Steel Structure Warehouse/Workshop GB Standard Material

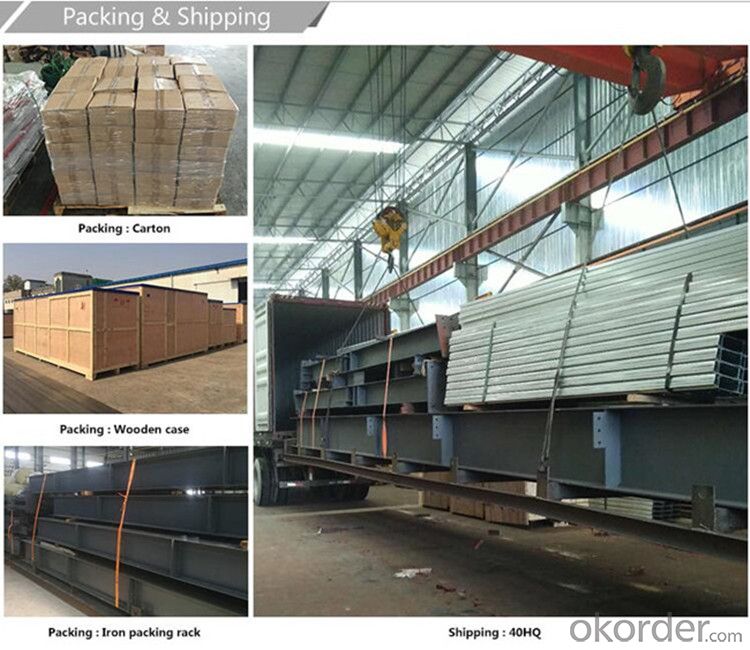

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

Steel Structure Warehouse/Workshop

1. These products are customized products;

2. The following information is required to provide detailed quotation:

A. Project location:

B. Size: Length*width*height _____mm*_____mm*_____mm

C. Wind load (max. Wind speed) _____kn/m2, _____km/h, _____m/s

D. Snow load (max. Snow thickness)_____kn/m2, _____mm

E. Anti-earthquake grade_____

F. Brick wall needed or not. If yes, 1.2m high or 1.5m high?

G. Thermal insulation requirement. If yes, EPS/fiberglass wool/rock wool/PU sandwich panels will be suggested; If not, the metal steel sheets will be OK. The cost of the latter will be much lower than the former.

H. Door quantity & size _____units, _____(width)mm*_____(height)mm

I. Window quantity & size _____units, _____(width)mm*_____(height)mm

J. Crane needed or not

Characteristics

1. Enviromental friendly

2. Lower cost and maintenance

3. Long using time up to 50 years

4. Stable and earthquake resistance up to 9 grade

5. Fast construction, time saving and labor saving

6. Good appearance

Use

The steel workshop warehouse building is widely used for workshop plant, warehouse, office building,steel shed, aircraft hangar etc.

Technical Parameters

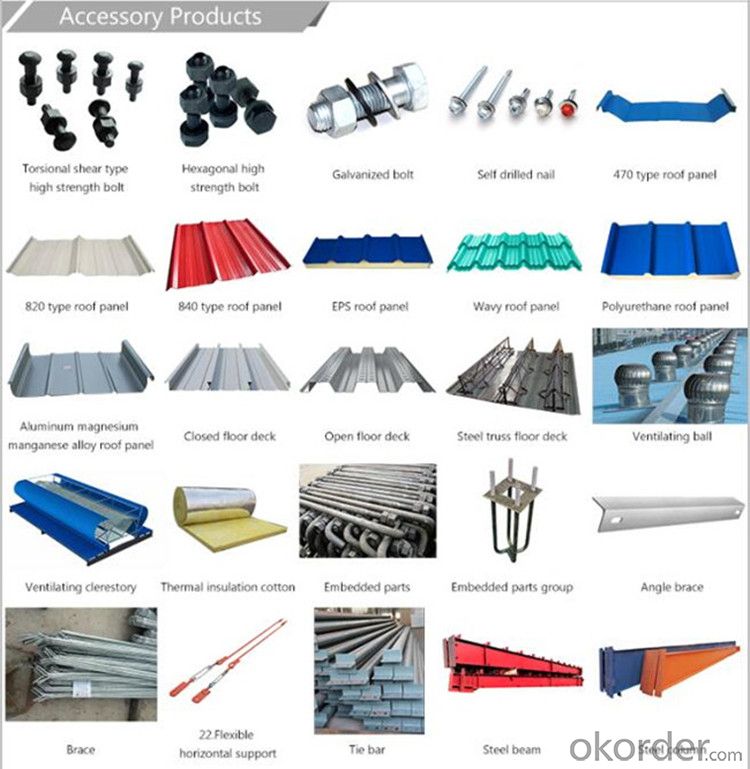

Items | Specification | |

Main Steel Frame | Column | Q235B, Q345B Welded H Section Steel |

Beam | Q235B, Q345B Welded H Section Steel | |

Secondary Frame | Purlin | Q235B C and Z purlin |

Knee brace | Q235B Angle Steel | |

Tie Rod | Q235B Circular Steel Pipe | |

Brace | Q235B Round Bar | |

Vertical and Horizontal Support | Q235B Angle Steel, Round Bar or Steel Pipe | |

Maintenance system | Roof Panel | EPS Sandwich Panel / Glass Fiber Sandwich Panel /Rock Wool Sandwich Panel / Pu Sandwich Panel /Steel Sheet |

Wall Panel | Sandwich Panel / Corrugated Steel Sheet | |

Accessories | Window | Aluminium Alloy Window / PVC Window / Sandwich Panel Window |

Door | Sliding Sandwich Panel Door / Rolling Metal Door / Personal Door | |

Rainspout | PVC | |

Live load on Roof | In 120kg/Sq.m (Color steel panel surrounded) | |

Wind Resistance Grade | 12 Grades | |

Earthquake-resistance | 8 Grades | |

Structure Usage | Up to 50 years | |

Finishing Options | Vast array of colors and textures available | |

Paint Options | Zinc rich epoxy painting, one primary painting, two finish painting (gray paint, red paint, white paint, epoxy zinc etc.) Or Galvanized. | |

- Q: What are the design considerations for steel canopies and covered parking?

- When it comes to designing steel canopies and covered parking structures, there are several crucial factors to consider. These factors encompass: 1. Ensuring structural strength: It is imperative to design steel canopies and covered parking structures that can withstand a range of weather conditions, including wind, snow, and heavy rain. The structural design should be capable of supporting not only the weight of the canopy itself but also any additional loads, such as solar panels or lighting fixtures. The utmost priority is to guarantee a stable and durable structure, preventing any potential collapses or damages. 2. Focusing on aesthetics: The design of steel canopies and covered parking structures should be visually appealing and harmonize with the surrounding environment or architectural style. This can be achieved by carefully selecting suitable materials, colors, and finishes that seamlessly blend with the overall aesthetic of the area. The design should also take into account any necessary signage or branding elements that need to be incorporated. 3. Meeting functional requirements: The design should address specific functional needs, such as determining the required number of parking spaces, the width of the parking bays, and the necessary height clearance for vehicles. The layout should prioritize efficiency, providing ease of access and maneuverability for both drivers and pedestrians. Additionally, the design should consider the installation of proper lighting, ventilation, and drainage systems to enhance safety and improve the user experience. 4. Considering environmental factors: It is vital to incorporate sustainable design principles into the creation of steel canopies and covered parking structures. This includes considering the use of eco-friendly materials, such as recycled steel, and integrating energy-efficient features like solar panels or rainwater harvesting systems. The design should also account for potential future upgrades or expansions to accommodate changing needs and technologies. 5. Prioritizing safety and security: Safety should take precedence when designing steel canopies and covered parking structures. This entails ensuring adequate lighting and visibility, incorporating appropriate signage and wayfinding, and integrating security measures like surveillance cameras or access control systems. Additionally, the design should consider fire safety measures, such as utilizing fire-resistant materials or installing sprinkler systems. In conclusion, designing steel canopies and covered parking structures requires a comprehensive approach that balances structural integrity, aesthetics, functionality, environmental sustainability, and safety. By addressing these considerations, designers can create visually pleasing and long-lasting structures that cater to the needs of users and the surrounding environment.

- Q: How are steel structures used in sports training facilities?

- Steel structures are commonly used in sports training facilities due to their durability, strength, and versatility. They provide the necessary support for large open spaces, such as indoor stadiums, training halls, and gyms. Steel beams and columns are used to create the framework for these structures, allowing for the construction of high ceilings and wide spans without the need for excessive columns or walls. This enables athletes to train in spacious environments, accommodating various sports activities and equipment. Additionally, steel structures can be easily customized and modified to meet specific training requirements, making them ideal for sports facilities that need to adapt to changing needs over time.

- Q: How are steel structures designed for blast-resistant windows?

- Steel structures engineered for blast-resistant windows are meticulously designed to endure the forces generated by an explosion, prioritizing the safety and integrity of the building and its occupants in such an event. The design process commences with an analysis of the potential blast load that the building may encounter. This analysis encompasses various factors, including the size and type of explosive device, the proximity of the blast source, and the building's distance from neighboring structures. By comprehending the blast load, engineers can ascertain the necessary strength and resistance requirements for the steel structure. Once the blast load is determined, the steel structure is devised to absorb and distribute the energy produced by the explosion. This is achieved through a combination of factors, such as the thickness and strength of the steel elements, the type of connections employed, and the overall structural configuration. Reinforced steel columns, beams, and frames are frequently utilized to augment the structure's ability to withstand blast forces. Apart from the strength of the steel structure, blast-resistant windows assume a pivotal role in safeguarding the building. These windows are specifically designed to withstand the pressure and flying debris resulting from an explosion. Typically composed of laminated or tempered glass with a robust interlayer, these windows prevent shattering upon impact. Furthermore, the window frames are reinforced to enhance support and resistance against blast forces. To ensure the efficacy of the design, engineers may employ computer simulations and structural analysis software to simulate and test the steel structure's response to blast loads. These simulations aid in identifying potential vulnerabilities and guiding the design process to enhance the structure's blast resistance. In conclusion, the design of steel structures for blast-resistant windows necessitates a comprehensive understanding of blast dynamics, meticulous selection of materials and construction techniques, and rigorous testing and analysis. By incorporating these considerations, buildings can be better equipped to withstand the devastating forces of an explosion, thereby enhancing the safety of occupants and minimizing structural damage.

- Q: What are the considerations for designing steel structures in areas with high wind loads?

- There are several key factors to consider when designing steel structures in areas with high wind loads. These considerations are crucial for ensuring the safety and durability of the infrastructure: 1. Accurate Wind Load Calculation: The initial step involves accurately determining the wind loads that the structure will face. This requires a careful assessment of local wind patterns, directionality, and intensity. Wind load calculations can be conducted using established codes and standards, such as ASCE 7 or Eurocode. 2. Structural Stability: The design of steel structures must ensure that they can withstand the wind loads without experiencing excessive deflection or failure. Achieving structural stability involves considering factors like the structure's shape and profile, bracing systems, and connections between structural members. 3. Appropriate Material Selection: Selecting the right grade of steel is crucial for withstanding high wind loads. High-strength steel with good ductility and toughness is often preferred since it provides better structural integrity and resistance against wind-induced forces. 4. Optimized Aerodynamic Design: The shape and profile of the structure should be optimized to minimize wind resistance and reduce the possibility of vortex shedding, which can lead to dynamic instabilities. Incorporating aerodynamic features, such as streamlined shapes or tapered sections, can help mitigate wind-induced vibrations. 5. Carefully Designed Connections: The connections between structural members need to be meticulously designed to ensure their integrity under high wind loads. Employing proper connection detailing, such as using high-strength bolts or welds, can enhance the overall strength and stability of the structure. 6. Well-Designed Foundation System: The foundation system must be designed to effectively transfer the wind loads from the structure into the ground. Adequate soil investigation and foundation design are critical to ensure that the foundation can resist the lateral forces generated by the wind. 7. Additional Wind Breakers or Barriers: In some cases, it may be necessary to include additional wind breakers or barriers to reduce the wind load on the structure. These features can consist of wind fences, wind screens, or adjacent buildings that help redirect or dissipate the wind forces. 8. Regular Maintenance and Inspection: Regular inspections and maintenance of the steel structure are essential to ensure its long-term performance in high wind load areas. This includes checking for corrosion, damage, or any signs of structural degradation that could compromise its integrity. By considering these factors, engineers can design steel structures that can safely withstand high wind loads, ensuring the safety and longevity of the infrastructure in areas prone to strong winds.

- Q: What is the purpose of steel beams in structures?

- Steel beams serve the purpose of providing structural support and stability in various structures. With their strength and durability, they are capable of withstanding heavy loads and resisting bending or buckling when subjected to pressure. They find common usage in the construction of buildings, bridges, and other large structures to evenly distribute weight and prevent collapse. Moreover, steel beams enable the creation of open and flexible floor plans as they can span long distances without the necessity of additional support columns. Furthermore, steel beams possess fire resistance, rendering them suitable for structures that require enhanced safety measures. Ultimately, the aim of steel beams is to guarantee the integrity and longevity of a structure by establishing a solid and dependable framework.

- Q: How are steel structures designed for thermal comfort?

- Various strategies can be employed to achieve thermal comfort in steel structures, aiming to regulate internal temperature and enhance occupants' comfort. Insulation is a key consideration, as effective insulation materials incorporated into the walls, roofs, and floors of steel structures can minimize heat transfer, reducing heat gain or loss from the external environment. This insulation helps maintain a stable internal temperature, minimizing the need for excessive heating or cooling. Efficient HVAC systems are another aspect of thermal comfort design for steel structures. These systems can be tailored to provide adequate heating or cooling based on the specific requirements of the building and its occupants. By ensuring proper airflow and temperature control, occupants can enjoy a comfortable indoor environment throughout the year. The orientation and placement of windows and shading devices are also important design considerations. By strategically positioning windows to maximize natural light while minimizing direct sunlight exposure, passive solar heating can be utilized to provide additional warmth during colder months. Shading devices like blinds or overhangs can also help prevent solar heat gain during warmer months, preventing overheating. The selection of appropriate building materials plays a crucial role in steel structure design for thermal comfort. For example, using high-performance glazing with low solar heat gain coefficients can help reduce unwanted heat transfer. Additionally, incorporating thermal mass materials like concrete or stone in the building envelope can regulate temperature fluctuations by absorbing and releasing heat gradually. Lastly, advanced technologies such as smart controls and energy management systems can optimize energy consumption and enhance thermal comfort. These systems can monitor and adjust temperature, humidity, and ventilation levels based on occupancy patterns and weather conditions, ensuring a comfortable and energy-efficient indoor environment. In conclusion, achieving thermal comfort in steel structures involves implementing insulation, efficient HVAC systems, strategic window placement, shading devices, appropriate building materials, and advanced technologies. Architects and engineers can create steel structures that promote a comfortable and sustainable living or working environment by considering these factors.

- Q: How are steel structures used in data centers and server farms?

- Steel structures are an integral component of data centers and server farms due to their strength, durability, and versatility. These structures provide a stable framework that supports the heavy equipment and infrastructure required in these facilities. One of the primary uses of steel structures in data centers and server farms is to house server racks and cabinets. These structures provide the necessary support and security for the servers, ensuring that they are safely stored and easily accessible for maintenance and upgrades. The steel racks also offer efficient cable management solutions, reducing the risk of tangled wires and improving airflow for optimal cooling. Moreover, steel structures are essential for creating raised floors in these facilities. Raised floors provide a space underneath for cables, power lines, and cooling systems, enabling organized and efficient distribution of these elements throughout the data center. The strength of steel ensures that the raised floors can bear the weight of heavy equipment, ensuring a safe working environment for technicians. Additionally, steel structures are used in the construction of data center buildings themselves. Steel frames provide the necessary strength and stability to support the weight of the infrastructure and equipment housed within the facility. They also offer flexibility in terms of design and layout, allowing for easy expansion and reconfiguration as the needs of the data center evolve over time. Furthermore, steel structures contribute to the overall safety and security of data centers and server farms. Steel is known for its fire-resistant properties, which is crucial in protecting the valuable data and equipment stored within these facilities. Additionally, steel structures can be designed to withstand natural disasters such as earthquakes and hurricanes, ensuring the continuity of operations even under adverse conditions. In conclusion, steel structures play a vital role in data centers and server farms by providing the necessary support, security, and flexibility required for these facilities. From server racks to raised floors and entire building constructions, steel is an essential component that ensures the efficient and safe operation of data centers and server farms.

- Q: What are the guidelines for the maintenance and inspection of steel structures?

- The guidelines for the maintenance and inspection of steel structures typically include regular visual inspections to identify any signs of corrosion, cracking, or other structural issues. It is important to follow manufacturer recommendations for cleaning and maintenance, including regular washing and removal of any debris that can contribute to corrosion. Additionally, periodic structural inspections by certified professionals are crucial to ensure the integrity and safety of the steel structure. Regular maintenance and inspections help to identify and address any potential issues early on, preventing costly repairs or structural failures.

- Q: How do steel structures provide resistance against fire-induced collapse?

- Steel structures provide resistance against fire-induced collapse through several mechanisms. Firstly, steel has a high melting point, typically around 1370°C (2500°F), which means it can withstand higher temperatures compared to other materials like wood or concrete. This allows steel structures to maintain their structural integrity for a longer duration during a fire. Secondly, steel has a low thermal conductivity, meaning it does not readily transfer heat. This characteristic slows down the transfer of heat from the fire to the steel structure, preventing rapid temperature rise and maintaining its strength. Additionally, steel members in a structure are often protected by fire-resistant materials like intumescent coatings or fireproof insulation. These coatings or insulation act as a barrier, delaying the heating of the steel and providing extra time for evacuation or firefighting efforts. Furthermore, steel structures are designed using fire-resistant techniques such as compartmentation, fire-resistant walls, and fire barriers. These measures help contain the fire, preventing its spread and reducing the overall impact on the structure. Overall, the combination of steel's high melting point, low thermal conductivity, fire-resistant coatings, and design techniques make steel structures more resistant to fire-induced collapse compared to other materials.

- Q: What is called a steel rivet?

- It's going to be an antique. Aluminum or steel rivets are used for locking structures when they are used for retaining structures, not for structural purposes. As for the thin steel plate, the steel structure is not good, and at the very least, the structural professional pays little attention to rivet pulling.

Send your message to us

Steel Structure Warehouse/Workshop GB Standard Material

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 100 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords