Waler Beam

Waler Beam Related Searches

Aluma Beam Beam Launcher Lvl Beam Beam Material Simple Beam L Beam Steel Beam 2100 Stainless Steel I Beam Aluminum T Beam Beam Joints Bosch Beam Wiper Blades Joining Steel Beams Simple Beam Bridge Blasting Wire Hot Rolled H Beam Kanye West Ultralight Beam Snl Kanye West Snl Ultralight Beam H Beam Aluminium Ultralight Beam Kanye West Snl Aluminium H Beam Structural Columns And Beams Bolting Steel Beams Together Aluma Beam Capacity Steel Column To Steel Beam ConnectionWaler Beam Supplier & Manufacturer from China

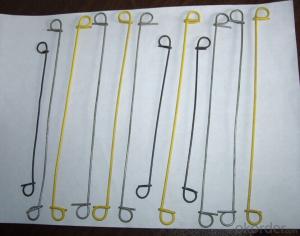

Waler Beam is a type of steel product that is widely used in construction and engineering projects. Known for its strength and durability, it is an essential component in various structures such as bridges, buildings, and other infrastructures. This product is designed to withstand significant weight and pressure, making it a popular choice among architects and engineers.The Waler Beam is utilized in a variety of applications, including support beams in buildings, bridge construction, and as a key component in temporary or permanent structures. Its versatility allows for easy integration into different projects, and it can be customized to meet specific design requirements. This product is also used in various industries, such as mining, agriculture, and transportation, where heavy-duty support structures are needed.

Okorder.com is a leading wholesale supplier of Waler Beam products, offering a vast inventory to cater to the needs of various industries. With their extensive range of products, customers can find the perfect Waler Beam for their specific project requirements. The company's commitment to quality and customer satisfaction ensures that each Waler Beam is manufactured to the highest standards, providing reliable support and long-lasting performance.

Hot Products