Steel Frame Formwork with Thickness of 18mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

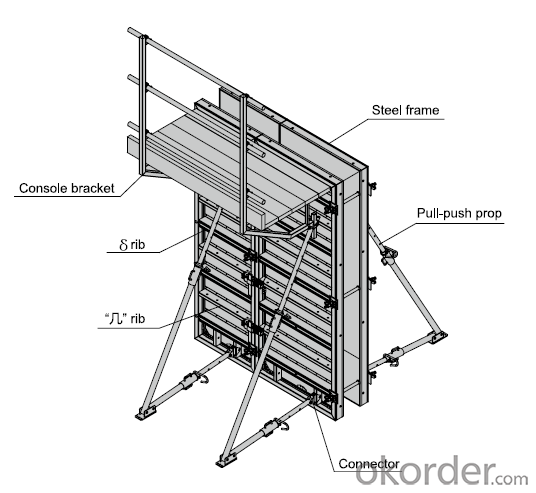

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

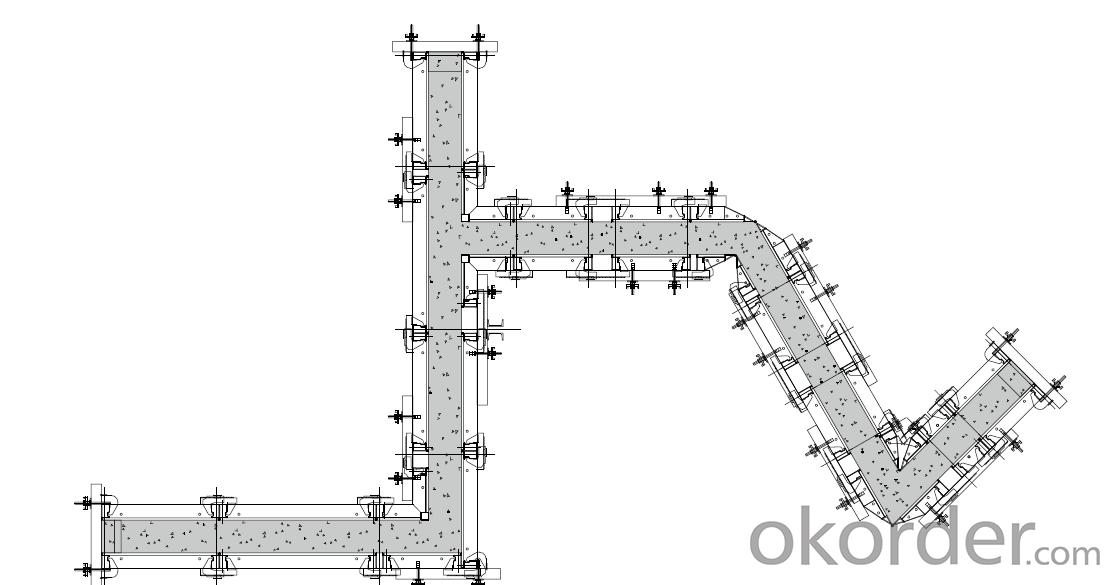

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork GK120 cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: How long does it take to assemble steel frame formwork?

- The assembly time for steel frame formwork can vary depending on several factors, including the size and complexity of the structure, the workers' experience and skill level, and the availability of equipment. On average, completing the assembly process can take anywhere from a few days to a couple of weeks. For smaller or simpler structures, setting up and securing the steel frames may only take a few days. During this stage, the frames are positioned according to the design specifications, securely connected, and checked for levelness and alignment. Any necessary adjustments or modifications may also be made at this time. However, for larger or more complex structures, the assembly process can take longer. This is due to a higher number of steel frames to install and align, additional bracing and support systems to incorporate, and more intricate connections to make. In such cases, it may take several weeks to complete the assembly process, especially if there are any unforeseen challenges or delays. It is important to note that the assembly time mentioned here specifically refers to the steel frame formwork itself and does not include tasks such as pouring and curing the concrete, which will add extra time to the overall construction timeline. To determine the precise assembly time for steel frame formwork in a particular project, it is advisable to consult experienced construction professionals who can assess the project requirements and provide a more accurate estimate.

- Q: Can steel frame formwork be used for complex architectural designs?

- Yes, steel frame formwork can be used for complex architectural designs. Steel frame formwork is a versatile and adaptable system that can be customized to fit various shapes and sizes. It provides the necessary strength and stability to support and mold concrete into complex architectural designs. The steel frames can be easily adjusted and interconnected to create intricate forms, curves, and angles, allowing for the realization of unique and challenging architectural structures. Additionally, steel frame formwork is durable, reusable, and can withstand the pressure and weight of the concrete, making it a suitable choice for complex architectural designs that require precision and stability.

- Q: What are the different types of ties used to secure the formwork to the concrete structure?

- There are several types of ties commonly used to secure formwork to a concrete structure. Some of the most popular types include snap ties, flat ties, wedge bolts, form aligners, and loop ties. Each type of tie serves a specific purpose and offers different advantages in terms of ease of use, strength, and reusability. Ultimately, the choice of tie depends on the specific requirements of the construction project and the preferences of the contractor.

- Q: ANSYS steel frame structure modeling, commonly used in size, density, Poisson's ratio is much better? Help。

- Such as the large cross-section of channel steel, I-beam, density 7.85x10^3/m^3

- Q: What are the requirements for the installation and the characteristics of the chimney sliding formwork

- Main principles of formwork engineering design1 practicality: the template to ensure that the components of the shape and size of the correct position, and the structure is simple, easy to open, smooth surface, tight joints, etc..

- Q: Are there any maintenance requirements for steel frame formwork?

- Yes, there are maintenance requirements for steel frame formwork. Regular inspection and cleaning of the formwork is necessary to remove any debris or concrete residue that may affect its performance. Additionally, any rust or corrosion should be treated and repaired promptly to ensure the longevity and structural integrity of the steel frame formwork.

- Q: How are steel frame formwork panels connected together?

- The connection of steel frame formwork panels typically involves a system of pins, clips, and wedge bolts. These components are specifically designed to interlock and securely hold the panels in place, ensuring a stable and robust formwork structure. To begin with, the steel frame formwork panels feature holes or slots along their edges at various intervals. These openings serve as anchor points for the connecting components. Pins are inserted into these holes to align and secure the panels together. These pins offer flexibility, as they can be easily inserted and removed, allowing for adjustments to the formwork configuration as required. Once the panels are aligned with the assistance of pins, clips are employed to further reinforce the connection. Made of steel, these clips tightly fit onto the edges of the formwork panels. Their purpose is to maintain panel alignment and prevent any movement or shifting during the concrete pouring process. In addition to pins and clips, wedge bolts are utilized to strengthen the connection between the steel frame formwork panels. These bolts are inserted through holes in the clips and tightened using a wrench or hammer. As the wedge bolt is tightened, it generates a powerful clamping force that securely holds the panels together. The combination of pins, clips, and wedge bolts guarantees a secure and stable connection between the steel frame formwork panels. This connection system enables the easy assembly and disassembly of the formwork, making it efficient and time-saving for construction projects.

- Q: Airtight door and all glass steel frame door which cost is high

- It should be airtight door, somehow there are some technical content

- Q: How to fix the glass brick on the steel frame

- Generally can use glass glue and steel frame fixed, pay attention not to use the corrosion of the glue, general neutral can.

- Q: What are the different types of access systems used with steel frame formwork?

- There are several different types of access systems that can be used with steel frame formwork, depending on the specific requirements of the construction project. One commonly used access system is the ladder system. This involves attaching ladders to the steel frame formwork, which allows workers to easily climb up and down the formwork structure. Ladder systems are typically used for smaller structures or when access is only needed at certain points along the formwork. Another type of access system is the stair tower system. This involves constructing a separate tower structure alongside the steel frame formwork, which contains stairs or a ladder system. Stair tower systems are more commonly used for larger structures or when access is required at multiple levels of the formwork. In some cases, a platform system may be used as an access system with steel frame formwork. This involves constructing a platform structure that is attached to the steel frame formwork, providing a stable and secure platform for workers to access the formwork. Platform systems are often used when there is a need for extended access or when multiple workers need to access the formwork at the same time. Additionally, a crane or hoist system may be used as an access system with steel frame formwork. This involves using a crane or hoist to lift workers and materials up to the formwork structure. Crane or hoist systems are typically used when there is limited space for traditional access systems or when heavy materials need to be lifted onto the formwork. Overall, the choice of access system for steel frame formwork will depend on factors such as the size and complexity of the structure, the level of access required, and the specific needs of the construction project.

Send your message to us

Steel Frame Formwork with Thickness of 18mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords