airbag to the breathing end and make a little diving lung.

- What your looking for is a check valve. Home Depot Be careful, very careful!

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 400 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords