New Invented Plastic Formworks in Construction Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

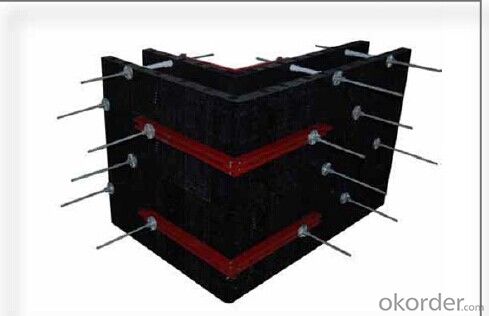

1. Structure of plastic formworks

There is a prizing part designed in the corner, which can help to position and remove formwork easily.

The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

2. Main Features of plastic formworks

Light weight

High strength

High standardized system

Easy connection with adjustable steel clamp

Convenient and fast corner formwork

Flexible to assemble and application

3. plastic formworks Images

4. plastic formworks Specification

-The steel frame formwork is plywood covered with hollow steel. The plywood is 18 mm thick.

-The frame is highly strengthened, and the wall formwork can bear lateral pressure 60 KN/m2 while the column formwork can bear 80 KN/m2.

-As a standardized system, it is flexible to assemble , wood batten can be filled to satisfy the need f of non-standard size.

-The adjustable steel clamp is convenient to use, and can hold tightly.

-There is a prizing part designed in the corner, which can help to position and remove formwork easily.

-The plywood is screwed on from the back when connecting frame and plywood, so the surface of the finished concrete is perfect.

-The formwork series are a complete system with a full set of accessories, and can be set up flexibly according to project demand.

5. FAQ of plastic formworks

1) What can we do for you?

.We can ensure the quality of the vinyl banner and avoid extra expenses for customers.

.We can provide you the professional design team.

.We can provide fashionable and newest styles for you.

.We can design the artwork for you.

. Please feel free to customize.

2) What promises can be done by us?

. If interested in plastic formworks, please feel free to write us for any QUOTE.

. If printing required, please advise asap because the whole set need much more time to complete.

. Please DO check goods when courier knocks your door and contact us asap if any issue.

3) What about of our after-sale service?

. Response will be carried out in 24hours after receiving any complain or request.

. plastic formworks cost can be refund after order is confirmed.

. If the products are not based on the requirements, there will be the relevant compensations made for you.

4) What about the package and shipping time?

.Packing: As Customer's Requirements

.Shipping: We have various shipping ways for our customers, such as express which including TNT, DHL, FEDEX, UPS, EMS, etc. ; by air/ sea, and we are VIP of these express.

.Shipping time:

Normally small orders, it just 10-15 business days to arrive your hand; When comes to the customs declaration, it may need 7 days.

Other mass qty of plastic formworks, we send them out by sea or by air to sea port or air port to save some shipping freight for our customers. By ocean, it may need 45~60days, by air, it may need 25~40days.

- Q: What types of concrete structures can be constructed using steel frame formwork?

- Steel frame formwork can be used to construct a wide range of concrete structures, including but not limited to buildings, bridges, dams, tunnels, retaining walls, and industrial structures.

- Q: How does steel frame formwork handle different types of concrete curing temperatures?

- Steel frame formwork is designed to handle different types of concrete curing temperatures effectively. Steel has excellent thermal conductivity, meaning it can quickly absorb and dissipate heat. This property allows the steel frame formwork to transfer the heat generated by the curing concrete evenly throughout the structure, preventing localized hot spots or temperature variations. In cases where the concrete requires high curing temperatures, such as in cold weather conditions, the steel frame formwork can be heated using various methods like electric heating coils or steam pipes. This ensures that the concrete maintains the optimal temperature for proper curing, preventing issues like delayed strength development or reduced durability. On the other hand, in situations where the concrete needs to be cured at lower temperatures, the steel frame formwork can be cooled using techniques like water circulation or air conditioning. This helps in preventing excessive heat buildup, which can cause thermal cracking or other structural problems in the concrete. Overall, steel frame formwork provides a reliable and efficient solution for handling different types of concrete curing temperatures. Its thermal properties allow for precise control and management of temperature during the curing process, ensuring that the concrete achieves the desired strength and durability characteristics.

- Q: What are the key considerations for selecting the appropriate steel frame formwork system for repetitive use?

- When selecting the appropriate steel frame formwork system for repetitive use, there are several key considerations that need to be taken into account. Firstly, the durability and quality of the steel frame formwork system is of utmost importance. Since it will be used repetitively, it needs to withstand the constant wear and tear without compromising its integrity. The steel used should be of high quality and have the necessary strength and toughness to withstand the repetitive loads. The ease of assembly and disassembly is another crucial factor to consider. The formwork system should be designed in such a way that it can be easily assembled and disassembled without requiring excessive time or effort. This will not only save time during construction but also make it more efficient for repetitive use. Additionally, the adjustability and flexibility of the formwork system should be considered. It should be capable of accommodating different sizes and shapes of concrete structures. This adaptability is crucial as it allows for versatility in construction projects and ensures that the formwork system can be reused for various purposes. Furthermore, the safety features of the steel frame formwork system should be thoroughly evaluated. It should have adequate bracing and support to ensure stability during the concrete pouring process. It should also have proper guardrails and safety measures in place to protect workers from potential hazards. The cost-effectiveness of the formwork system is another key consideration. While it is important to select a reliable and durable system, it is equally important to ensure that it offers value for money. Comparing the initial investment with the expected lifespan and number of reuses can help determine the cost-effectiveness of the system. Lastly, the availability of technical support and maintenance services should be considered. It is essential to choose a manufacturer or supplier that provides adequate technical support and maintenance services throughout the lifespan of the formwork system. This ensures that any issues or repairs can be addressed promptly, minimizing downtime and maximizing the system's longevity. By considering these key factors, one can select the appropriate steel frame formwork system that is durable, easy to assemble and disassemble, adjustable, safe, cost-effective, and backed by reliable technical support and maintenance services.

- Q: What are the different types of safety systems used with steel frame formwork?

- There are several types of safety systems commonly used with steel frame formwork, including guardrails, safety nets, edge protection systems, fall arrest systems, and personal protective equipment (PPE) such as helmets, harnesses, and safety goggles. These systems are designed to prevent falls, provide physical barriers, and ensure the safety of workers during construction activities involving steel frame formwork.

- Q: What is steel wood formwork?

- 3, can be repeatedly used.4, after the release effect is very good.

- Q: Can steel frame formwork be used for concrete stairs?

- Yes, steel frame formwork can be used for concrete stairs. Steel frame formwork is a versatile and durable system that can be customized to suit various construction needs, including the construction of stairs. It offers several advantages for constructing concrete stairs, such as high strength, stability, and the ability to create complex shapes and designs. Steel frame formwork provides a reliable and efficient solution for constructing concrete stairs, ensuring a strong and long-lasting structure.

- Q: Can steel frame formwork be used for the construction of sports facilities?

- Certainly! Steel frame formwork is a viable option for building sports facilities. Renowned for its robustness and longevity, this construction method is suitable for a wide range of structures, including sports facilities. Its stability enables it to bear heavy loads and endure repetitive use, making it an optimal choice for sports facilities that experience high foot traffic and require long-lasting construction. Moreover, steel frame formwork can be easily assembled and disassembled, facilitating efficient construction processes and potential future modifications or expansions of the sports facility. All in all, due to its strength, durability, and flexibility, steel frame formwork is a dependable option for constructing sports facilities.

- Q: Can steel frame formwork be used in areas with limited site preparation?

- Yes, steel frame formwork can be used in areas with limited site preparation. Steel frame formwork is versatile and can be designed and adjusted to fit various site conditions, including areas with limited site preparation. Its rigid structure allows it to withstand uneven ground or limited access, making it suitable for such areas. Additionally, steel frame formwork can be easily assembled and disassembled, which further facilitates its use in areas with limited site preparation.

- Q: How does steel frame formwork accommodate for different concrete mix designs?

- Steel frame formwork offers great versatility as it can easily cater to different concrete mix designs. The steel frames are intelligently designed to allow for adjustments and modifications that meet the specific requirements of each concrete mix. To begin with, the steel formwork can be easily adjusted to accommodate various concrete mix designs by modifying the size and shape of the formwork panels. This can be achieved by either adding or removing sections of the steel frames or by utilizing adjustable panels that can be resized accordingly. These alterations guarantee that the formwork aligns perfectly with the dimensions and specifications of the concrete mix. Furthermore, steel frame formwork provides flexibility in terms of the desired surface finish for different concrete mix designs. The formwork can be adapted to incorporate a range of surface treatments like smooth finishes, textured finishes, or patterned finishes. This adaptability allows for different concrete mix designs to achieve the desired aesthetic and functional requirements. Additionally, steel frame formwork can effectively accommodate diverse concrete mix designs by integrating specific features or reinforcements. For instance, if a concrete mix necessitates additional support or reinforcement, the steel frames can be modified to include additional beams, braces, or tie rods. These reinforcements guarantee the structural integrity and stability of the formwork, enabling it to withstand the pressures and forces exerted by various concrete mix designs. In conclusion, steel frame formwork proves to be an incredibly flexible solution that easily caters to different concrete mix designs. The adjustability of the formwork panels, the flexibility in surface finish, and the ability to incorporate specific features or reinforcements ensure that the formwork is compatible with various concrete mix designs and can accurately meet the specific requirements of each project.

- Q: How does steel frame formwork ensure proper anchoring to the ground?

- Steel frame formwork ensures proper anchoring to the ground through a combination of factors. Firstly, the steel frame itself is designed with sturdy anchor points and connection mechanisms that help secure it firmly to the ground. Additionally, the formwork is often supported by vertical supports such as props or scaffolding, which further enhance its stability and prevent any movement. This ensures that the formwork remains in place during the concrete pouring and curing process, ultimately resulting in a properly anchored structure.

Send your message to us

New Invented Plastic Formworks in Construction Industry

- Loading Port:

- Shanghai

- Payment Terms:

- TT or LC

- Min Order Qty:

- 1 m²

- Supply Capability:

- 100000 m²/month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords