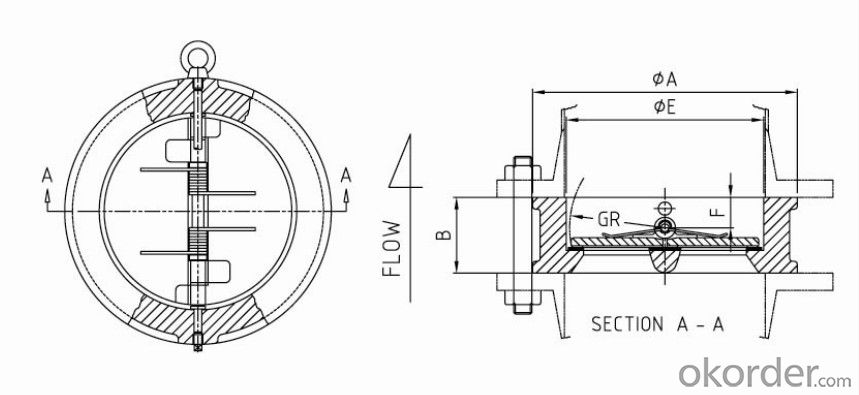

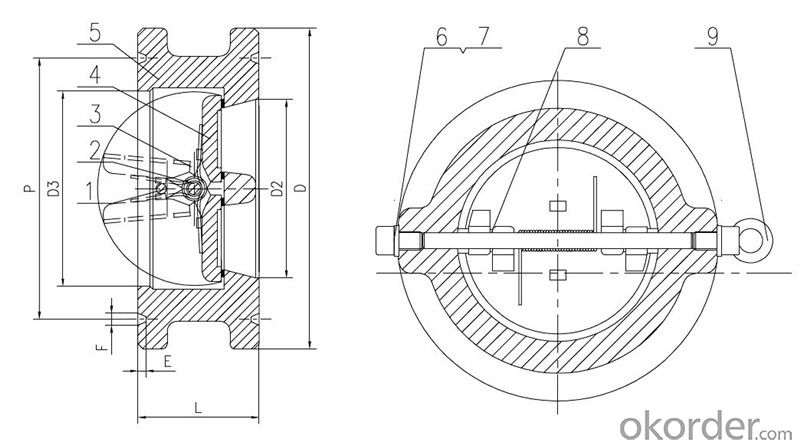

Swing Check Valve Wafer Type Double Disc DN 500 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Products Description of Swing Check Valve

Check valves are used in pipes under pressures between PN1.6~16.0MPa(Class150~2500Lb), working temperatures-196~600℃, They are used in industries include oil, chemistry, pharmaceutical, fertilizer, and power gene-ration to prevent the backward flux of the media.

The main structure features of Swing Check Valve:

1、The products feature a reasonable structure, reliable seal, good performance and nice modeling.

2、Either soft or hard seal can be selected for the product upon different working conditions.The sealing face is built up with Co-based

carbide alloy, leaving a better wearability, corrosion and scrap resistance and a longer duration.

3、Small opening pressure, the disc can be opened fully with a very small pressure differential.

4、Inside-set bolt-bearing structure reduces leakage and reliable use.

5、PN≥16.0Mpa (class1500), the middle cavity uses a self-tightening sealing structure to have the sealing performance reinforced along

with the pressure rise so as to ensure the sealing performance.

6、Different parts materials and different sizes for flange, butt-welding are available for sensible combination according to different working facts and customers' requirements.

Parameter of Swing Check Valve:

Standard Criteria | GB customize |

Pressure Rating | 1 Mpa 1.6 Mpa 2.5 Mpa 4 Mpa 6.4 Mpa 10 Mpa 16 Mpa customize |

Valve Size | 50 mm 65 mm 80 mm 100 mm 125 mm 150 mm 200 mm 250 mm 300 mm 350 mm 400 mm 450 mm 500 mm 600 mm customi |

Actuator | Automatic customize |

Connection | Wafer customize |

Medium | Oil Steam Water customize |

Medium Temperature | -196~600℃ customize |

Structural style | Swing double-clack structure customize |

Application Fields | Agriculture Electricity Medical Petrochemical customize |

1-Body Material | CF3 CF8C CF8 WCB CF8M CF3M customize |

2-Disc | CF3 CF3M WCB CF8 CF8M CF8C customize |

3-Pivot | 1Cr13 1Cr18Ni9Ti 0Cr18Ni12Mo2Ti 2Cr13 customize |

4-Spring | 60Si2Mn 1Cr18Ni9Ti 4Cr13 0Cr18Ni12Mo2Ti customize |

Design Standard | GB/T 12224 customize |

Connection Standard | GB/T 9113 HG 20592 JB/T 79 customize |

Test Standard | JB/T 9092-1999 customize |

Face to Face | GB/T 15188.2-1994 customize |

Images of Swing Check Valve:

FAQ of Swing Check Valve:

Q1:I can’t find the type of steel check valve which I need. what can I do?

The chart above only lists out some common composition of steel check valve parts.We may provide other different parts material composition according to the customer's request or the actual valve working condition.

Q2:Which certification do your products pass?

Our products are in accordance with ISO 9001、ISO 14001、API 6A、API 6D、TS CE、API607/6FA/BS6755.

Q3:How can I place an order?

The only one thing you should do is to tell us the sepecification about type 、quantity and mode of transportation, then we will send you quotation within 24 hours.

- Q: i want to know where we must use swing check valve and where we must use lift check valve in petrochemical companies. what are the differences ? are they different from the appearance? how can we distinguish between them visually?

- microscopic intervension

- Q: We have a 2008 grizzly 700...Lately when we run the 4-wheeler there is a ticking like noise (as is something were loose). I have been told by a few people that it sounds like the valves need adjusting. Does that sound like what it is? Will it cause any damage to the 4-wheeler if we ride it before we get a chance to adjust the valves?

- They are correct. Well almost. The Rockers are what can be adjusted. They are too far away from the valve and are starting to hammer on them instead of just moving them. You will not cause immediate damage by riding it but you could wear out the rocker completely and drop a valve into the engine which would be very costly. Best to get it repaired soon. Make sure they install new rockers and springs. The main cause for this is poor oil maintenance or poor grade of oil being used. Always use a GOOD synthetic oil and your motor will last 10 times as long

- Q: I have a 2005 Dodge Durango and had problems with stalling. I took it into the dealer with warranty on it. They said the ECG Valve is busted and its unsafe to drive. Can you guys tell me what the function of this part is?

- There's no such thing as an ECG valve on any automobile. You're probably referring to the EGR (Exhaust Gas Recirculation) valve. It's purpose is to pipe a little bit of the exhaust gases back into your cylinders at higher RPMs to both promote cleaner emissions and to cool down the combustion chambers to help prevent knocking and pinging. However, in time an EGR valve can eventually get clogged with carbon which can cause it to get stuck open, which would cause an excessively lean condition during idle and can cause the car to stall. It then needs to be either cleaned (with plenty of carburetor cleaner spray) or replaced. I generally wouldn't say that a defective EGR would make a car unsafe, unless perhaps there's a big crack in it and exhaust gases (carbon monoxide) are leaking into the engine compartment/vents. I would, though, take a little extra care when crossing railroad tracks or turning in front of fast-moving traffic. Stalling there could possibly turn you into a coroner's curiosity.

- Q: I have a 2000 Ford Explorer sport(2wd). I live in the Fort worth,Tx area. What would be a resonable price to have this valve changed out with a new one(valve labor)?

- dealership wil prolly charge $150-$175 depending on their labor rates. Might find a local shop to do it for less. Goto autozone and ask them to pull the part and to give you a diagram of where it's located and you can decide if you can do it yourself. EGR Exhaust Gas Recirulator typically is located on the intake manifold. Never been under the hood of an 00 Explorer though.

- Q: Hello,I've not found a perfect fit using a solenoid valve for gravity fed irrigation system. Primarily because it requires a constant drain on the battery while the valve is open. Is there a motorized valve to fit the bill? One that momentarily requires electricity to open and close the valve at 12v DC or less to work in gravity fed system?

- I don't know how it specifically wires. There are two strategies for latching devices. One is a solenoid with two coils. Pulse one to open, pulse the other to close. The other strategy is to have one coil. Apply polarity in one direction to open, in the other to close. I suggest googling for latching solenoid valve, and/or checking out the major irrigation (or sprinkler) manufacturers for their offerings.

- Q: Hi, I was wondering if it takes a minute or two for the water to actually turn on after turning the valve? I've turned it as far as I can counter-clockwise but there's still no water. Is there something else that needs to be done to get the water back?

- You should get water almost immediately after turning the valve back on. Is there another valve upstream that was turned off as well?

- Q: Can a dirty or faulty EGR valve cause overheating. My 2001 PT Cruiser is overheating but only on very hot days and when the air conditioning is on. Back flushed and pressure tested the radiator, changed the thermometer, fluid was low but doesn't seem to be loosing fluid since refilled. Check engine light came on and indicated poor air flow through the EGR valve. Is it worth replacing prior to pulling the radiator to check that for the problem with overheating? Mechanic I trust doesn't think the EGR can cause overheating.

- A bad EGR valve can cause a lot of headaches, poor running, bad idle, stalling, etc. One of the few things that it can't cause is overheating. Completely different systems. (side note, make sure that the problem isn't with your EGR sensor, and not the valve). For overheating, here is the diagnostic path: 1: Check for leaks, and that fluid levels are OK. 2: Check for bubbling in the radiator / resivour (while running the engine). Bubbles, especially at high RPM's can indicate a blown head gasket. 3: Check that the thermostat opens. To do this, start a cold car, and place you hand on the upper radiator hose. With gloves on, squeeze it. Wait for a few minutes until the engine warms up. The upper radiator hose will get hot and firm. This indicates that the thermostat is working and the water pump is working. 4: Keep the engine running, and make sure that the cooling fan starts up. Keep your fingers away from the fan. 5: If you can SAFELY do it, reach to the front of the radiator and carefully feel for cold spots on the radiator. If there are cold spots, that means that the radiator is plugged, and needs to be swapped. Good luck.

- Q: How many valves are involved in th etypical 4-stroke cycle? Is it the intake and exhaust valves only? If my car engine has 12 valves, how many cylinders does it have?

- nowadays usually it's four valves per cylinder, though still u may find 2 valves per cylinder. u cann't know how many cylinders u have from knowing the number of valves, it depends on the design.

- Q: freak accident broke the shutoff valve at my toilet, so first thing i did was shut the water off at the main shut off valve inside the house. then fixed the toilet shut off valve then went to turn the water back on at the house valve and it ran for a few seconds and that was it. so i then went to the main valve at the street to make sure it was open. it was open as well as all the others inside the house. still no running water. please help.

- The service valve inside your home may be in dis-repair as well. These valves rarely get used and will have a tendency to stick in the shut position once the valve has been shut. If you have access to the curb stop at the street and can shut it, then you can go back to the service valve, take off the bonnet and see if the gate is stuck in the shut position. A little cleaning, a little Vaseline to lube it up - and you're good to go. Worst case - you'll need to cut it out and replace, preferably with a ball valve.

- Q: I am 31 and just discovered I have severe Mitral Valve Prolapse (Heart probelm). I probably have to have surgery. I have been healthy all my life and I am a little scared. Anyone had surgery for it? What can I expect??

- No okorder /.. If you look at the menu on the left of that page - it should answer most of your questions. Print it out if there are specific things you want to discuss with the cardiologist. Also be sure to click on the minimally invasive surgery Good luck.

Send your message to us

Swing Check Valve Wafer Type Double Disc DN 500 mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 pc

- Supply Capability:

- 100 pc/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords