Steel-work made in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Steel Structure

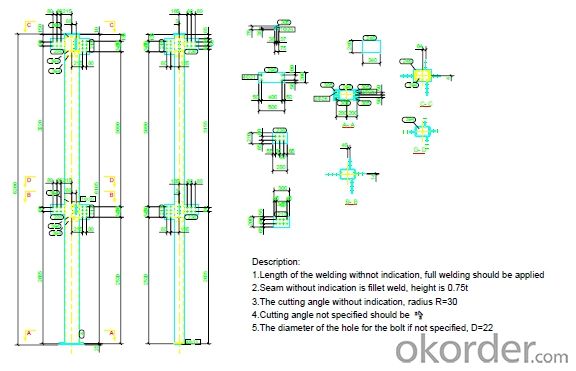

Description:

1.Length of the welding withnot indication,full welding should be applied

2.Seam without indication is fillet weld,height is 0.75t

3.The cutting angle without indication,radius R=30

4.Cutting angle not specified should be 20/20

5.The diameter of the hole for the bolt if not specified, D=22

Project Reference:

Inner Mongolia Shangdu Power Plant is the main source

of west-east power transmission project with total

incestment of 5137 million Yuan. 1,900 tons for the steel

structure of the project with maximum thickness 60mm-

75mm.

- Q: How are steel structures designed for healthcare facilities?

- Steel structures for healthcare facilities are designed with careful consideration for the specific needs and requirements of these buildings. Factors such as load-bearing capacity, flexibility for future expansions, and resistance to seismic forces are taken into account. Additionally, designs prioritize features like fire resistance, infection control, and ease of maintenance to ensure the safety and functionality of healthcare facilities.

- Q: What are the fire protection measures for steel structures?

- Fire protection measures for steel structures include the application of fire-resistant coatings, installation of fire-resistant barriers, use of fire-rated materials, implementation of automatic fire detection and suppression systems, provision of adequate means of escape, and adherence to fire safety regulations and standards.

- Q: How are steel structures connected?

- Steel structures are typically connected through various methods such as welding, bolting, and riveting. Welding is one of the most common methods used to connect steel components. It involves melting the edges of the steel pieces and fusing them together using heat and pressure. Welding provides a strong and permanent connection, making it ideal for structural applications. Bolting is another commonly used method of connecting steel structures. Bolts are inserted through pre-drilled holes in the steel components and tightened with nuts to create a secure connection. Bolting allows for easy disassembly and reassembly, making it suitable for applications where flexibility is required. Riveting is an older method that is still used in certain applications. It involves inserting a hot rivet into pre-drilled holes in the steel components and then hammering it to create a tight connection. While riveting is not as common as welding or bolting, it is still used in situations where aesthetics or historical accuracy are important. In addition to these primary methods, other techniques such as adhesive bonding and mechanical connectors can also be employed to connect steel structures. Adhesive bonding involves using epoxy or other bonding agents to attach steel components together, while mechanical connectors utilize specialized devices to join steel pieces. The choice of connection method depends on factors such as the load requirements, structural design, and the specific application of the steel structure. Each method has its advantages and disadvantages, and engineers must carefully consider these factors to ensure the safety, durability, and functionality of the steel structure.

- Q: What are the different types of steel canopies and shade structures used in buildings?

- Buildings commonly utilize various types of steel canopies and shade structures, which serve the purposes of providing shade, protection, and aesthetic appeal. Presented below are several examples of these different types: 1. Cantilevered Canopies: These canopies are supported on one side and extend outward, offering shade and cover without requiring additional support. They are frequently utilized to form covered walkways or outdoor seating areas. 2. Tensioned Fabric Structures: These structures employ a combination of steel and fabric to construct a lightweight and flexible canopy. The fabric is stretched over the steel frame, resulting in a visually pleasing and functional shade structure. They are commonly found in outdoor spaces such as parking lots, playgrounds, and sports facilities. 3. Barrel Vault Canopies: These canopies possess a curved design resembling a barrel. They are frequently used to cover large areas like outdoor stages, amphitheaters, or entrance areas. The curved shape of the canopy provides an elegant and captivating architectural feature. 4. Gable Canopies: These canopies possess a triangular shape with two sloping sides that meet at a ridge in the middle. They are commonly employed to cover entrances, walkways, or outdoor seating areas. The gable design offers a traditional and visually pleasing appearance. 5. Trellis Structures: These structures consist of a steel frame with open spaces or lattice-like patterns. They are often utilized to create shaded areas in gardens, patios, or outdoor dining spaces. The open design allows sunlight to filter through while providing partial shade. 6. Louvered Canopies: These canopies feature adjustable slats or louvers that can be angled to control the amount of sunlight and shade. They are commonly found in outdoor dining areas, patios, or rooftop gardens. The adjustable louvers offer flexibility in providing shade or allowing sunlight to pass through. 7. Monoslope Canopies: Also referred to as single-slope canopies, these structures possess a single slope or pitch. They are frequently used to cover walkways, parking areas, or loading docks. The monoslope design allows for efficient rainwater runoff and provides a modern and functional appearance. These are merely a few examples of the diverse range of steel canopies and shade structures employed in buildings. The choice of canopy design depends on various factors such as the purpose, location, and architectural style of the building.

- Q: What is the role of steel connections in a steel structure?

- The role of steel connections in a steel structure is to join different steel members together, ensuring structural stability, load transfer, and overall integrity of the structure. These connections are crucial in distributing loads and forces throughout the structure, allowing it to withstand various external forces such as gravity, wind, seismic activity, and other environmental factors. Additionally, steel connections facilitate flexibility and adaptability in design, allowing for efficient construction and potential future modifications or expansions.

- Q: What does LL represent in steel structures?

- Generally, coupling beams have small span, large section and large stiffness of wall connected with coupling beams. Generally, the internal forces of the coupling beams are often large under the influence of wind and earthquake loads. In the calculation of internal force, the stiffness of the coupling beam is usually reduced, but the displacement calculation is usually not reduced.

- Q: What is the performance and function of steel structure engineering?

- Resistant to 70 meters per second hurricane, steel structure wind resistance: steel structure construction light weight, high strength, overall rigidity, deformation ability. The weight of the building is only 1/5 of that of the brick concrete structure. Maintain the life and property effectively.

- Q: What are the considerations for the design of steel structures in areas with expansive soils?

- To ensure the stability and longevity of steel structures in areas with expansive soils, several factors must be taken into account. Firstly, a thorough geotechnical investigation should be conducted to assess the characteristics of the expansive soils. This includes determining the soil type, moisture content, plasticity, and swell potential. This information is essential for designing appropriate foundations and accounting for potential soil movements. The foundation system needs to be designed in such a way as to accommodate the expansive soil movements. This may involve using deep foundations, such as piles or caissons, to reach stable soil layers. Alternatively, shallow foundations with additional measures, such as reinforced concrete beams, can be employed to mitigate soil movement. The foundation design should consider both the anticipated soil movements and the structural loads. The steel structure's framing system should be designed to be flexible enough to accommodate the potential movements of the foundation. This can be achieved by using flexible connections between columns and beams, which allow for some degree of movement without causing structural damage. Additionally, the framing system should be designed to distribute loads efficiently and minimize localized stresses caused by uneven soil movements. Expansion joints should be incorporated into the steel structure to accommodate potential differential movements between different parts of the building caused by expansive soils. These joints allow for controlled movement without transferring excessive stresses to the structure, thereby ensuring its integrity over time. Effective drainage systems should be implemented to manage the moisture content of the soil. This includes proper grading, surface runoff control, and foundation drainage systems, which can help prevent excessive water accumulation and minimize soil movements. Moisture control measures, such as moisture barriers or ventilation systems, may also be necessary within the structure to mitigate the effects of expansive soils. Regular monitoring of the steel structure and its foundation should be carried out to detect any signs of movement or distress. This can be achieved by using instruments to measure soil moisture, vertical movement, or structural displacements. If movement or damage is detected, prompt maintenance and remedial actions should be undertaken to ensure the long-term stability of the structure. In conclusion, designing steel structures in areas with expansive soils requires a comprehensive understanding of the soil characteristics and potential movements. By considering factors such as foundation design, structural framing, expansion joints, drainage, and monitoring, engineers can design steel structures that can withstand the challenges posed by expansive soils and ensure their safety and durability.

- Q: Can steel structures be designed to be resistant to terrorist attacks?

- Yes, steel structures can be designed to be resistant to terrorist attacks. Through careful planning and implementation of security measures, such as blast-resistant design, reinforced structural elements, and enhanced perimeter protection, steel structures can be made more resilient against terrorist threats. Additionally, advanced technologies like surveillance systems and access control measures can further enhance the security of steel structures, making them less vulnerable to potential attacks.

- Q: What does steel column support between columns mean?

- A connecting bar between two adjacent columns to ensure the overall stability of the building structure, to improve lateral stiffness and to transmit longitudinal horizontal forces

Send your message to us

Steel-work made in China

- Loading Port:

- China Main Port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- -

- Supply Capability:

- -

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords