Steel Frame Formwork High Quality and Flexible GK120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

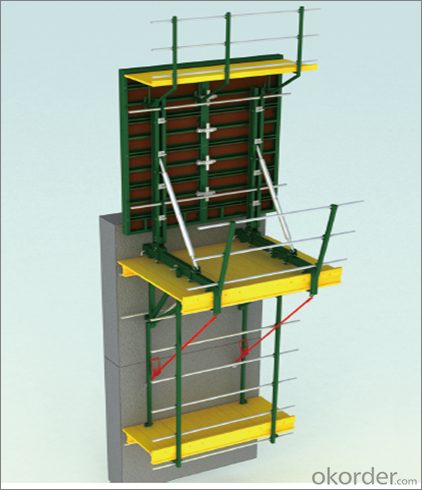

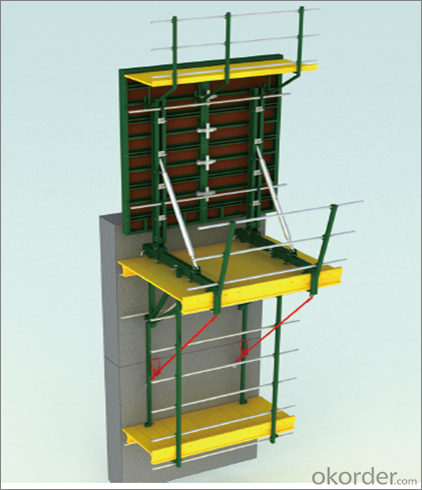

1. Structure of Steel Frame Formwork GK120

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

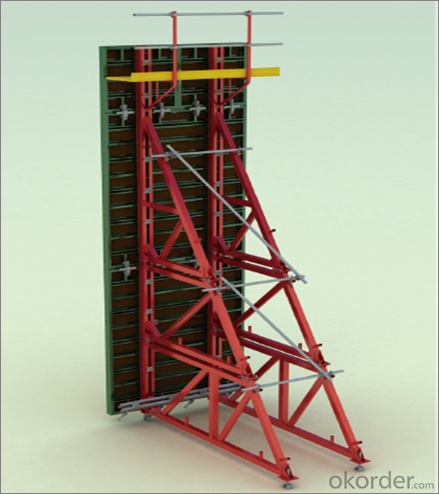

2. Main Features of Steel Frame Formwork GK120

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

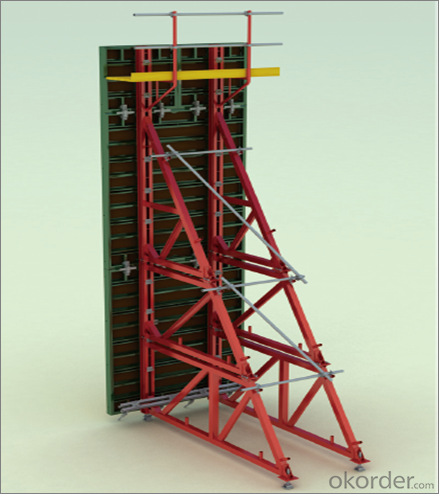

3. Steel Frame Formwork GK120 Images

4. Steel Frame Formwork GK120 Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork GK120

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork GK120, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork GK120, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: PKPM how to add lateral restraint steel frame

- Hello,PKPM is not directly added to the argument, the landlord did not express clear

- Q: What are the different types of formwork shoes used in steel frame formwork systems?

- Steel frame formwork systems utilize various types of formwork shoes for different purposes. Some commonly used types include adjustable screw jacks, flat steel shoes, U-head shoes, base plates, and castor shoes. Adjustable screw jacks, typically made of steel, allow for easy height adjustment and leveling of the formwork system. They provide support and stability. Flat steel shoes, consisting of flat steel plates, serve as a stable base for the formwork system. They are placed under the vertical members to evenly distribute the load and prevent sinking or tilting. U-head shoes, designed in a U shape, support horizontal beams or joists in the formwork system. They work alongside adjustable screw jacks to enhance support and stability. Base plates, made of steel, establish a solid foundation for the formwork system. They are placed directly on the ground or a concrete slab to support the vertical members. Castor shoes, equipped with castor wheels, enable mobility in the formwork system. They allow for easy movement and can be locked to ensure stability during construction. Choosing the appropriate formwork shoes depends on project-specific requirements, such as load-bearing capacity, height adjustment needs, and mobility requirements. It is crucial to select the right type to ensure the stability and safety of the steel frame formwork system.

- Q: Are there any environmental concerns associated with steel frame formwork?

- There are indeed some environmental concerns linked to steel frame formwork. Firstly, the production of steel requires a significant amount of energy and results in the emission of greenhouse gases, which contribute to climate change. The extraction and processing of raw materials for steel production also have detrimental effects on the environment, such as deforestation and the destruction of habitats. Moreover, steel frame formwork is often used only once for a specific construction project and then discarded, leading to a significant amount of waste generation and contributing to pollution in landfills. On the other hand, reusable formwork systems made from sustainable materials like bamboo or recycled plastic can help reduce waste and minimize environmental impacts. Furthermore, the transportation of steel formwork to construction sites requires fuel consumption and results in transportation emissions, which can further contribute to air pollution and carbon emissions. However, it is worth noting that steel formwork also has its advantages. It is durable, strong, and easy to assemble and disassemble, making it popular in the construction industry. Additionally, steel can be recycled, which helps reduce the environmental impact of its disposal. To address the environmental concerns associated with steel frame formwork, it is crucial to focus on improving the overall sustainability of construction practices. This can involve using more eco-friendly alternatives, implementing efficient waste management strategies, promoting recycling, and adopting sustainable transportation methods. Additionally, incorporating renewable energy sources into steel production can help reduce its carbon footprint.

- Q: How does steel frame formwork help in reducing formwork assembly time?

- Steel frame formwork helps in reducing formwork assembly time because it is a prefabricated system that can be easily assembled and disassembled. The steel frames provide stability and support, allowing for faster and more efficient installation of formwork panels. Additionally, the use of steel frame formwork eliminates the need for traditional timber formwork, which requires time-consuming cutting and shaping. Overall, steel frame formwork offers a quicker and more streamlined process for constructing concrete structures.

- Q: How does steel frame formwork handle concrete curing in cold conditions?

- Steel frame formwork handles concrete curing in cold conditions by providing a strong and stable structure that helps to retain and distribute heat during the curing process. The steel frame acts as a thermal conductor, allowing any heat generated by the concrete's exothermic reaction to be efficiently transferred and distributed throughout the structure. This helps to maintain a consistent and sufficient temperature for the concrete to cure properly, even in cold weather conditions. Additionally, the steel frame provides a protective enclosure that helps to prevent the concrete from freezing, ensuring that the curing process is not interrupted or compromised by the cold temperatures.

- Q: What are the different components of steel frame formwork?

- The different components of steel frame formwork typically include: 1. Panels: Steel frame formwork panels are the main component of the system. These panels are usually made of steel or aluminum and are designed to be lightweight yet sturdy. They come in various sizes and shapes, such as rectangular or square, and are available in different thicknesses based on the required strength and load-bearing capacity. 2. Connecting pins: Connecting pins are used to connect the panels together, ensuring a tight and secure formwork system. These pins are usually made of steel and are inserted through pre-drilled holes in the panels, providing stability and preventing any movement or displacement during concrete pouring. 3. Wedges: Wedges are used in conjunction with the connecting pins to further secure the formwork system. They are typically made of steel or plastic and are inserted between the panels and pins, creating a tight fit and preventing any gaps or spaces that could lead to leakage or uneven concrete placement. 4. Props: Props are vertical support devices used to provide additional strength and stability to the formwork system. They are usually made of steel and are adjustable in height, allowing for flexibility in formwork installation. Props are essential in supporting the weight of the concrete and the formwork itself, ensuring a safe and reliable construction process. 5. Braces: Braces are horizontal or diagonal supports that are used to reinforce the formwork system and prevent any buckling or bending of the panels. They are typically made of steel and are installed at regular intervals to provide additional stability and rigidity to the formwork structure. 6. Formwork accessories: In addition to the main components, steel frame formwork may also include various accessories such as clamps, ties, and brackets. These accessories are used to secure the formwork system to the existing structure, align the panels accurately, and provide additional reinforcement where needed. Overall, the different components of steel frame formwork work together to create a robust and reliable system for concrete construction. The combination of panels, connecting pins, wedges, props, braces, and accessories ensures a strong and stable formwork structure that can withstand the pressures and forces exerted during the concrete pouring process.

- Q: Can steel frame formwork be used for curved structures?

- Yes, steel frame formwork can be used for curved structures. Steel frame formwork is versatile and can be easily adjusted or modified to create curved or complex shapes. This is achieved by using flexible plywood or metal sheets that can be bent or shaped to fit the desired curve. Additionally, steel frame formwork provides excellent strength and stability, making it suitable for constructing both straight and curved structures.

- Q: How does steel frame formwork handle different types of formwork curing techniques?

- Steel frame formwork is highly versatile and can effectively handle different types of formwork curing techniques. The steel frame provides stability and strength, allowing for various curing methods such as air curing, water curing, and chemical curing to be easily implemented. Additionally, the adjustable nature of steel formwork allows for precise control over the curing process, ensuring the desired level of strength and durability in the final concrete structure.

- Q: How does steel frame formwork accommodate for different concrete placement methods?

- The adaptability and versatility of steel frame formwork make it a suitable system for accommodating different concrete placement methods. One way it achieves this is through adjustable panel sizes, allowing for customization to match the desired shape and dimensions of the concrete structure. This flexibility ensures efficient and accurate concrete placement, regardless of whether traditional pouring, pumping, or layer pouring is required. Moreover, steel frame formwork can incorporate various accessories and additional components to support different concrete placement methods. These may include adjustable braces, tie rods, and connectors, among others. By withstanding the pressure and weight of the concrete during pouring, these components ensure the stability and integrity of the structure. Steel frame formwork also facilitates easy access for reinforcement installation. Its design allows for the placement of reinforcing bars, mesh, or other reinforcement materials, ensuring the structural strength and durability of the cured concrete. Furthermore, the ease with which steel frame formwork can be dismantled and reassembled makes it suitable for repetitive use in projects with multiple concrete placements. This feature contributes to efficient and cost-effective construction, as the formwork can be quickly adjusted and reused for subsequent pours. In conclusion, steel frame formwork's adjustable panel sizes, incorporation of accessories, provision for reinforcement installation, and ease of dismantling and reassembly all contribute to its adaptability and versatility in accommodating various concrete placement techniques.

- Q: How does steel frame formwork contribute to the overall efficiency of concrete placement and compaction?

- Steel frame formwork contributes to the overall efficiency of concrete placement and compaction in several ways. Firstly, steel frame formwork provides a stable and rigid structure that helps to maintain the shape and dimensions of the concrete elements being formed. This ensures accurate and precise placement of the concrete, resulting in a more efficient construction process. The steel frames are designed to withstand the pressure exerted by the wet concrete, preventing any deformation and maintaining the desired shape of the structure. Secondly, steel frame formwork allows for easy and quick assembly and disassembly. The frames are usually prefabricated and can be easily transported and assembled on-site. This saves time and labor, making the construction process more efficient. Additionally, steel frame formwork can be reused multiple times, further reducing the overall time and cost of the project. Furthermore, steel frame formwork provides a smooth and even surface for concrete compaction. The rigid structure of the steel frames prevents any bulging or sagging of the formwork, ensuring that the concrete is evenly distributed and compacted. This results in a higher quality finish and reduces the need for additional compaction efforts, saving time and resources. Lastly, steel frame formwork allows for easy access to the concrete during the placement and compaction process. The frames can be designed with openings and access points, providing convenient access for workers and equipment. This facilitates efficient pouring and compaction, as workers can easily reach all areas of the formwork, ensuring proper consolidation and eliminating the risk of voids or weak spots in the concrete. In conclusion, steel frame formwork significantly contributes to the overall efficiency of concrete placement and compaction. It provides stability, accuracy, reusability, and easy access, resulting in a more streamlined construction process and a higher quality finished product.

Send your message to us

Steel Frame Formwork High Quality and Flexible GK120

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches