Steel Frame Formwork for Wall and Column and Beam Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specification

1. CMAX Steel Frame Formwork Description

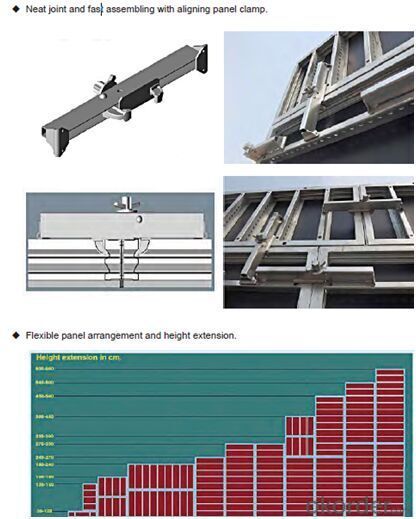

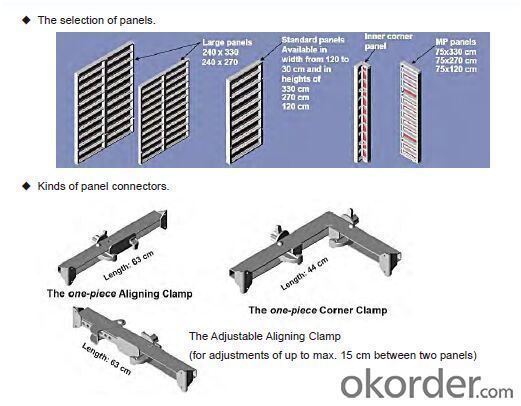

CMAX Steel Frame Formwork System is designed to reduce material quantity, with adjustable flexiable sizes of frame, the 140 series steel formwork is a heavy-bearing steel frame formwork works with steel frame, plywood and lock. It is widely used in various projects and reduce cost by using standardized sizes of forms as well. The concrete surface is quite clean.

2. Specifications of Steel Frame Formwork

- Max. Concrete pressure: 80KN/m2.

- Hot-dip galvanized steel frame.

- The thickness of plywood is 18mm & the panel is 350px..

- Compatibility with Hunnebeck Manto system due to similar edge profile.

- We can special design according to any requirements.

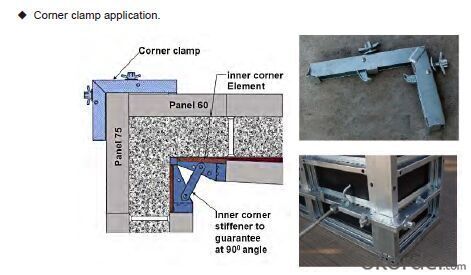

3. CMAX Steel Frame Formwork Images

4. FAQ of Steel Frame Formwork

1) What can we do for you?

- We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

- We can provide you the professional design team.

- We can provide fashionable and newest styles for you.

- We can design the artwork for you.

- Please feel free to customize.

2) What promises can be done by us?

- If interested in Timber-beam Formwork, please feel free to write us for any QUOTE.

- If printing required, please advise asap because the whole set need much more time to complete.

- Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about the package and shipping time?

- Packing: As Customer's Requirements

- Shipping: We have various shipping ways for our customers, such as express, by air/ sea etc.

- Shipping time: Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

- Q: Are there any limitations on the height of structures that can be constructed using steel frame formwork?

- The construction of structures using steel frame formwork is subject to certain limitations when it comes to height. The primary factors that influence these limitations include the design, engineering considerations, and the capabilities of the steel frame formwork system being utilized. A crucial aspect that can restrict the height is the capacity of the steel frame formwork to bear loads. It must be capable of supporting the weight of the concrete as well as any additional loads such as construction equipment or workers. Should the height surpass the formwork's load-bearing capacity, it may lead to structural instability and potential collapse. Furthermore, the stability and rigidity of the steel frame formwork system play a vital role in determining the maximum height. As the height increases, the formwork system must withstand lateral forces, wind loads, and other external factors that can impact the structure's stability. Failure to account for these forces in the formwork's design compromises the construction's safety and integrity. In addition, the availability of suitable equipment and technology can impose restrictions on the height of structures constructed using steel frame formwork. Taller structures may necessitate specialized equipment, such as high-capacity cranes or lifting systems, for the assembly and dismantling of the formwork. If such equipment is unavailable or impractical, it limits the height achievable with steel frame formwork. Lastly, local building codes and regulations also dictate the maximum height of structures. These regulations exist to guarantee the safety and stability of buildings and prevent potential risks to the surrounding environment. It is imperative to adhere to these regulations and obtain appropriate permits when constructing tall structures using steel frame formwork. To conclude, while steel frame formwork offers versatility and strength in construction, there are limitations on the height of structures that can be constructed using this system. Factors such as load-bearing capacity, stability, equipment availability, and local regulations determine the maximum achievable height. It is crucial to consult experienced engineers and adhere to safety guidelines to ensure the successful construction of tall structures using steel frame formwork.

- Q: What types of concrete structures can be constructed using steel frame formwork?

- Steel frame formwork is a versatile construction method that allows for the construction of various types of concrete structures. Some examples of concrete structures that can be constructed using steel frame formwork include: 1. High-rise buildings: Steel frame formwork provides the necessary support and stability required for constructing tall structures. It allows for the construction of multiple floors by providing a strong framework that can withstand the weight and pressure exerted by the concrete. 2. Bridges: Steel frame formwork can be used to construct concrete bridges of different spans and sizes. The steel frames provide the necessary support for pouring and curing the concrete, ensuring the strength and stability of the bridge structure. 3. Tunnels: Steel frame formwork can be used to construct concrete tunnels, such as those used in transportation infrastructure projects. The steel frames are designed to withstand the pressure exerted by the surrounding soil and provide a stable formwork for pouring and curing the concrete. 4. Retaining walls: Steel frame formwork is commonly used for constructing concrete retaining walls. These structures are designed to hold back soil and prevent erosion. The steel frames provide the necessary support for pouring and curing the concrete, ensuring the stability and durability of the retaining wall. 5. Water tanks: Steel frame formwork can be used to construct concrete water tanks for storing potable water or other liquids. The steel frames provide the necessary support and shape for pouring and curing the concrete, resulting in a strong and watertight structure. 6. Industrial structures: Steel frame formwork is also suitable for constructing various types of industrial structures, such as factories, warehouses, and power plants. The steel frames provide the necessary support and stability for pouring and curing the concrete, ensuring the strength and durability of the structures. Overall, steel frame formwork is a versatile construction method that can be used to construct a wide range of concrete structures. Its strength, stability, and flexibility make it an ideal choice for various construction projects.

- Q: ANSYS steel frame structure modeling, commonly used in size, density, Poisson's ratio is much better? Help。

- Steel structure with a long time carbon structural steel, the size of the size of the steel you actually use

- Q: How does steel frame formwork help in reducing concrete segregation?

- Steel frame formwork helps in reducing concrete segregation by providing a strong and rigid structure that holds the concrete in place during the pouring and curing process. The steel frame formwork prevents the concrete from flowing or separating, ensuring that the aggregate and cement are uniformly distributed throughout the mixture. This helps to minimize the risk of concrete segregation, which can lead to an uneven and weaker final structure.

- Q: How does steel frame formwork affect the overall sustainability certifications of a building?

- Steel frame formwork can significantly impact the overall sustainability certifications of a building in a positive way. One of the key aspects of sustainability is the efficient use of resources, and steel frame formwork excels in this area. Steel is a highly durable and recyclable material, meaning that it can be used repeatedly without compromising its structural integrity. This reduces the need for new materials, minimizing the environmental impact associated with construction. Additionally, steel frame formwork offers enhanced efficiency during the construction process. It allows for faster assembly and disassembly, reducing the time required for construction and minimizing disruption to the surrounding environment. This can lead to reduced energy consumption, as the construction phase is completed more quickly. Furthermore, steel frame formwork provides excellent strength and stability, enabling the construction of taller and larger buildings. This can optimize land use and reduce the footprint of the building, contributing to a more sustainable urban environment. Moreover, steel is resistant to fire, pests, and natural disasters, ensuring the longevity and safety of the building. This reduces the need for frequent repairs and replacements, leading to lower maintenance costs and less waste generation. In terms of sustainability certifications, such as LEED (Leadership in Energy and Environmental Design), steel frame formwork can contribute to earning points in various categories. These certifications often prioritize energy efficiency, materials and resources, and innovation in design. Steel frame formwork can help achieve these goals by reducing energy consumption during construction, utilizing recycled materials, and providing a durable and long-lasting structure. Overall, steel frame formwork positively affects the sustainability certifications of a building by promoting resource efficiency, reducing environmental impact, enhancing construction efficiency, and contributing to the durability and safety of the structure.

- Q: How does steel frame formwork ensure accurate dimensions and alignment?

- Steel frame formwork ensures accurate dimensions and alignment through its rigid and sturdy structure. The steel frames are designed and manufactured with precision, ensuring that they are perfectly straight and of the correct dimensions. This allows for the formation of uniformly sized and aligned concrete structures. The steel frames are assembled together to create a robust framework that provides stability and support during the concrete pouring process. The frames are securely fixed in place, preventing any movement or shifting during the casting of the concrete. This eliminates the risk of any dimensional variations or misalignments in the final structure. Additionally, steel formwork allows for precise adjustment and leveling. The frames are equipped with adjustable props, wedges, and clamps, which can be used to fine-tune the position and alignment of the formwork. This enables the construction team to achieve accurate dimensions and alignment as per the project specifications. The steel frame formwork system also ensures dimensional accuracy by providing a smooth and seamless surface finish. The steel panels are constructed with high-quality materials that prevent any warping or bending, resulting in a consistent and even surface. This eliminates the need for excessive plastering or finishing work, further enhancing the accuracy of the dimensions and alignment. Overall, the use of steel frame formwork in construction projects guarantees accurate dimensions and alignment by providing a strong and stable framework, allowing for precise adjustments, and delivering a smooth surface finish. This ensures that the final concrete structures meet the required specifications and achieve the desired level of accuracy.

- Q: How does steel frame formwork handle the placement of concrete in structures with complex geometries or irregular shapes?

- Steel frame formwork is a versatile and efficient solution when it comes to handling the placement of concrete in structures with complex geometries or irregular shapes. This type of formwork system offers several advantages that make it suitable for such scenarios. Firstly, steel frame formwork provides a high degree of flexibility in terms of adjusting to different shapes and configurations. The modular nature of steel frames allows for easy customization and adaptation to accommodate complex geometries. This enables the construction of structures with irregular shapes, curves, and varying angles. Additionally, steel frame formwork offers excellent strength and stability. The rigid steel frames provide a solid support structure, ensuring that the formwork maintains its shape during the pouring and curing of concrete. This stability is crucial when dealing with complex geometries, as it prevents any deformations or misalignments that could compromise the structure's integrity. Moreover, steel frame formwork is highly durable and can withstand the pressure exerted by the concrete during pouring and curing. This durability is essential when dealing with complex structures, as it ensures that the formwork remains intact and can handle the weight and force of the concrete. Furthermore, steel frame formwork allows for easy and efficient installation and dismantling processes. The modular components can be quickly assembled and disassembled, enabling smooth transitions between different sections and shapes. This saves time and labor costs, making it a cost-effective solution for projects with complex geometries. In conclusion, steel frame formwork is an ideal choice when handling the placement of concrete in structures with complex geometries or irregular shapes. Its flexibility, strength, durability, and ease of installation make it a reliable and efficient solution for achieving the desired concrete structure with precision and accuracy.

- Q: Does steel frame formwork require any specific lifting or hoisting equipment?

- The installation and removal of steel frame formwork typically necessitate the use of specific lifting or hoisting equipment. Given the considerable weight and size of steel frames, it becomes imperative to utilize specialized machinery like cranes or forklifts to hoist and position the formwork appropriately. These lifting apparatuses ensure the secure and efficient handling of the steel frames, enabling accurate alignment and securement for concrete pouring. Similarly, during the dismantling process, hoisting equipment is employed to eliminate the formwork without causing any harm or injury. In conclusion, the utilization of specific lifting or hoisting equipment is crucial for the correct installation and removal of steel frame formwork.

- Q: Are there any specific considerations for using steel frame formwork in earthquake-prone areas?

- Yes, there are specific considerations for using steel frame formwork in earthquake-prone areas. Firstly, it is important to ensure that the steel frame formwork is designed and constructed to meet the seismic design requirements of the specific area. This includes considering factors such as the expected level of seismic activity, the soil conditions, and the building codes and regulations in place. Steel frame formwork should be designed to have sufficient strength and stiffness to withstand the seismic forces that may be exerted on it during an earthquake. This may involve using thicker steel sections, reinforcement, or additional bracing to enhance the structural integrity and stability of the formwork system. In earthquake-prone areas, it is also crucial to establish a secure connection between the steel frame formwork and the supporting structure. This can be achieved through proper anchorage and tie-down systems that are designed to resist the lateral forces generated by an earthquake. Adequate attention should be given to the detailing and installation of these connections to ensure their effectiveness. Additionally, it is recommended to use high-quality steel and ensure proper maintenance and inspection of the steel frame formwork. Steel with a high tensile strength and good ductility can provide better resistance to the dynamic forces experienced during an earthquake. Regular inspection and maintenance can help identify any potential issues or damage, allowing for timely repairs or replacements to maintain the formwork's integrity. Finally, it is crucial to consider the safety of workers during the construction process in earthquake-prone areas. This may involve implementing additional safety measures such as providing proper training on earthquake response and evacuation procedures, ensuring the availability of safe zones during seismic events, and using protective equipment to minimize the risk of injuries. Overall, using steel frame formwork in earthquake-prone areas requires careful consideration of design, construction, connection, material quality, maintenance, and worker safety. It is essential to consult with experienced engineers and adhere to local building codes and regulations to ensure the safety and stability of the construction in such areas.

- Q: The main beam is the beam that is connected to both ends of the beam In the main frame, the cross beam of the vertical and horizontal cross, why should it be connected at the intersection?Do you need a connection plate for welding? Directly to the steel repair, plug welding can not?

- Welding and high-strength bolt connections can be

Send your message to us

Steel Frame Formwork for Wall and Column and Beam Construction

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 10 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords