Steel Beam Sizes

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Specifications of Steel Beam Sizes

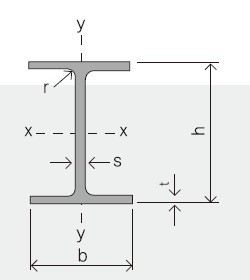

1. Product name: Steel Beam

2. Standard: EN10025, GB Standard, ASTM, JIS etc.

3. Grade: Q235B, A36, S235JR, Q345, SS400 or other equivalent.

4. Length: 5.8M, 6M, 9M, 10M, 12M or as your requirements

Steel Beam Sizes

|

Section |

Standard Sectional Dimensions(mm) | ||||

|

|

h |

b |

s |

t |

Mass Kg/m |

|

IPE80 |

80 |

46 |

3.80 |

5.20 |

6.00 |

|

IPE100 |

100 |

55 |

4.10 |

5.70 |

8.10 |

|

IPE120 |

120 |

64 |

4.80 |

6.30 |

10.40 |

|

IPE140 |

140 |

73 |

4.70 |

6.90 |

12.90 |

|

IPE160 |

160 |

82 |

5.00 |

7.40 |

15.80 |

|

IPE180 |

180 |

91 |

5.30 |

8.00 |

18.80 |

|

IPE200 |

200 |

100 |

5.60 |

8.50 |

22.40 |

|

IPE220 |

220 |

110 |

5.90 |

9.20 |

26.20 |

|

IPE240 |

240 |

120 |

6.20 |

9.80 |

30.70 |

|

IPE270 |

270 |

135 |

6.60 |

10.20 |

36.10 |

|

IPEAA80 |

80 |

46 |

3.20 |

4.20 |

4.95 |

|

IPEAA100 |

100 |

55 |

3.60 |

4.50 |

6.72 |

|

IPEAA120 |

120 |

64 |

3.80 |

4.80 |

8.36 |

|

IPEAA140 |

140 |

73 |

3.80 |

5.20 |

10.05 |

|

IPEAA160 |

160 |

82 |

4.00 |

5.60 |

12.31 |

|

IPEAA180 |

180 |

91 |

4.30 |

6.50 |

15.40 |

|

IPEAA200 |

200 |

100 |

4.50 |

6.70 |

17.95 |

Applications of Steel Beam Sizes

Steel Beams are widely used used in various building structures and engineering structures such as roof beams, bridges, transmission towers, hoisting machinery and transport machinery, ships, industrial furnaces, reaction tower, container frame and warehouse etc.

Packing & Delivery Terms of Steel Beam Sizes

1. Package: All the IPE/IPEAA Beam Steel will be tired by wire rod in bundles

2. Bundle weight: not more than 3.5MT for bulk vessel; less than 3 MT for container load

3. Marks:

Color marking: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: there will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

4. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

5. Shipment: In containers or in bulk cargo

6. Delivery time: All the IPE/IPEAA Beam Steel will be at the port of the shipment within 45 days after receiving the L/C at sight ot the advance pyment.

7. Payment: L/C at sight; 30% advance payment before production, 70% before shipment by T/T, etc.

Production flow of Steel Beam Sizes

Material prepare (billet) —heat up—rough rolling—precision rolling—cooling—packing—storage and transportation

- Q: Can steel I-beams be used for mezzanines?

- Indeed, mezzanines can utilize steel I-beams. In the realm of construction, steel I-beams are widely employed due to their robustness and endurance. They furnish exceptional structural reinforcement and possess the capacity to endure substantial burdens. Given that mezzanines function as intermediate floors between primary floors, it is crucial to secure them with a reliable and solid support system to guarantee safety and stability. Steel I-beams are the perfect solution for this application as they furnish the requisite strength and rigidity to sustain the added weight of the mezzanine structure, which encompasses individuals, furnishings, and equipment. Furthermore, steel I-beams can be effortlessly tailored and crafted to meet specific design prerequisites, rendering them a sought-after choice for erecting mezzanines in industrial, commercial, and residential edifices.

- Q: Can steel I-beams be used in seismic retrofitting or strengthening projects?

- Yes, steel I-beams can be used in seismic retrofitting or strengthening projects. Steel I-beams are often preferred in seismic retrofitting due to their high strength and ductility. They can be used to reinforce existing structures by adding additional support and stiffness to the building. Steel I-beams are commonly used to strengthen walls, columns, and floors, which helps to improve the building's ability to withstand seismic forces. Additionally, steel I-beams can be installed in a variety of configurations, such as adding them as braces or installing them as a moment frame system, depending on the specific needs of the retrofitting project. Overall, steel I-beams are a versatile and effective solution for seismic retrofitting and strengthening projects.

- Q: Can steel I-beams be used to create mezzanine floors?

- Yes, steel I-beams can be used to create mezzanine floors. Mezzanine floors are intermediate floors that are constructed between the main floors of a building, typically creating additional usable space. Steel I-beams are commonly used in the construction industry due to their strength, durability, and ability to support heavy loads. They are ideal for creating mezzanine floors as they can provide the necessary structural support to accommodate the additional weight and ensure the safety of the structure. Additionally, steel I-beams can be customized to fit the specific dimensions and requirements of the mezzanine floor, making them a versatile and efficient choice for this application.

- Q: What are the factors to consider when calculating load capacity for steel I-beams?

- When calculating the load capacity for steel I-beams, there are several factors that need to be considered. These factors include the material properties of the steel, the dimensions and shape of the beam, the support conditions, and the applied loads. 1. Material properties: The type and grade of steel used for the I-beam will determine its strength and stiffness. Different steel alloys have varying tensile and yield strengths, which directly affect the load capacity. It is crucial to know the properties of the steel to accurately calculate the load capacity. 2. Beam dimensions: The dimensions of the I-beam, such as its depth, width, and thickness, play a significant role in determining its load capacity. A larger and thicker beam will generally have a higher load-carrying capacity. The beam's cross-sectional shape also needs to be considered, as it affects the beam's moment of inertia and its resistance against bending. 3. Support conditions: The way the I-beam is supported at its ends or along its span greatly influences its load capacity. The beam can be supported in various ways, such as simply supported, fixed at both ends, or continuous over multiple supports. The support conditions determine the maximum bending moment and shear forces the beam can withstand. 4. Applied loads: The loads exerted on the I-beam, including dead loads, live loads, and other dynamic loads, need to be accurately determined. Dead loads refer to the weight of the structure itself and any permanent fixtures, while live loads represent temporary or variable loads like people, furniture, or equipment. The magnitude, distribution, and duration of these loads must be considered to calculate the load capacity accurately. 5. Deflection criteria: Depending on the intended use of the I-beam, deflection criteria may also need to be considered. If the beam is expected to support sensitive equipment, excessive deflection could cause operational issues. The acceptable deflection limits must be taken into account while calculating the load capacity. Considering these factors is crucial when calculating the load capacity for steel I-beams. It is essential to consult relevant design codes and standards, such as the American Institute of Steel Construction (AISC) Manual, to ensure accurate calculations and safe structural design.

- Q: What are the standard lengths of steel I-beams?

- The specific industry and application dictate the varying standard lengths of steel I-beams. In construction and engineering, the typical lengths for these beams range from 20 to 60 feet, making them the most frequently utilized. These lengths adhere to the demands of building codes and guarantee adequate support and structural integrity for a diverse array of construction endeavors. It is worth mentioning that tailored lengths can be produced to fulfill particular project requirements, albeit at an extra expense and potentially necessitating a special order.

- Q: How can I distinguish I-beam from H?

- The I-beam section is well pressed and resistant to pulling, but the section size is too narrow to resist torsion. H steel is vice versa, so both have advantages and disadvantages.

- Q: Can steel I-beams be used in bridge or overpass construction?

- Yes, steel I-beams can be used in bridge or overpass construction. Steel I-beams are commonly used in the construction of bridges and overpasses due to their strength, durability, and versatility. They are ideal for supporting heavy loads and providing structural stability, making them a popular choice for many civil engineering projects. Steel I-beams can be designed and fabricated to meet specific project requirements, allowing for customization and optimization of the bridge or overpass design. Additionally, steel I-beams are resistant to corrosion and can withstand harsh weather conditions, making them suitable for long-term use in outdoor structures. Overall, steel I-beams are a reliable and effective choice for bridge and overpass construction.

- Q: Can steel I-beams be used in water or wastewater treatment plant renovation projects?

- Steel I-beams are a suitable option for water or wastewater treatment plant renovation projects. Their strength, durability, and versatility make them commonly used in construction projects. In the case of water or wastewater treatment plant renovations, where there is a need for heavy loads and high structural requirements, steel I-beams are an ideal choice. They can be utilized for various purposes, including supporting large tanks, bridges, walkways, and platforms. Moreover, steel I-beams exhibit excellent resistance to corrosion, which is crucial in water or wastewater treatment plants where exposure to corrosive elements is common. Overall, steel I-beams provide a reliable and cost-effective solution for water or wastewater treatment plant renovation projects.

- Q: Can steel I-beams be used for mezzanine storage systems?

- Yes, steel I-beams can be used for mezzanine storage systems. They are commonly used in constructing mezzanines due to their strength, durability, and load-bearing capacity. Steel I-beams provide the necessary support and stability required for safely storing heavy loads on mezzanine floors.

- Q: What are the load-bearing capacity of rectangular and I-beam steel sections of the same size?

- You check the steel form to see a Wx value in it, which represents the most important load condition.There are two general force formulas:F/A: force / areaM/Wx: bending moment / flexural modulusThere are other instability calculations.

1. Manufacturer Overview

| Location | Qinhuangdao, China |

| Year Established | 2000 |

| Annual Output Value | Above US$ 300 Million |

| Main Markets | Mid East; Africa; Southeast Asia; Brazil |

| Company Certifications | ISO 9001:2008; |

2. Manufacturer Certificates

| a) Certification Name | |

| Range | |

| Reference | |

| Validity Period |

3. Manufacturer Capability

| a) Trade Capacity | |

| Nearest Port | Tianjin; |

| Export Percentage | 70% - 80% |

| No.of Employees in Trade Department | 21-50 People |

| Language Spoken: | English; Chinese; |

| b) Factory Information | |

| Factory Size: | Above 400,000 square meters |

| No. of Production Lines | 2 |

| Contract Manufacturing | OEM Service Offered; |

| Product Price Range | Average |

Send your message to us

Steel Beam Sizes

- Loading Port:

- Tianjin Port

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25MT m.t.

- Supply Capability:

- 10000MT m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords