Steel I Beam IPE in Chinese Standard and European Standard for Asia and Africa

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of Steel I Beam IPE Description:

Steel I beam IPE is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". Steel I beam IPE is usually made of structural steel and is used in construction and civil engineering. The Steel I beam IPE resists shear forces, while the flanges resist most of the bending moment experienced by the beam. Steel I beam IPE theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of Steel I Beam IPE:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. Steel I Beam IPE Images:

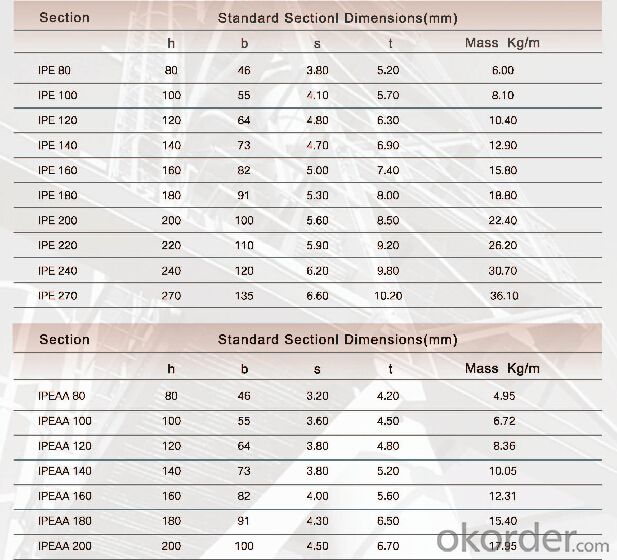

4. Steel I Beam IPE Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

We have established the international advanced quality management system,every link from raw material to final product we have strict quality test;We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: What are the different types of connections used for Steel I-Beams in bridge construction?

- There are several types of connections used for Steel I-Beams in bridge construction, including bolted connections, welded connections, and riveted connections. Each type of connection has its advantages and disadvantages, and the choice depends on factors such as load capacity, cost, and ease of construction. Bolted connections are commonly used due to their flexibility and ease of installation, while welded connections offer a higher load capacity but require skilled labor and may be more expensive. Riveted connections, although less common nowadays, were widely used in the past and offer good load capacity and structural integrity. Ultimately, the choice of connection type depends on the specific requirements and design considerations of the bridge project.

- Q: How do steel I-beams perform in terms of sound insulation?

- Steel I-beams do not perform well in terms of sound insulation. This is because steel is a dense and rigid material that easily transmits sound vibrations. As a result, steel I-beams can act as conduits for sound, allowing it to travel through the structure and making it difficult to achieve effective sound insulation. To improve sound insulation in buildings with steel I-beams, additional measures such as adding insulation materials, using acoustic panels, or implementing soundproofing techniques may be necessary.

- Q: How do steel I-beams compare to timber beams in terms of strength and durability?

- When it comes to comparing steel I-beams and timber beams, it is evident that steel I-beams have remarkable strength and durability. Timber beams have been used for centuries and have their own advantages, such as their natural appearance and easy installation. However, steel I-beams offer superior strength and longevity. In terms of strength, steel I-beams have a much higher load-carrying capacity than timber beams. Steel is inherently stronger than wood, enabling I-beams to support heavier loads without bending or breaking. This makes steel I-beams the preferred choice for large-scale construction projects like high-rise buildings, bridges, and industrial structures. Durability is another area where steel I-beams excel over timber beams. Steel is resistant to rot, decay, pests, and moisture, which are common challenges faced by timber beams. Steel I-beams have a longer lifespan and require minimal maintenance compared to timber, which may need regular inspections, treatments, and repairs to maintain structural integrity. Furthermore, steel I-beams offer greater fire resistance than timber beams. Steel does not burn or contribute to the spread of fire, making it a safer option in terms of structural stability and protecting occupants in the event of a fire. Despite these advantages, there are situations where timber beams may be preferred. Timber beams are commonly used in residential construction or smaller-scale projects where aesthetics and cost are important considerations. Timber beams can provide a more natural, warm, and appealing look, which may be desirable in specific architectural styles. In conclusion, steel I-beams exceed timber beams in terms of strength, durability, and fire resistance. They are the preferred choice for heavy load-bearing structures and projects where longevity and minimal maintenance are crucial factors. However, timber beams still have their place in smaller-scale construction projects, where aesthetics and cost take precedence over sheer strength and durability.

- Q: What are the different types of steel I-beam connections for beam-to-column joints?

- Beam-to-column joints can be made using various types of steel I-beam connections. Some commonly used options include: 1. Welded connections: This is the traditional and widely used method where the beam is welded directly to the column using fillet or groove welds. Welded connections offer high strength and rigidity but require skilled labor for proper execution. 2. Bolted connections: These connections involve using high-strength bolts and nuts to connect the beam and column. They are easy to assemble and disassemble, making them suitable for applications requiring flexibility or modifications. Bolted connections also provide good strength and rigidity. 3. Riveted connections: Although less popular nowadays due to more efficient methods, riveted connections were commonly used in the past. They involve using rivets to connect the beam and column. Riveted connections offer high strength and rigidity but require skilled labor and time-consuming installation. 4. Pinned connections: Pinned connections utilize a pin or bolt to connect the beam and column. This allows for rotational movement at the joint, which is beneficial in structures subjected to dynamic loads or thermal expansion. Pinned connections provide moderate strength and rigidity. 5. Moment connections: These connections are designed to transfer axial forces and bending moments between the beam and column. They offer high strength and rigidity and are commonly used in structures requiring the transfer of large loads or moments. Moment connections can be achieved through welding, bolted plates, or specialized connection details. 6. Shear connections: Primarily used in structures with shear loading, shear connections transfer shear forces between the beam and column. They can be achieved through welded plates, bolted plates, or specialized connection details. It is crucial to select the appropriate type of connection based on the specific requirements of the structure, including loadings, design criteria, and construction methods. Consulting a structural engineer or following recognized design codes and standards is essential to ensure proper selection and design of steel I-beam connections for beam-to-column joints.

- Q: What are the different methods of transporting steel I-beams to construction sites?

- There are several methods of transporting steel I-beams to construction sites, depending on factors such as the size and weight of the beams, as well as the accessibility of the construction site. Here are some of the different methods commonly used: 1. Flatbed trucks: This is the most common method of transportation for steel I-beams. Flatbed trucks are equipped with a large flat platform, allowing for easy loading and unloading of the beams. They can transport a wide range of sizes and weights of I-beams, making them a versatile option. 2. Crane trucks: For larger and heavier I-beams, crane trucks are often used. These trucks have a hydraulic crane mounted on the back, which can lift and move the beams onto the construction site. Crane trucks are especially useful when the construction site has limited access or requires precise placement of the beams. 3. Rail transportation: In some cases, when the distance between the steel mill and the construction site is significant, rail transportation may be used. Specialized railcars designed for carrying large and heavy loads, such as flatcars or gondolas, are utilized to transport the steel I-beams. This method is efficient for long-distance transportation, especially for large quantities of beams. 4. Barge transportation: When construction sites are located near bodies of water, such as rivers or coastal areas, barge transportation can be a viable option. Barges are large flat-bottomed boats that can carry heavy loads. Steel I-beams can be loaded onto the barge, and then transported to the construction site by water, providing an efficient and cost-effective method for large-scale projects. 5. Air transportation: In exceptional cases, when time is of the essence or when access to the construction site is extremely challenging, air transportation may be considered. Helicopters or cargo planes can be utilized to lift and transport the steel I-beams directly to the construction site. However, due to the high costs involved, this method is typically used for urgent or remote projects. It is important to consider the size, weight, and accessibility of the construction site when determining the most suitable method of transportation for steel I-beams. Each method has its advantages and limitations, and the choice will depend on the specific requirements and constraints of the project.

- Q: What angles, angles and channels are used in general? Please try to be specific

- Profiles are commonly used in construction for steel structures, plant buildings (single deck, multiple), adding (inserting) layers, and simple and independent components: Roofing frames, interior and exterior steel staircases, etc.In steel construction plants (buildings), what you call those profiles are useful

- Q: Can steel I-beams be customized to specific project requirements?

- Indeed, it is possible to customize steel I-beams according to specific project requirements. These steel I-beams possess exceptional adaptability and can be tailored to adhere to unique specifications. The process of customization entails modifying the dimensions, lengths, and shapes of the beams to suit the project's distinct load-bearing prerequisites. This may involve adjusting the height, width, and thickness of the flanges and web of the beam. Furthermore, steel I-beams can be personalized through the application of various surface treatments, such as galvanization or painting, to enhance their durability and resistance to corrosion. Ultimately, the capacity to customize steel I-beams facilitates the attainment of an optimal structural design and guarantees the precise fulfillment of the project's demands.

- Q: How do steel I-beams contribute to sustainable construction?

- There are multiple ways in which steel I-beams contribute to sustainable construction: 1. Durability: Steel I-beams possess high durability and can withstand extreme weather conditions, earthquakes, and fire. This longevity reduces the need for frequent repairs or replacements, thereby decreasing material waste and resource consumption throughout a building's lifespan. 2. Recyclability: Steel stands as one of the most recyclable materials globally. At the end of their life cycle, steel I-beams can be easily recycled without compromising their structural integrity. This diminishes the demand for new steel production and conserves natural resources, energy, and emissions associated with the extraction and manufacturing of new materials. 3. Energy efficiency: The construction of steel I-beams can occur off-site, under controlled conditions, resulting in accurate sizing and reduced waste during the construction process. The precise dimensions and lightweight properties of steel also optimize the design and construction process, leading to efficient material usage and decreased transportation costs. 4. Versatility: Steel I-beams offer design flexibility, enabling architects and engineers to create open, spacious areas with minimal support columns. This versatility not only enhances the aesthetic appeal of a building but also maximizes the utilization of natural light and ventilation. As a result, the need for artificial lighting and HVAC systems is reduced, minimizing energy consumption and greenhouse gas emissions. 5. Sustainable supply chain: The steel industry has implemented various sustainable practices, such as utilizing recycled content, minimizing water usage, and enhancing energy efficiency in their production processes. By selecting steel I-beams, builders can support these sustainable initiatives and contribute to a more environmentally conscious supply chain. In conclusion, steel I-beams provide durable, recyclable, energy-efficient, and versatile building materials, ultimately contributing to sustainable construction. Their utilization reduces waste, conserves natural resources, and lessens the environmental impact of the construction industry.

- Q: Can steel I-beams be used for manufacturing plants?

- Indeed, manufacturing plants can utilize steel I-beams. These beams are extensively employed in the construction field owing to their remarkable strength-to-weight ratio and adaptability. They offer exceptional structural reinforcement, capable of enduring substantial burdens, which renders them perfect for deployment in manufacturing plants where heavy machinery and equipment are prevalent. Moreover, steel I-beams boast long-lasting sturdiness, as they are impervious to corrosion and capable of withstanding harsh environmental circumstances. Furthermore, their straightforward installation process and potential for customization to meet specific project demands contribute to their widespread popularity in manufacturing plants.

- Q: What are the different methods of joining steel I-beams together?

- There are several methods of joining steel I-beams together, depending on the specific requirements of the structure and the desired strength and durability of the joint. Some common methods include: 1. Welding: Welding is one of the most commonly used methods for joining steel I-beams together. It involves melting and fusing the edges of the beams using heat, creating a strong and permanent bond. Different types of welding techniques, such as arc welding or MIG welding, can be employed depending on the specific application. 2. Bolted connections: Bolted connections involve using high-strength bolts to connect the beams together. Holes are drilled in the flanges and webs of the beams, and bolts are inserted and tightened to create a secure connection. This method allows for easy disassembly and modification of the structure if required. 3. Riveting: Riveting is an older method of joining steel beams, but it can still be used for specific applications. It involves inserting a metal rivet through pre-drilled holes in the beams and then hammering or compressing the rivet to create a permanent connection. Riveted joints are often used in historical or architectural structures for aesthetic purposes. 4. Adhesive bonding: Adhesive bonding involves using high-strength adhesives or epoxy resins to bond the surfaces of the steel beams together. This method is often used in situations where welding or bolting is not possible or desirable. Adhesive bonding can provide a strong and durable joint, but it may not be suitable for high-stress applications. 5. Mechanical fasteners: Mechanical fasteners, such as steel plates or brackets, can be used to join steel I-beams together. These fasteners are typically bolted or welded to the beams, providing additional strength and stability to the joint. Mechanical fasteners are often used in conjunction with other joining methods to enhance the structural integrity of the connection. It is important to consider factors such as the load-bearing capacity, structural integrity, and ease of installation and maintenance when selecting the most appropriate method for joining steel I-beams together. Consulting with a structural engineer or a professional in the field can help determine the best joining method for a specific application.

Send your message to us

Steel I Beam IPE in Chinese Standard and European Standard for Asia and Africa

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords