Continuous Casting Steel Billet Q275/235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

STEEL BILLET

1.Structure of Steel Billet

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

2.Main Features of Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

3.Processing of Steel Billet

Steel billets are considered fresh and raw, and they must undergo a series of manufacturing processes before they can be used for various purposes. Billets are made by means of freezing molten liquid, and are later exposed to extremely low temperatures in order to allow the metal to take shape and solidify in chemical structure. The temperature manipulates the metal's physical properties, and tones its strength and durability. The subsequent processes provide the metal's curved mold design so that it can fit the allotted space provided by other machines, which complete the finishing procedures.

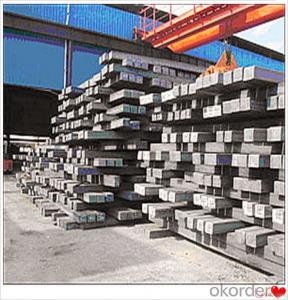

4.Steel Billet Images

5.Usage of Steel Billet

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

6. Steel Billet Specification

Hot rolled billet steel

Size: 50x50mm-180x180mm

Steel Grade: 3SP, 5SP,Q195,Q235,Q255,Q275 Length:3m-12m

MOQ: 1000MT/size

Payment term: TT or LC

Packing: in bulk , bundle

Shipment: by container , bulk vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: 15-30 days after the deposit

Loading port:Tianjin, or other port China

Origin :China

Inspection:Third party inspection before loading.

7.FAQ

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3)If there’s something wrong with the quality of the products, how do we return the goods?

We promise you the quality will be the same as the samples you confirmed. If there’s something wrong with the quality of the products, please send back sample from the shipment goods to us and let us know the quantity, then we will investigate in our work shop. If it is our problem, we will offer you discount or replacements for free.

- Q: How are steel billets used in the manufacturing of power generation equipment?

- The manufacturing of power generation equipment relies heavily on steel billets, which are indispensable raw materials. These billets, cast from molten steel, take the form of large rectangular or square-shaped semi-finished steel products. They are then either hot rolled or forged to achieve their final shape. Within the power generation equipment context, steel billets are primarily employed in the construction of turbine components, such as turbine blades and rotors. Additionally, they are used in the fabrication of generator casings and other structural parts. The exceptional strength and durability of steel make it the ideal material for these critical components, which must endure high temperatures, pressure, and rotational forces. The process commences with the careful selection of a suitable grade of steel billet, based on the specific requirements of the power generation equipment. Subsequently, the billets are heated to an appropriate temperature and then forged or hot rolled to shape them as desired. This process necessitates precise techniques, such as machining, cutting, and shaping, to achieve the required dimensions and surface finish. Once the turbine components and other parts are formed from the steel billets, they undergo further treatments, including heat treatment, surface coating, and machining. These treatments aim to enhance their mechanical properties and ensure compatibility with the power generation system. Ultimately, the final products are assembled into power generation equipment, which may consist of gas turbines, steam turbines, wind turbine components, or generator sets. Steel billets play a critical role in the manufacturing of power generation equipment as they provide the necessary strength, durability, and performance required for efficient and reliable operation. The quality and precision involved in the production of steel billets directly impact the overall performance and lifespan of the power generation equipment, making them an essential component in the industry.

- Q: What are the different types of defects that can occur during casting of steel billets?

- During the casting of steel billets, several types of defects can occur, affecting the quality and integrity of the final product. Some common defects include: 1. Shrinkage: Shrinkage defects occur when the metal cools and solidifies unevenly, causing voids or shrinkage cavities in the billet. This can weaken the structure and reduce its overall strength. 2. Porosity: Porosity refers to the presence of trapped gas or air bubbles in the billet. It can occur due to improper gating or venting, inadequate control of the pouring temperature, or the presence of impurities in the molten metal. Porosity can reduce the billet's mechanical properties and make it more susceptible to failure. 3. Inclusions: Inclusions are non-metallic materials, such as oxides, sulfides, or refractory particles, that get trapped in the billet during casting. These inclusions can weaken the metal, leading to reduced ductility, increased brittleness, and decreased resistance to fatigue or corrosion. 4. Cold shuts: Cold shuts happen when two streams of molten metal fail to fuse properly during casting, resulting in a visible line or seam in the billet. Cold shuts can weaken the billet and cause it to fail under stress. 5. Hot tearing: Hot tearing occurs when the solidifying metal is restrained from contracting, leading to localized cracking or tearing. It usually happens due to high thermal stresses or inadequate feeding of the metal during solidification. Hot tearing can significantly affect the billet's structural integrity. 6. Misruns: Misruns are defects that occur when the molten metal fails to fill the entire mold cavity completely. This can happen due to inadequate pouring temperature, improper gating or venting, or insufficient fluidity of the metal. Misruns can result in incomplete, undersized, or malformed billets with reduced mechanical properties. 7. Surface defects: Surface defects include surface cracks, scabs, or surface roughness that can occur during the solidification or cooling process. These defects can lead to increased rejection rates, reduced machinability, and compromised surface finish of the billet. It is crucial to identify and minimize these defects during the casting process to ensure the production of high-quality steel billets with the desired mechanical properties and dimensional accuracy.

- Q: How are steel billets used in the manufacturing of telecommunications equipment?

- Telecommunications equipment manufacturing relies heavily on steel billets, which serve as a crucial component. These billets act as the raw material that undergoes shaping and transformation to create various components used in telecommunications infrastructure. Primarily, steel billets are used in the production of towers and masts, providing the necessary support for antennas and other transmitting and receiving equipment. To ensure strength and stability, the billets are melted and then forged or rolled into the desired shape, forming the structural members of these towers. Moreover, steel billets are also essential in the manufacturing of cable trays and cable management systems. These components play a crucial role in organizing and protecting the extensive network of cables used in telecommunications systems. By processing and fabricating the billets into cable trays, brackets, and supports, a robust and durable solution is provided for managing the complex web of cables. Furthermore, steel billets find application in the production of enclosures and cabinets that house sensitive telecommunications equipment. These enclosures safeguard the equipment from environmental factors like dust, moisture, and temperature fluctuations. By molding and shaping the steel billets into the desired size and design, a sturdy and secure enclosure is achieved. In conclusion, the role of steel billets in telecommunications equipment manufacturing cannot be overstated. Whether it is for towers and masts, cable trays, or enclosures, these billets lay the foundation and ensure the structural integrity necessary for the reliable operation of telecommunications infrastructure.

- Q: How are steel billets measured and classified?

- Steel billets are typically measured and classified based on their dimensions, weight, and chemical composition. The dimensions of a billet, such as its length, width, and height, are measured to determine its size. The weight of the billet is determined by weighing it, either using a scale or by calculating its volume and density. Additionally, the chemical composition of the steel, including the percentage of elements like carbon, manganese, and silicon, is analyzed to classify the billet based on its grade or specific properties.

- Q: Are steel billets used in the production of sporting goods?

- Yes, steel billets are commonly used in the production of sporting goods. They are often utilized to create various components such as the shafts of golf clubs or the frames of bicycles. Steel billets provide durability and strength to these sporting goods, making them suitable for intense physical activity.

- Q: What are the main challenges in the distribution of steel billets?

- The distribution of steel billets faces several challenges that can impact the overall efficiency and effectiveness of the process. Some of the main challenges include: 1. Logistics and transportation: Steel billets are heavy and bulky, requiring specialized equipment and handling. The transportation of these materials can be challenging, especially in remote areas or regions with poor infrastructure. The coordination of transportation modes, scheduling, and ensuring timely delivery can be a complex task. 2. Storage and inventory management: Steel billets often need to be stored for a certain period of time before they are processed or further distributed. Proper storage facilities with adequate capacity and appropriate conditions, such as temperature control and protection from moisture, are crucial. Managing inventory levels to avoid excess or shortage is also a key challenge. 3. Quality control: Ensuring the quality of steel billets throughout the distribution process is essential. Any damage or contamination during handling or transportation can affect the properties and performance of the final steel products. Implementing strict quality control measures, inspections, and monitoring processes is crucial to maintain the desired quality standards. 4. Market fluctuations and demand forecasting: The steel industry is highly influenced by market fluctuations and demand volatility. Accurate demand forecasting can be challenging due to various factors such as economic conditions, construction activities, and geopolitical events. Failure to predict demand accurately can result in excess inventory or stockouts, leading to financial losses. 5. Environmental regulations and sustainability: The steel industry is under increasing pressure to reduce its environmental impact and embrace sustainable practices. Compliance with environmental regulations, such as emissions control and waste management, can present challenges in distribution. Implementing eco-friendly transportation methods and exploring sustainable packaging options can help address these challenges. 6. Global competition and pricing: The distribution of steel billets is affected by global competition and pricing pressures. Steel producers and distributors must constantly analyze and adapt to market trends, competitor behavior, and price fluctuations. Maintaining competitive pricing while ensuring profitability can be a significant challenge in the steel billet distribution business. Overcoming these challenges requires coordination among various stakeholders in the supply chain, including steel manufacturers, distributors, logistics providers, and end-users. Continuous improvement, technological advancements, and effective communication are essential to mitigate these challenges and optimize the distribution of steel billets.

- Q: What are the main challenges in the marketing of steel billets?

- The main challenges in the marketing of steel billets can be attributed to several factors. Firstly, one of the major challenges is the highly competitive nature of the steel industry. There are numerous steel manufacturers and suppliers globally, which creates a saturated market. This leads to a constant struggle for market share, as companies need to differentiate themselves from their competitors and maintain a strong presence. Secondly, fluctuations in global demand and supply of steel can pose significant challenges. Steel billets are primarily used as raw material for various industries, including construction, automotive, and manufacturing. Any changes in these industries' demand can directly impact the demand for steel billets. Therefore, marketing strategies need to be adaptable and responsive to market dynamics to ensure a stable customer base. Additionally, pricing is another critical challenge. Steel billets are often subject to price volatility due to factors such as raw material costs, energy prices, and global economic conditions. Companies must constantly monitor and analyze these factors to set competitive prices while maintaining profitability. Moreover, the marketing of steel billets requires a thorough understanding of the target market's needs and preferences. Different industries may require specific qualities and specifications in their billets, such as size, composition, or surface finish. Companies must invest in research and development to meet these requirements and effectively communicate the advantages of their products to potential customers. Another challenge lies in establishing and maintaining strong relationships with customers. Steel billets are typically sold through long-term contracts and relationships built on trust and reliability. Building and nurturing these relationships require consistent quality, on-time delivery, and excellent customer service. Lastly, environmental sustainability is an emerging challenge in the marketing of steel billets. With increasing environmental regulations and growing consumer awareness, companies need to position themselves as environmentally responsible and promote sustainable practices throughout their value chain. In conclusion, the marketing of steel billets faces challenges related to intense competition, demand-supply dynamics, pricing, market understanding, customer relationships, and environmental sustainability. Overcoming these challenges requires strategic planning, continuous adaptation, and a customer-centric approach.

- Q: What are the specifications for alloy steel billets used in the defense industry?

- The specifications for alloy steel billets used in the defense industry vary depending on the specific application and requirements of each project. However, there are certain common specifications that are typically followed. Firstly, the alloy steel billets used in the defense industry must meet stringent material standards and be certified to specific military or industry specifications. These standards often include requirements for the chemical composition, mechanical properties, and heat treatment of the alloy steel. The chemical composition of the alloy steel billets is crucial, as it determines the material's strength, hardness, and resistance to corrosion and high temperatures. The specific composition may vary depending on the intended use, but common alloying elements include chromium, molybdenum, vanadium, and nickel. Additionally, the carbon content is carefully controlled to achieve the desired strength and toughness. In terms of mechanical properties, alloy steel billets for defense applications generally need to have high strength, toughness, and impact resistance. They should be able to withstand extreme conditions, including high pressure, shock, and vibrations. The billets may undergo specific heat treatments, such as quenching and tempering, to achieve the desired mechanical properties. The dimensional specifications for alloy steel billets used in the defense industry are also crucial. They must meet precise size and shape tolerances, as well as surface finish requirements, to ensure compatibility with the manufacturing processes and final products. Furthermore, the billets may need to be certified to specific industry or military standards, such as MIL-STD or ASTM specifications, to ensure their suitability and reliability for defense applications. These standards define the testing methods, quality control requirements, and performance criteria that the alloy steel billets must meet. Overall, the specifications for alloy steel billets used in the defense industry encompass a range of factors, including chemical composition, mechanical properties, dimensional tolerances, and adherence to industry or military standards. These specifications are essential to ensure the performance, durability, and safety of the final defense products.

- Q: How are steel billets rolled into rails?

- The process of hot rolling is employed to transform steel billets into rails. This involves a sequence of steps. To begin, the steel billets are subjected to intense heat in a furnace, raising their temperature to approximately 1200°C. This elevated temperature renders the steel more pliable and easier to mold. Once the billets reach the desired temperature, they are transferred to a rolling mill. Within the rolling mill, the heated steel billets are guided through a succession of rolling stands. These stands consist of pairs of sizeable rolls that gradually diminish the thickness and alter the shape of the billets. As the billets pass through each stand, the rolls apply significant pressure, causing the steel to elongate and adopt the characteristics of a rail. As the billets progress through the rolling mill, they gradually assume the dimensions of rails. The rolling process also confers strength and durability upon the rails, making them suitable for a range of applications, such as railway tracks. During the rolling process, it is common to employ water or oil to cool the rolls and prevent overheating. This cooling also aids in maintaining the desired temperature of the steel billets as they traverse the rolling mill. Once the steel billets have been transformed into rails, they are cut to the desired lengths and undergo further processing, such as straightening and heat treatment, to ensure they meet the required specifications. In conclusion, the hot rolling process is utilized to convert steel billets into rails. This entails heating the billets, guiding them through a series of rolling stands, and gradually shaping them into rails with the desired dimensions. The resulting rails are then subjected to additional processing to prepare them for various applications.

- Q: How do steel billets contribute to the overall safety of a product?

- Steel billets contribute to the overall safety of a product in several ways. Firstly, steel billets are manufactured using a controlled process that ensures a high level of quality and consistency in the material. This means that the steel produced from these billets will have consistent mechanical properties, such as strength and toughness, which are crucial for ensuring the safety of the final product. Additionally, steel billets undergo various testing and inspections during the manufacturing process to ensure that they meet the required specifications and standards. This includes checks for surface defects, internal soundness, and proper chemical composition. By ensuring that the steel billets are defect-free and meet the necessary quality standards, the risk of failure or malfunction in the final product is significantly reduced. Furthermore, steel billets are known for their exceptional strength and durability. Steel is a highly robust material that can withstand high temperatures, pressure, and impacts without deforming or breaking. This inherent strength makes steel billets particularly suitable for applications where safety is a priority, such as in the construction of buildings, bridges, and infrastructure. Moreover, steel billets can be easily shaped and formed into various components and structures, allowing for precise manufacturing and design. This versatility enables engineers and designers to create products with optimal safety features, such as reinforced beams or structures that can withstand extreme loads or impacts. The ability to customize steel billets to meet specific safety requirements ensures that the final product is tailored to address potential safety risks and hazards. Lastly, steel billets are highly resistant to corrosion, making them ideal for applications in harsh environments or exposure to corrosive substances. The resistance to corrosion ensures that the structural integrity of the product is maintained over time, reducing the likelihood of failures due to material degradation. In conclusion, steel billets contribute to the overall safety of a product by providing a high-quality, defect-free, strong, and durable material that can be customized to meet specific safety requirements. The controlled manufacturing process, rigorous testing, and inherent properties of steel make it an ideal choice for ensuring the safety and reliability of various products.

Send your message to us

Continuous Casting Steel Billet Q275/235

- Loading Port:

- Tianjin

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 1000 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords