Swing Check Valve Wafer Type Double Disc DN 250 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

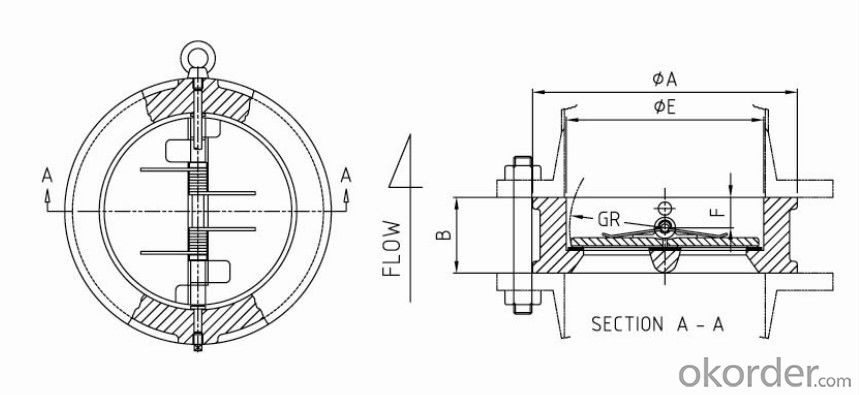

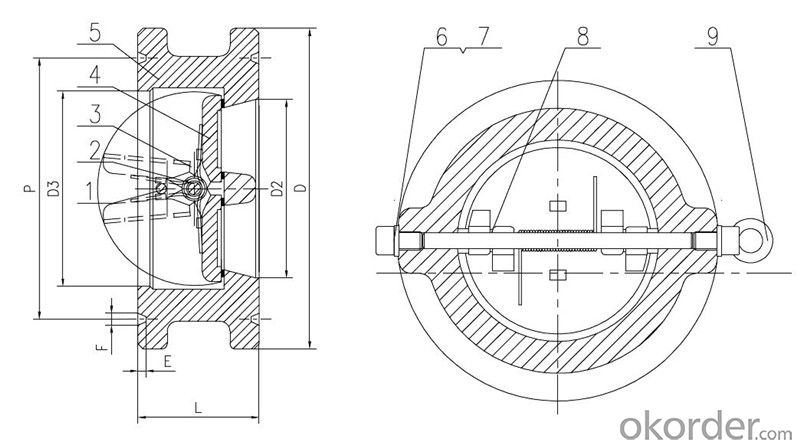

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: My fill valve in my toilet is Korky brand and when I take off the cover to the fill valve it shoots water straight up. Is there a way to fix this or do I just have to replace the fill valve.

- Why are you removing the *cover* on the fill valve? That thing was never meant to come off. I hate to say it, but I think you just destroyed your valve. Go buy a new one, they are cheap and unless they went through a redesign since you bought the last one, the seating tube coming into the tank doesn't even need to be changed. Lefty loosey the damaged valve while putting slight pressure in the downward direction and it will pop out. Just install the new one and don't forget the overflow tube connection. Throw the rest of the stuff away, you won't be needing it (if for some reason in the future you do need it you will never find it again anyway).

- Q: what is the average cost to replace a valve core on a car? also can any car shop do it or do i have to go to a conrads etc.

- You can do it yourself very cheaply. All you need to do is go to Walmart or a Auto parts store and get four valve cores and a valve core remover, then go to a gas station the has a air compressor. Remove the valve cores and put the new ones in, you don't have to let all the air out Just put the new valve core in and air the tire back up. I would check the old valve cores before I changed them or have them changed by mixing water and soap together and put in on the top of the valve core, if it bubbles then you need to replace them, if it doesn't bubble someone is just try to scam you.

- Q: i have a 05 kx250f, new valves recently,will pop start, idle runs high, has compresion, new kckstarter gear but it wont kickstart. someone said the valves need to be shimmed.anybody have any ideals? thanks.

- Who okorder /

- Q: Hi, I just got my 20 gallon freshwater aquarium yesterday and set it up today with the filter,water, pump,etc... I bought an AquaCulture 20-60 gallon double outlet air pump and didnt realize it had two valves. I only need to use one though ...what should I do??p.s. The bubbler thing that lets the bubbles out is a rectangle and its long but it isnt working in the middle of it...? would that be because of the double valve?p.p.s. the pump came with two check valves.Thanks, Sarah

- You only need to use the one valve, each valve will do 10-30 gallons so you'll be fine. As to the bubbler problem (sounds like a bubble brick to me, so that's what I'll call it), it's most likely uneven. If the brick isn't level it won't let out as much air in the right places. If leveling it doesn't work try adjust how much air goes into it, but the double valve won't be the problem for this. It came with two check valves for the two outlets, you only need to use one.

- Q: compare the structure of the tricuspid valve with that of the pulmonary valve??please help me

- Structure Of Pulmonary Valve

- Q: what are the factors should be know to select a control valve for specified application

- nan

- Q: how do i adjust the valve lash my book sys to torque to 136 in lbs but my wrench is only in ft lbs

- valve lash is a small gap between the rocker arm and the valve stem as the engine heats up the gap gets tighter due to expansion of valve train parts. To set the lash correctly find the gap that is recommended and use a feeler gauge to set. loosen the jam nut that holds the adjustable screw and set the screw to point where the guage has a slight drag on it. all this is done at the rocker arm and takes practice to get the feel of it. This must be done while the valves ARE CLOSED and the engine rotated to the correct position for that cylinder. Once the gap is set using the feeler guage, hold the adjustable screw still and tighten the jamb nut to the in./lbs. speced. In./lbs are a smaller value than ft/lbs. Find a torque wrench that has the smaller increments. If your not sure, find someone who HAS done this before and get them to assist you. Again, it must be done with the engine rotated to the correct spot. Usually around TDC for that cylinder being adjusted. Once set, test again with the feeler guage and see if the lash changed during the tightening of the jamb nut. If so, set again till lash has a slight drag. This means that you can slide the feeler guage in the gap and its not to loose nor to tight

- Q: I just got my trumpet today.And its playing fine.Now its not playing.When i play im blowing air into it but its not going through.Its like im trying to blow air through solid meatel.and everytime in blow into it.The slide with the ring on it (sorry i just got the trumpet,im not really sure what the parts are) it keeps falling off.Its like its waay too loose.Help please

- umm i'm not sure, cuz i play the clarinet but try tighning the mouth peciec and make sure your forming your lips right. then go to the place you bought it or you local music store to find out what's wrong. good luck and Merry Christmas!

- Q: Do most V6's have 24 valves? What are they for? (brief description would be fine)

- Valves in an engine have two purposes. There is a set of valves to let the air/fuel mixture IN to the engine cylinders. Those valves then close, sealing the gas in for combustion. Once the fuel has burned, the outlet valves open and let the spent fumes out through the exhaust. Cars and trucks usually have 2-4 valves per cylinder. So, in a V6 with 6 cylinders, there could be anywhere from 12 valves to 24 valves. More valves typically mean that the engine can produce more power and be more efficient.

- Q: 1998 camaro3.8L v6sometimes when i start the car, it makes this loud ticking noise that goes with the RPMIm pretty sure its the valve, anyone know how to fix it, and how much it might cost?

- This Site Might Help You. RE: How do fix a stuck valve? 1998 camaro 3.8L v6 sometimes when i start the car, it makes this loud ticking noise that goes with the RPM Im pretty sure its the valve, anyone know how to fix it, and how much it might cost?

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 250 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords