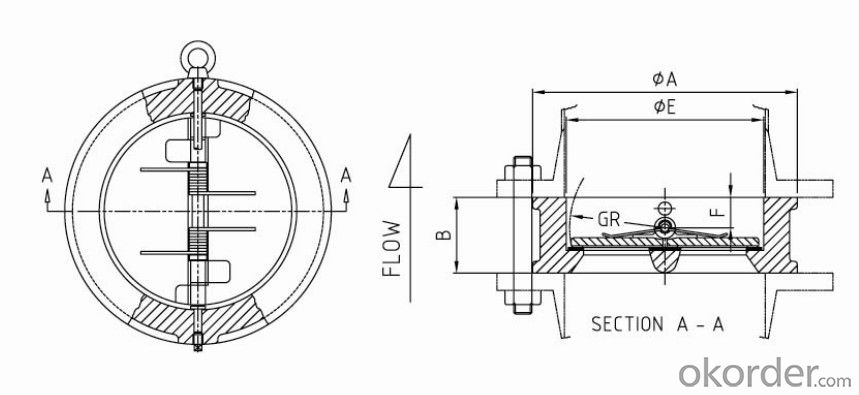

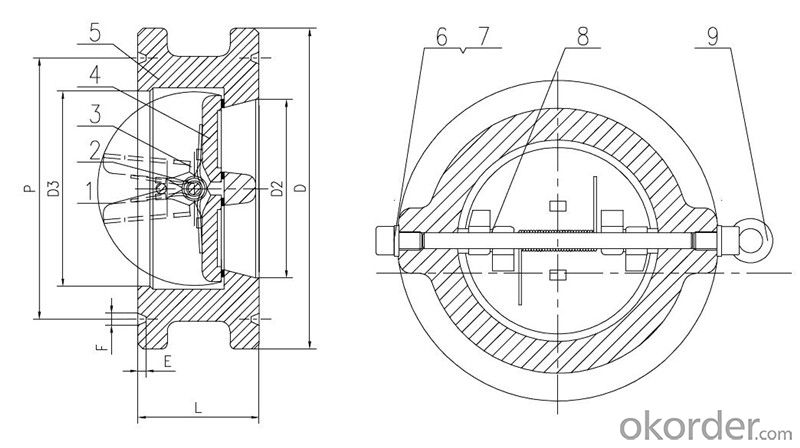

Swing Check Valve Wafer Type Double Disc DN 150 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: I have a 1997 Toyota Corolla. My check engine light has been on. I tried to get my car smogged and it failed. I then got an oil/air filter change and just yesterday I replaced the EGR valve which was the result given after 2 diagnostic tests. The mechanic gave me my car and the check engine light was off, I've only driven about 5miles and the light is back on. I have to pass smog asap to register my vehicle. I plan on calling the mechanic back and telling him the light is on, but could it just be a sensor?

- it could be a sensor ! the EGR code probably showed up because a sensor was interfering with the valve !

- Q: 1998 Ford Crown Victoria LX 4.6L Use 89 Octane BP, Shell, Chevron gas. When the engine is under stress(acceleration or going up incline) the engine sounds like the valves are chattering. I can increase the rpm's and the chattering goes away. Had the same problem with 95 Thunderbird 4.6 and have heard other ford cars going down the road with this problem. Air leak? Don't really want to use higher octane due to gas prices and possible engine damage. Also, in the thunderbird, i used a bottle of octane boost and the next day a valve spring broke. Was the octane boost a possible cause?

- it is not valve chatter, it is called Pinging, it is a fairly common problem, what it is caused by is hot spots in the engine, or by overly advanced spark timing, i would check your base timing, perhaps even back it off a degree or two, i would also run a bottle of marvel mystery oil, or gm top engine cleaner through a vacuum line to burn out the crud that has built up, the sum total of these repairs: about 15 bucks, the savings: your engine! as for your t-bird, it was the pinging that broke the valve spring, not the tank of hi octane. hope this helps

- Q: Is it supposed to go on or only in cases when the power goes out??? I bought this pump and the directions are horrible!!! There isn't room for both the air stone and the check valve!! How does this stupid thing work???

- Keep okorder /

- Q: My mom just went to DR and will have open heart next Thursday for removal of anyerisum. She was told she has 2 heart valves instead of four. What does this mean? Is it normal?

- Your mom probably has a Bicuspid aortic valve, that she was born with.. it means that the valve between her heart and the aorta has two valve leaflets instead of the usual three valve leaflets (not four) in normal people. Bicuspid aortic valve is caused by fusion of two of the three leaflets. It's a fairly common congenital condition, and is associated with a risk of aortic aneurysm (a weakening of the wall of the blood vessel which then causes ballooning of the vessel wall)...usually of the ascending aorta. All the best for her safe recovery.

- Q: hi friends i want to know about the calibration technque of foundation fieldbus based control valve by a analog source

- * okorder moreinfo

- Q: Hi all,My 1995 nissan altima (122k on the odometer) stalled for a few minutes this morning. I noticed that one of the sparkplug holes ( where the cable from the distributer connects to the spark plug) is sorrounded by oil. I cleaned it out and it got filled with oil again. luckily for me, and by god's grace it somehow started normally and i drove home. I am sure its the valve gasket. There is not much oil leakage, the oil level is fine.I need to know if its going to damage my engine if I ignored the problem for 3-4days.Thanks.

- The part itself is less than $100. It's a little rubber gasket that goes inbetween the valve cover and the engine block to make a tight seal between the middle and top of the engine. Depending on which engine you have (the 4 or the V-6), it can be a VERY simple fix with about an hour's labor because the valve cover is on top. However, some (very few) cars require you to remove the motor to get to the cover. If this is the case, 7 hours seems about right.

- Q: 1. Why is there an exaust valve. Isnt it only a port. Where do the gases that go into the exaust valve go?2. How does air enter the intake valve. If you look at a push rod diagram, you cant see where the air is enteringCan someone explain to me the valve concept

- The camshaft is turned by the crank shaft and is in time with it. the cam shaft either pushes the valves open and closed or pushes on lifters or pushrods that drive the rocker assemblies that move the valves. On a two cycle engine yes under most circumstances the exhaust valve is only a port. On a 4 cycle engine like on a vehicle it has exhaust and intake valves. When the piston is on the exhaust stroke the exhaust valve is pushed open, the piston comes up and pushes the exhaust gas out through the open valve, near the top of the piston stroke the intake valve begins to open as well and for a very brief moment both valves are open this is known as valve overlap. This allows incoming air to help expel the burnt exhaust gas. The exhaust gas goes out through the exhaust port through the exhaust piping and into the air. When an engine is running or cranking (pistons moving) it creates a natural vacuum which draws in air, when the intake valves open air is drawn into the combustion chamber pretty simple. Then the air is mixed with fuel vapor and when the piston comes up on the compression stroke the spark plug fires and the air fuel mix burns and drives the piston down. The valves allow the engine (AKA some call it an air pump) to work and pump air. Without them the pistons would do nothing absolutely nothing.

- Q: Can anyone tell me what to do if i know that I have the type of valve stem that was recalled TR413chrome?? Will they replace them for free since they are a recall or do I have to dish out some more $$ to fix the problem??? The company that sold them to me is in Florida (Wheelmax) and I am in Mass. Not sure what to do to avoid having to pay out more $$ to have them replaced...any help is greatly appreciated

- The recalled valve stems were sold under the Dill brand name - it should say Dill on the package if you have extras. If you go to the link provided above they will have additional information. This is a VOLUNTARY recall being performed by Dill, the American distributor for this particular line of Chinese made valve stems. All roads for the recall therefore lead to Dill.

- Q: im 28yrs old with two babies.in my heart two valves are very tight and leaking too,im going for a transplanting them in august.If there is anybody who got this problem solved please share.Thanks in advance.

- Usually with an artificial valve, you'll need to be on a blood thinner for the rest of your life. If they use a natural valve, you usually won't need the blood thinner - perhaps you will for a little while, but not permanently. You can request a natural valve, but the surgeon doesn't know what size/shape of valve you need until he actually opens you up and sees what he's working with. He has an idea, based on the x-rays and MRIs you've had done, but he won't know for sure until he actually see it. So the surgeons are going to request that the Organ Procurement Department to thaw out two or three valves, depending on what they see in the tests. You can't just keep thawing out valaves, testing them, and then refreezing them if they aren't what you are looking for, so if they turn out to not be a good fit, he's going to turn to an artificial valve. So you could request a natural valve, but because of the shape of the gap that he needs to fill, you may have to have an artificial valve. Blood thinners scare people, and your friends will tell you horror stories about how their uncle's cousin's Nephew cut his arm and bled to death because he was on a blood thinner! That could happen, but it is very rare. What does happen is that you will have to go to your doctor once a month and have a blood test, and if your blood is too thin, you need to ease off on the blood thinning medication. Or if it is too thick, you need to take more. If you're blood is too thin, you'll bruise more easily - which might be embarrassing if the bruise can be seen. Blood thinners aren't as dangerous as they make them out to be, but they can be inconvenient!

- Q: My husband just found out that one of the heart valves is 100% blocked and the other 3 are 90% or more blocked . He is 78 years old he Is nearly non mobile. What kind of treatment would you suggest?

- A heart valve can't be 100% blocked. The heart simply couldn't function. On the other hand, coronary arteries can be blocked as you described. Normally, 4 vessel disease is treated with bypass surgery. In a high risk patient, angioplasty might be an option. However, if he is not having cardiac symptoms , or if he is thought to be TOO high risk, the option is medical treatment. Sit down for a talk with his cardiologist.

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 150 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords