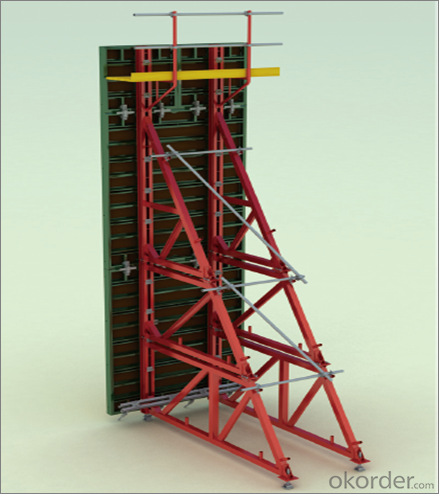

SF120 Adjustable Steel Frame Formwork with thickness of 18mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

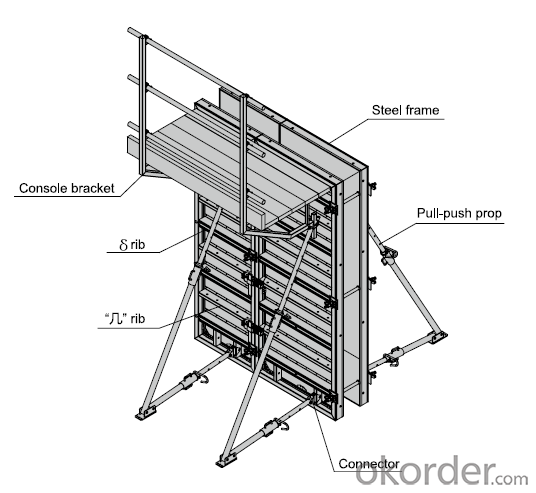

1. Structure of Steel Frame Formwork

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

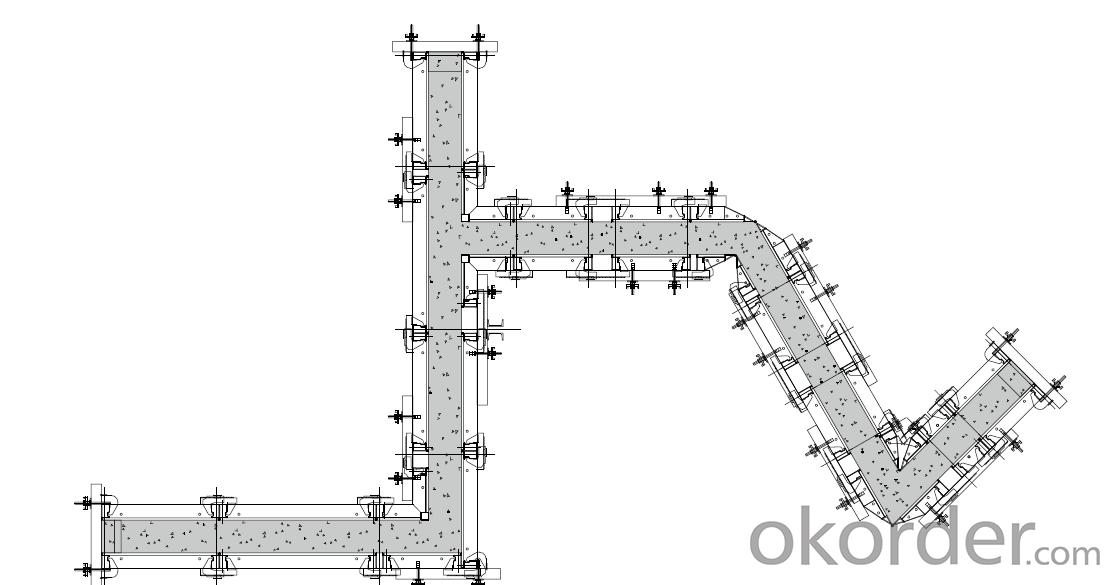

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of Steel Frame Formwork

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. Steel Frame Formwork Images

4. Steel Frame Formwork Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

5. FAQ of Steel Frame Formwork

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in Steel Frame Formwork , please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. Steel Frame Formwork cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of Steel Frame Formwork , we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: What are the key considerations for selecting the appropriate steel frame formwork system for tall structures?

- When selecting the appropriate steel frame formwork system for tall structures, there are several key considerations that need to be taken into account: 1. Load-bearing capacity: The formwork system must be able to withstand the weight of the concrete and other materials used in the construction of tall structures. It should have a high load-bearing capacity to ensure the safety and stability of the structure. 2. Flexibility and adjustability: Tall structures often have complex shapes and varying floor plans. The formwork system should be flexible and adjustable to accommodate these design variations. It should be able to adapt to different heights, angles, and curves to ensure accurate and precise construction. 3. Speed and efficiency: Construction of tall structures requires a fast and efficient formwork system to meet project deadlines. The selected system should be easy to install, dismantle, and move to different levels. It should also allow for quick pouring and curing of concrete to expedite the construction process. 4. Safety: Safety is of utmost importance in any construction project, especially in tall structures. The formwork system should have safety features such as guardrails, handrails, and non-slip surfaces to protect workers from falls and accidents. It should also provide adequate access and egress points to ensure safe movement of workers within the structure. 5. Durability and reusability: Tall structures often require multiple pours of concrete, so the formwork system should be durable enough to withstand repeated use without compromising its structural integrity. Additionally, it should be designed for easy dismantling, cleaning, and reassembly to minimize costs and waste. 6. Cost-effectiveness: Selecting a cost-effective formwork system is crucial for tall structures, as the project budget can be significantly impacted by the choice of formwork. The system should offer a good balance between quality, performance, and cost. It is important to consider not only the initial investment but also the long-term maintenance and reusability costs. By considering these key factors, project managers and engineers can select the most appropriate steel frame formwork system for tall structures, ensuring the efficient, safe, and successful completion of the construction project.

- Q: Does steel frame formwork require any specific reinforcement detailing?

- Yes, steel frame formwork does require specific reinforcement detailing. The reinforcement detailing is necessary to ensure the structural integrity and stability of the formwork system, especially during the pouring and curing of concrete. The reinforcement detailing includes the placement and spacing of steel bars, the size and type of reinforcement elements, and the connections between different components of the formwork system. Proper reinforcement detailing helps to distribute loads evenly, prevent potential cracks or failures, and enhance the longevity of the formwork.

- Q: Can steel frame formwork be used for curved or irregular shapes?

- Yes, steel frame formwork can be used for curved or irregular shapes. Unlike traditional timber formwork, steel frame formwork is more flexible and can be easily adjusted to accommodate various shapes and designs. The steel frames can be bent or adjusted to the desired curvature, allowing for the creation of curved or irregular structures. Additionally, the steel frames provide a sturdy and durable support system, ensuring the stability and integrity of the formwork during the construction process. This makes steel frame formwork an ideal choice for projects that involve curved or irregular shapes.

- Q: What are the common sizes of steel frame formwork panels?

- The common sizes of steel frame formwork panels vary depending on the specific construction project and the requirements of the concrete structure being built. However, there are a few standard sizes that are commonly used in the industry. One of the most common sizes for steel frame formwork panels is 1.2 meters by 2.4 meters (4 feet by 8 feet). This size is widely used and readily available, making it a popular choice for many construction projects. These panels are typically lightweight and easy to handle, making them suitable for a wide range of applications. Another common size for steel frame formwork panels is 1.5 meters by 3 meters (5 feet by 10 feet). These larger panels are often used for bigger concrete structures or projects that require a larger surface area to be covered. Despite their larger size, these panels are still relatively easy to handle and install. In addition to these standard sizes, custom sizes of steel frame formwork panels can also be manufactured to meet the specific needs of a construction project. This allows for greater flexibility and adaptability, ensuring that the formwork system can be tailored to the unique requirements of the concrete structure being built. It is important to note that the sizes mentioned above are just some of the common options available for steel frame formwork panels. The actual sizes used in a construction project will depend on various factors such as the design and dimensions of the concrete structure, the available space on the construction site, and the preferences of the construction team.

- Q: Can steel frame formwork be used for commercial buildings?

- Certainly, commercial buildings can make use of steel frame formwork. Steel frame formwork, widely employed in the construction sector, is an adaptable and enduring solution for diverse building types, including commercial edifices. Its remarkable strength and stability enable the development of towering structures and extensive commercial undertakings. Moreover, steel frame formwork exhibits great flexibility, effortlessly tailored to suit the distinctive specifications of various commercial building designs. Furthermore, it delivers a superior finish and can be repeatedly utilized, rendering it an economical option for commercial construction ventures.

- Q: How does steel frame formwork handle different types of concrete curing temperatures?

- Steel frame formwork is designed to handle different types of concrete curing temperatures effectively. Steel has excellent thermal conductivity, meaning it can quickly absorb and dissipate heat. This property allows the steel frame formwork to transfer the heat generated by the curing concrete evenly throughout the structure, preventing localized hot spots or temperature variations. In cases where the concrete requires high curing temperatures, such as in cold weather conditions, the steel frame formwork can be heated using various methods like electric heating coils or steam pipes. This ensures that the concrete maintains the optimal temperature for proper curing, preventing issues like delayed strength development or reduced durability. On the other hand, in situations where the concrete needs to be cured at lower temperatures, the steel frame formwork can be cooled using techniques like water circulation or air conditioning. This helps in preventing excessive heat buildup, which can cause thermal cracking or other structural problems in the concrete. Overall, steel frame formwork provides a reliable and efficient solution for handling different types of concrete curing temperatures. Its thermal properties allow for precise control and management of temperature during the curing process, ensuring that the concrete achieves the desired strength and durability characteristics.

- Q: Can steel frame formwork be used for both insulated and non-insulated wall construction?

- Yes, steel frame formwork can be used for both insulated and non-insulated wall construction. The steel frame provides a strong and stable structure for pouring and shaping concrete, regardless of whether insulation is required or not.

- Q: Can steel frame formwork be used in projects with limited budget constraints?

- Yes, steel frame formwork can be used in projects with limited budget constraints. While steel frame formwork may have a higher initial cost compared to other types of formwork, it offers several advantages that can offset this expense. Firstly, steel frame formwork is highly durable and can be reused multiple times, making it cost-effective in the long run. Unlike traditional timber formwork, steel frame formwork does not warp, shrink, or absorb moisture, ensuring consistent and accurate concrete shapes and dimensions. This durability also eliminates the need for frequent repairs or replacements, reducing maintenance costs. Furthermore, steel frame formwork allows for faster construction due to its ease of assembly and disassembly. This not only saves time but also reduces labor costs. Additionally, the precise and rigid nature of steel frame formwork ensures high-quality finishes, minimizing the need for additional surface treatments or rectifications. Moreover, steel frame formwork offers versatility in design, allowing for a wide range of shapes and sizes to be achieved. This flexibility eliminates the need for custom-made formwork, which can be costly, and provides cost savings in terms of material usage. Lastly, steel frame formwork can be rented or leased, providing a more budget-friendly option for projects with limited financial resources. Renting formwork allows for cost-sharing among multiple projects and eliminates the need for upfront capital investment. In conclusion, while steel frame formwork may have a higher initial cost, its durability, speed of construction, versatility, and rental options make it a viable choice for projects with limited budget constraints.

- Q: Can steel frame formwork be used for the construction of underground structures?

- Yes, steel frame formwork can be used for the construction of underground structures. Steel frame formwork is a versatile and strong construction material that can withstand the pressure and load of the surrounding earth. It provides stability and support during the pouring and curing process of concrete, ensuring that the structure is built to the required specifications. Steel frame formwork also allows for easy assembly and disassembly, making it suitable for the complex and confined spaces often found in underground construction. Additionally, steel frame formwork can be reused multiple times, making it a cost-effective and sustainable solution for underground structures. Overall, steel frame formwork is a reliable and efficient choice for the construction of underground structures.

- Q: What are the considerations for selecting the appropriate formwork for different concrete placements?

- When selecting the appropriate formwork for different concrete placements, there are several considerations that need to be taken into account. These considerations include: 1. Type of concrete placement: The type of concrete placement, such as vertical walls, slabs, columns, or beams, will influence the formwork selection. Each type requires specific formwork systems that can accommodate the required shape and size of the concrete structure. 2. Load capacity: The formwork must be able to withstand the weight and pressure exerted by the concrete during pouring and curing. It is essential to choose a formwork system that has the appropriate load capacity for the specific concrete placement to ensure safety and structural integrity. 3. Duration of use: The duration for which the formwork will be in use is another important consideration. If the formwork will be used for a short period, a temporary formwork system such as timber or plywood may be suitable. However, for long-term projects or when multiple pours are required, more durable and reusable formwork systems like steel or aluminum may be preferable. 4. Surface finish requirements: The desired surface finish of the concrete also affects the choice of formwork. If a smooth and uniform finish is required, formwork materials that have a smooth surface or can be easily coated with a release agent may be necessary. On the other hand, if a textured or patterned finish is desired, formwork materials that can accommodate such designs may be needed. 5. Cost-effectiveness: The cost of formwork materials and installation should be considered in relation to the overall project budget. Different types of formwork systems have varying costs, and it is important to select a system that is cost-effective while still meeting the project requirements. 6. Availability and accessibility: The availability and accessibility of the formwork materials and equipment should also be considered. It is important to choose formwork systems that are readily available in the local market and can be easily transported and assembled on-site. 7. Environmental considerations: The environmental impact of the formwork materials is another factor to be considered. Choosing sustainable and eco-friendly options, such as formwork materials made from recycled materials or those that can be recycled after use, can contribute to a more environmentally conscious construction process. By carefully considering these factors, contractors and engineers can select the appropriate formwork for different concrete placements, ensuring optimal construction efficiency, safety, and quality.

Send your message to us

SF120 Adjustable Steel Frame Formwork with thickness of 18mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 10000000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords