I Beam Steel IPEAA Type Used for Mineral Site with Light Weight

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

1. Structure of I Beam Steel IPEAA Description:

I beam steel IPEAA is a beam with an I-shaped cross-section. The horizontal elements of the "I" are known as flanges, while the vertical element is termed the "web". I beam steel IPEAA is usually made of structural steel and is used in construction and civil engineering. The I beam steel IPEAA resists shear forces, while the flanges resist most of the bending moment experienced by the beam. I beam steel IPEAA theory shows that the I-shaped section is a very efficient form for carrying both bending and shears loads in the plane of the web.

2. Main Features of I Beam Steel IPEAA:

• Grade: Q235

• Type: Mild carbon steel

• Deflection: The stiffness of the I-beam will be chosen to minimize deformation

• Vibration: The stiffness and mass are chosen to prevent unacceptable vibrations, particularly in settings sensitive to vibrations, such as offices and libraries.

• Local yield: Caused by concentrated loads, such as at the beam's point of support.

3. I Beam Steel IPEAA Images:

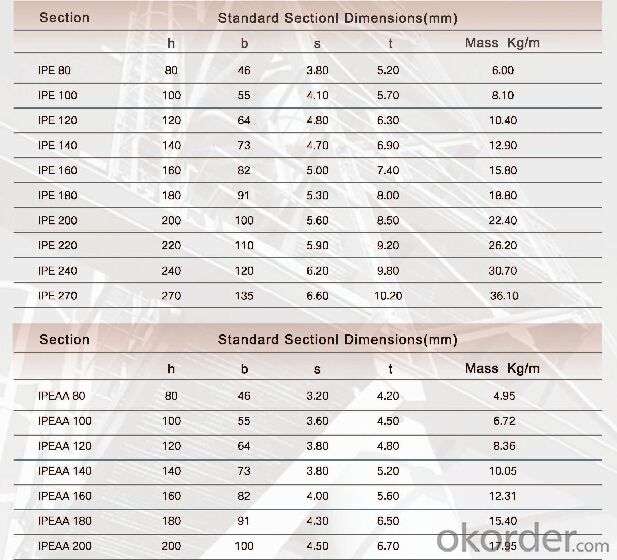

4. I Beam Steel IPEAA Specification:

5. FAQ

We have organized several common questions for our clients,may help you sincerely:

①Is this product same as W beam?

In the United States, the most commonly mentioned I-beam is the wide-flange (W) shape. These beams have flanges in which the planes are nearly parallel. Other I-beams include American Standard (designated S) shapes, in which flange surfaces are not parallel, and H-piles (designated HP), which are typically used as pile foundations. Wide-flange shapes are available in grade ASTM A992,[4] which has generally replaced the older ASTM grades A572 and A36.

②How to inspect the quality?

We have a professional inspection group which belongs to our company. We resolutely put an end to unqualified products flowing into the market. At the same time, we will provide necessary follow-up service assurance.

③Is there any advantage about this kind of product?

Steel I beam bar IPE has a reduced capacity in the transverse direction, and is also inefficient in carrying torsion, for which hollow structural sections are often preferred.

- Q: How do steel I-beams perform in terms of moisture resistance?

- Steel I-beams generally have good moisture resistance. The steel used in their construction is typically treated to prevent corrosion and rusting. However, prolonged exposure to moisture and humidity can still lead to some level of corrosion over time. Therefore, it is important to provide proper protection and maintenance to ensure their long-term performance in moisture-prone environments.

- Q: What are the common loadings and forces that steel I-beams need to withstand?

- Steel I-beams commonly need to withstand various loadings and forces such as dead load (the weight of the beam itself and any permanent fixtures attached to it), live load (the weight of people, furniture, and other temporary loads), wind load, seismic load, and snow load. Additionally, I-beams may also need to resist forces like bending moments, shear forces, and torsion.

- Q: How do steel I-beams perform in areas with high levels of chemical exposure?

- Due to their inherent resistance to corrosion, steel I-beams are well-suited for areas exposed to high levels of chemicals. These I-beams are typically coated with protective layers, such as galvanized coatings or epoxy paint, creating barriers against chemical substances. This effectively prevents the steel from reacting with or being damaged by corrosive elements in the environment. In addition, the structural design of I-beams, with their sturdy shape and cross-sectional properties, enhances their ability to withstand chemical exposure. The I-shaped profile provides exceptional strength and load-bearing capacity, making them ideal for heavy industrial applications, including chemical processing plants, refineries, and wastewater treatment facilities. However, it is important to recognize that not all chemicals have the same impact on steel I-beams. Some highly acidic or alkaline substances, as well as certain solvents or aggressive chemicals, may still cause corrosion or deterioration of the protective coatings over time. Therefore, it is vital to carefully choose the appropriate steel type, protective coatings, and maintenance practices based on the specific chemicals present in the area. This ensures the long-term performance and durability of steel I-beams in such environments. Regular inspections, maintenance, and prompt repair of any coating damages or signs of corrosion are also recommended to prolong the lifespan of the I-beams and maintain their structural integrity.

- Q: Can Steel I-Beams be used for airport hangars?

- Airport hangars can indeed make use of steel I-beams. These beams are widely utilized in the construction of large industrial and commercial structures, including airport hangars. Their ability to bear heavy loads and provide strong structural support makes them an ideal choice for supporting the weight of the hangar's roof and walls. Furthermore, steel I-beams offer durability and fire resistance, ensuring a reliable option for hangar construction. The adaptable nature of steel I-beams also allows for customized hangar designs, accommodating different sizes and configurations to meet the specific requirements of the airport and its aircraft. All in all, steel I-beams are a popular and practical option for building airport hangars due to their strength, durability, and flexibility.

- Q: Are there any special considerations when designing with steel I-beams for long-span structures?

- Yes, there are several special considerations when designing with steel I-beams for long-span structures. Firstly, the deflection and stability of the beams must be carefully analyzed to ensure they can support the loads without sagging or buckling. Additionally, the connection details between the beams and other structural elements need to be meticulously designed to provide adequate strength and ensure proper load transfer. Furthermore, the potential for vibrations and dynamic loads must be taken into account to prevent any potential resonance issues. Lastly, the fabrication, transportation, and erection of the long-span steel beams should be carefully planned to ensure feasibility and cost-effectiveness.

- Q: How do you calculate the bearing capacity of a steel I-beam?

- To calculate the bearing capacity of a steel I-beam, there are several factors that need to be considered. Firstly, you need to know the dimensions and properties of the I-beam, such as its height, width, and thickness. These measurements are typically provided by the manufacturer or can be obtained through physical measurements. Next, you need to determine the material properties of the steel used in the I-beam. This includes the yield strength, which is the maximum stress the material can withstand without permanent deformation, and the modulus of elasticity, which measures the stiffness of the material. Once you have these measurements and properties, you can use various formulas and calculations to determine the bearing capacity of the I-beam. One commonly used calculation is the Euler's buckling formula, which considers the compressive strength of the I-beam. Another important factor to consider is the load applied to the I-beam. This can include both dead loads, such as the weight of the structure it supports, and live loads, such as the weight of people or machinery. The load distribution and location of the load also play a role in determining the bearing capacity. It is important to note that calculating the bearing capacity of a steel I-beam requires expertise in structural engineering. It is recommended to consult with a professional engineer or use specialized software to accurately determine the bearing capacity and ensure structural safety.

- Q: Can steel I-beams be used in coastal areas?

- Indeed, coastal areas can indeed utilize steel I-beams. Steel, as a construction material, boasts durability and reliability, enabling it to endure the challenging conditions frequently encountered in coastal environments, such as strong winds, saltwater, and humidity. Nevertheless, it is crucial to carefully choose the suitable steel variant and employ protective coatings to avert corrosion. Stainless steel or galvanized steel are typically employed in coastal regions owing to their ability to resist rust and corrosion. Furthermore, consistent inspection and maintenance are imperative to guarantee the structural soundness of the steel I-beams utilized in coastal areas.

- Q: Can steel I-beams be used in the construction of hotels and resorts?

- Yes, steel I-beams can be commonly used in the construction of hotels and resorts. Steel I-beams provide strong structural support, making them ideal for large, multi-story buildings. Their high load-bearing capacity and versatility allow for efficient construction of various hotel and resort designs. Additionally, steel's durability and resistance to fire and pests make it a reliable choice for long-lasting and safe structures.

- Q: Cantilever scaffold of the I-beam, in the Yang Kok position encountered a frame column, what should I do?

- In fact, this should be good to deal with, if there are plans to say that.Cantilever structure encountered structural column, can be considered to be cantilevered into simply supported, namely the constructional column embedded corbel, the distal cantilevered on the bracket, the cantilever is more favorable, the original cantilever beam into force, better.

- Q: How are steel I-beams protected against corrosion?

- Steel I-beams are protected against corrosion through various methods, such as galvanization, painting, or applying protective coatings. Galvanization involves coating the steel with a layer of zinc, which acts as a sacrificial barrier, preventing corrosion from reaching the steel. Painting involves applying a layer of paint that acts as a barrier against moisture and oxygen, preventing corrosion. Additionally, protective coatings can be applied to steel I-beams, which provide an extra layer of protection against corrosion. These methods help to prolong the lifespan and integrity of steel I-beams in various applications.

Send your message to us

I Beam Steel IPEAA Type Used for Mineral Site with Light Weight

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 1000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords