Damascus Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Damascus Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

Specification

Steel billet(ingot) by cogging or breakdown of semi-finished products, is the raw material of all kinds of steel mill. Billet section of square, round, flat, rectangular and abnormity of several kinds of, mainly related to the shape of rolled products.

CNBM Q235,Q275,Q345,3SP,5SP,20MnSi Billets Steel in Hot Sale

Hot Rolled Steel Billets/ Mild Steel Bar/ Billet Steel Damascus Steel Billet

Specification (see below)

Standard: GB/JIS/ASTM

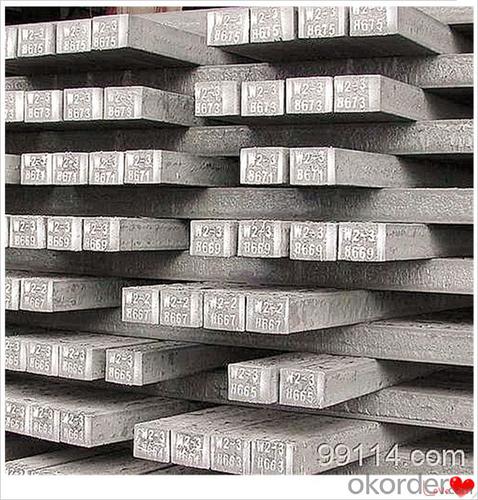

Size: 50*50mm-180*180mm

Length: 3-12mtrs or Customised

Steel material: Q235,Q255,Q275,Q345,3SP,5SP,20MnSi

Technique: Hot rolled

FOB Unit Ton Price $250-350 and Usually I will quote you CFR price.

MOQ: Usually 1000-10000MT/size

Shipment:By Container,Bulk Vessel

Packaging Details: bundles with steel strips or as customers's requirements

Delivery time: Usually within 30 days after the deposit/LC

Inspection:Third party inspection before loading.

Technical data

Feature Steel Billet

Rectangular billet continuous casting billet and mainly general carbon steel, low carbon low silicon cold-rolled material, high quality carbon structural steel, high strength low alloy steel, special steel, etc.

The billet is mainly divided into two kinds from the shape:

Slab: cross section width and height of the ratio of the larger, mainly used for rolling plate.

Billet: equal cross section width and height, or a huge difference, mainly used for rolling steel, wire rod. ,

Steel billets have distinct characteristics as compared with already furnished steel bars and products. Billets have a specific grain structure, which enables the metal to be processed more intricately. Steel billets are also known for their malleability and ductility, especially when exposed to varying temperatures during shaping and molding.

Packaging & Shipping

1. Packaging:

1) Small size: in bundles

2)Big size: in bulk

3)in plastic packing or as per customer requirement

2. Delivery time:

1) Normal size: within 7days send from warehouse directly

2) Special size: with 25-30days customer made for you

3. Trade terms:FOB/CFR/CIF

4. Shippment:

1) length:≤5.8m loaded in 20FT Container with 25-27tons

2) length:≤11.8m loaded in 40FT Container with 25-27tons

3) lengnth:≥12m shipped by bulk vessel, FILO terms

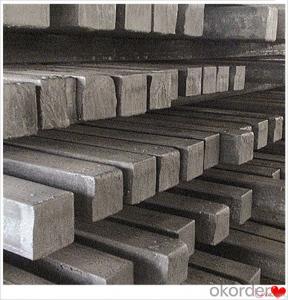

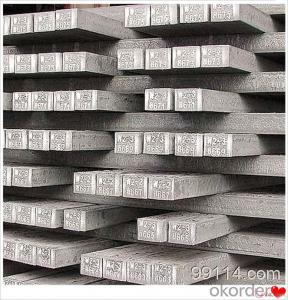

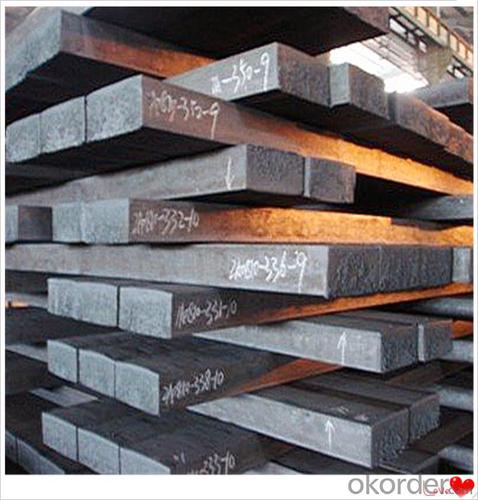

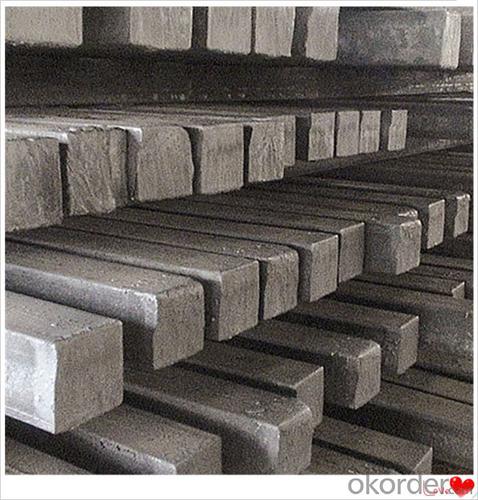

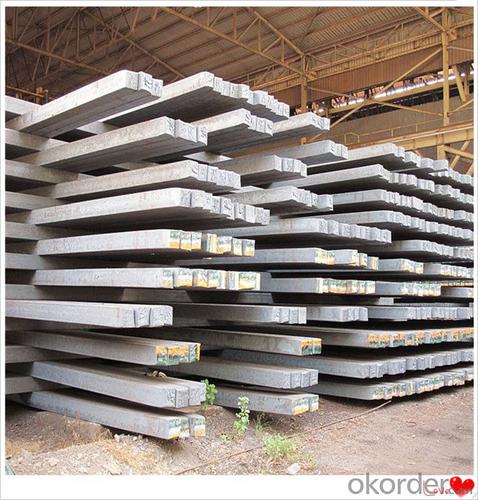

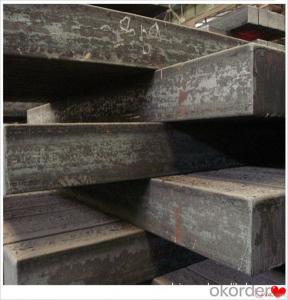

Steel Billet Images

Processing

Usage-Billet Steel

Used for the plant, the bridge,shipment building high-rise building construction,lifting and transportation machinery, equipment manufracturing base building the support foundation pile manufacturing.

Billets, or ingots (as they sometimes referred to), are not of practical use until they have been formed into more functional shapes and sizes. While they have already been put in the furnace, they still require a series of shaping and molding procedures such as hot and cold working, milling and cutting before they are sold in hardware stores, or used for different applications. The unformed billets, however, can be used in striking currency such as coins and as reserves, similar to gold bars.

FAQ-Billet Steel

We have organized several common questions for our clients,may help you sincerely:

1) How about your company?

A world class manufacturer & supplier of castings forging in carbon steel and alloy steel,is one of the large-scale professional investment casting production bases in China,consisting of both casting foundry forging and machining factory. Annually more than 8000 tons Precision casting and forging parts are exported to markets in Europe,America and Japan. OEM casting and forging service available according to customer’s requirements.

2) How to guarantee the quality of the products?

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

3) How long can we receive the product after purchase?

In the purchase of product within three working days, We will arrange the factory delivery as soon as possible. The pecific time of receiving is related to the state and position of customers.Commonly 7 to 10 working days can be served.

4)Do you have your own QC department?

Yes, we have, our QC department will inspect the goods during the process of mass production and after completion of production.

hot sale!!! Cast Steel Grades/ mild steel bar/ billet steel

(1): High quality steel with reasonable price.

(2): Wide excellent experiences with after-sale service.

(3): Every process will be checked by responsible QC which insures every product's quality.

(4): Professional packing teams which keep every packing safely.

(5): Trial order can be done in one week.

(6): Samples can be provided as your requirements.

- Q: What are the main factors affecting the tensile strength of steel billets?

- There are several main factors that affect the tensile strength of steel billets. Firstly, the composition of the steel plays a significant role. The presence of certain elements, such as carbon, manganese, and silicon, can greatly influence the strength of the steel. Carbon, in particular, is a key element in increasing the strength of steel through its ability to form strong interatomic bonds. Secondly, the heat treatment process employed during the production of steel billets is crucial. Heat treatment, such as quenching and tempering, can significantly enhance the tensile strength of the steel by manipulating its microstructure. Quenching involves rapidly cooling the steel, which creates a hardened structure, while tempering involves reheating the steel to a specific temperature to achieve the desired balance of hardness and toughness. Additionally, the grain size of the steel also affects its tensile strength. Fine-grained steel generally exhibits higher strength due to the increased number of grain boundaries, which act as barriers to dislocation movement. On the other hand, coarse-grained steel tends to have lower strength as it allows for easier dislocation movement. Moreover, the presence of impurities or defects in the steel can weaken its tensile strength. Inclusions, such as sulfur, phosphorus, and non-metallic inclusions, can act as stress concentration points and promote crack initiation, leading to reduced strength. Similarly, the presence of voids, porosity, or other structural defects can compromise the overall strength of the steel billets. Lastly, the processing conditions during the manufacturing of steel billets can affect their tensile strength. Parameters such as rolling and forging temperatures, deformation rate, and cooling rate can influence the resulting microstructure and, consequently, the strength of the steel. In conclusion, the main factors affecting the tensile strength of steel billets include the steel composition, heat treatment process, grain size, impurities or defects, and processing conditions. Understanding and optimizing these factors are crucial for producing steel billets with the desired mechanical properties.

- Q: What are the different types of surface treatment methods used for steel billets?

- Steel billets can undergo various surface treatment methods to serve specific purposes. Here are some commonly employed techniques: 1. Pickling: By immersing steel billets in an acidic solution, typically hydrochloric or sulfuric acid, any scale or oxide layers on the surface can be eliminated. Pickling enhances the surface finish and readies the steel for further processing. 2. Shot Blasting: This method involves propelling high-velocity small metal or ceramic particles onto the steel billet surface. The process effectively removes rust, scale, and contaminants, resulting in a clean and smooth finish. 3. Grinding: To eradicate imperfections from the steel billet surface, mechanical abrasive wheels are utilized. Grinding can achieve a specific surface roughness, making it ideal for precision and accuracy requirements. 4. Acid Etching: By applying an acid solution to the steel billet surface, a controlled roughness or texture can be created. This enhances subsequent coating or paint adhesion. 5. Galvanizing: A layer of zinc is applied to the steel billets in this popular method. Zinc acts as a sacrificial barrier, providing excellent corrosion resistance and protecting the underlying steel from oxidation. 6. Powder Coating: Electrostatically applying a dry powder to the steel billet surface characterizes this technique. Upon heating, the powder melts and forms a protective layer known for its durability, corrosion resistance, and ability to offer diverse decorative finishes. 7. Passivation: This chemical process aims to enhance the corrosion resistance of stainless steel billets. It involves eliminating iron contaminants and forming a passive oxide layer that safeguards the steel from oxidation. These examples represent only a fraction of the surface treatment methods available for steel billets. The selection of a method depends on factors like desired surface finish, intended steel application, and required level of corrosion resistance.

- Q: How do steel billets contribute to the telecommunications industry?

- Steel billets are used in the telecommunications industry to manufacture various infrastructure components such as towers, poles, and cables. These components provide the necessary support and stability for the installation of telecommunication equipment, ensuring reliable and efficient communication networks. Steel billets contribute to the industry by providing the raw material needed for the production of these essential infrastructure components.

- Q: What are the causes of internal cracks in continuous casting billet?

- A French Research Institute of carbon, sulfur and phosphorus influence on continuous casting billet hot cracking, a total of three test groups of carbon manganese steel, carbon, sulfur and phosphorus content of each sample is different.

- Q: How do steel billets contribute to the construction of bridges and infrastructure?

- Steel billets are essential to the construction of bridges and infrastructure as they serve as the raw material for manufacturing various structural components. These billets, which are heated and then shaped into desired forms, provide the necessary strength and durability required to withstand heavy loads and harsh environmental conditions. They are frequently used to fabricate beams, columns, and other critical elements that make up the skeletal framework of bridges and infrastructure projects. Additionally, steel billets can be further processed to produce reinforcing bars, which enhance the structural integrity of concrete structures, such as foundations and roadways. Overall, steel billets play a vital role in ensuring the structural stability and longevity of bridges and infrastructure, making them indispensable in the construction industry.

- Q: Can steel billets be polished for improved surface finish?

- No, steel billets cannot be polished for improved surface finish as they are usually unfinished or have a rough surface due to the manufacturing process.

- Q: How are steel billets used in the production of gear blanks?

- Gear blanks are made from steel billets, which are essential for their production. Steel billets are long bars of steel that possess the necessary characteristics for gear manufacturing. These billets are made from high-quality steel and provide the material needed for creating gear blanks. To shape the gear blanks, the steel billets are heated to a specific temperature, making them easier to work with. Various forming processes, such as forging or extrusion, are then used to transform the billets into the desired shape of the gear blank. Once the gear blank is formed, it undergoes further machining processes to refine its shape, dimensions, and surface finish. This includes turning, milling, drilling, or grinding operations. Precise machining is necessary to meet the required specifications for the final gear product. The gear blanks produced from steel billets are the foundation for creating different types of gears, including spur gears, helical gears, bevel gears, or worm gears. These gear blanks undergo additional steps, such as heat treatment and surface hardening, to enhance their mechanical properties and increase their resistance to wear and fatigue. In conclusion, steel billets are crucial in the production of gear blanks as they provide the raw material for creating gears. Through heating, forming, and machining processes, the steel billets are transformed into gear blanks, which are then further processed to create the final gears used in various applications.

- Q: What are the main surface finishes available for steel billets?

- The main surface finishes available for steel billets include mill finish, pickled and oiled (P&O), galvanized, painted, and coated finishes. Mill finish refers to the surface of the steel billet as it comes from the rolling mill, which is typically characterized by a rough and unfinished appearance. This finish is suitable for applications where aesthetics are not a priority, such as when the billets will be further processed or coated. Pickled and oiled (P&O) finish involves treating the steel billets with an acid solution to remove any mill scale or impurities, followed by applying a thin layer of oil to protect the surface from oxidation. This finish provides a clean and smooth surface, making it suitable for applications where a high-quality appearance is desired. Galvanized finish involves immersing the steel billets in a zinc bath to create a protective layer of zinc coating over the surface. This finish provides excellent corrosion resistance, making it ideal for outdoor applications or environments with high moisture or chemical exposure. Painted finish involves applying a layer of paint onto the surface of the steel billets. This finish offers both aesthetic appeal and protection against corrosion, as the paint acts as a barrier between the steel and the external environment. Painted finishes can be customized in terms of color and texture to suit specific requirements. Coated finishes involve applying a specialized coating onto the surface of the steel billets. These coatings can include epoxy, polyurethane, or other protective materials that provide enhanced corrosion resistance, chemical resistance, or heat resistance. Coated finishes are often used in industries such as automotive, construction, or oil and gas, where the billets are subjected to harsh conditions. Overall, the choice of surface finish for steel billets depends on the specific application requirements, including aesthetics, corrosion resistance, durability, and environmental factors.

- Q: What are the different types of mechanical property testing methods for steel billets?

- There are several different types of mechanical property testing methods used to evaluate the quality and strength of steel billets. These methods include: 1. Tensile Testing: Tensile testing is one of the most commonly used methods to determine the mechanical properties of steel billets. It involves applying a tensile force to a small sample of the billet until it fractures. This test measures the strength, yield strength, elongation, and reduction in area of the material. 2. Impact Testing: Impact testing is used to assess the toughness and resistance to fracture of steel billets. It involves striking a notched specimen with a pendulum or hammer and measuring the energy absorbed during fracture. The results provide information about the material's ability to withstand sudden shocks or dynamic loads. 3. Hardness Testing: Hardness testing determines the resistance of the steel billet to indentation or scratching. Various methods can be employed, such as Rockwell, Brinell, or Vickers hardness testing. The results are often correlated with other mechanical properties, such as strength and ductility. 4. Charpy Testing: Charpy testing is a type of impact test specifically designed to evaluate the notch toughness of steel billets. It involves striking a notched specimen with a pendulum, and the energy absorbed during fracture is measured. This test is particularly useful in assessing the material's behavior under low-temperature conditions. 5. Bend Testing: Bend testing is performed to assess the ductility and flexibility of steel billets. It involves bending a sample around a specified radius until it fractures or shows signs of cracking. This test provides information about the material's ability to withstand deformation without breaking. 6. Fatigue Testing: Fatigue testing is used to evaluate the steel billet's resistance to cyclic loading or repeated stress. It involves subjecting a sample to a varying load, and the number of cycles required for failure is recorded. This test helps determine the material's durability and its ability to withstand long-term stress. These mechanical property testing methods play a crucial role in ensuring the quality and reliability of steel billets for various applications. By evaluating the strength, toughness, hardness, and other mechanical properties, manufacturers and engineers can make informed decisions about the suitability of the material for specific uses.

- Q: What is the purpose of steel billets?

- Steel billets have a vital role in the steel manufacturing industry, as they act as the primary material for producing a range of steel products. These billets are semi-finished goods that usually have a square or rectangular shape, and they are created through the casting or hot rolling process. Once formed, these billets undergo further processing, including forging, rolling, or extrusion, to manufacture finished steel products such as bars, rods, wire, pipes, and tubes. The significance of steel billets lies in their ability to provide a consistent and uniform starting material that can be easily molded and shaped into various products. With desirable qualities like strength, durability, and ductility, these billets are well-suited for applications in construction, automotive, infrastructure, machinery, and many other industries. By utilizing steel billets, manufacturers can efficiently produce steel products with precise dimensions, mechanical properties, and surface finishes. By controlling the composition and processing techniques of the billets, steel manufacturers can customize the final product to meet specific customer requirements, ensuring optimal performance and quality. In conclusion, steel billets serve as the foundation for manufacturing various steel products. They play a crucial role in shaping and forming steel into the desired finished products, enabling industries to effectively meet the diverse needs of modern society.

Send your message to us

Damascus Steel Billet Q235,Q255,Q275,Q345,3SP,5SP,20MnSi Made in China

- Loading Port:

- China main port

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 20 m.t.

- Supply Capability:

- 200000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords