HR Steel Equal Beams with High Quality Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Description:

1.Standards:GB,ASTM,BS,AISI,DIN,JIS

2.Length:6m,9m,12m

3.Material:GBQ235B,Q345BorEquivalent;ASTMA36;EN10025,S235JR,S355JR;JISG3192,SS400;SS540.

.

.

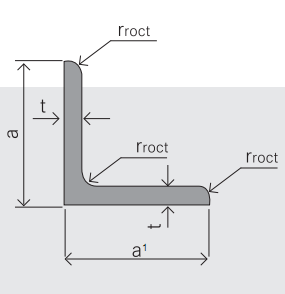

4.Sizes:

EQUAL ANGLES SIZES |

| ||

a(mm) | a1(mm) | thickness(mm) | length |

25 | 25 | 2.5---3.0 | 6M/12M |

30 | 30 | 2.5---4.0 | 6M/12M |

38 | 38 | 2.5 | 6M/12M |

38 | 38 | 3.0---5.0 | 6M/12M |

40 | 40 | 3.0---6.0 | 6M/12M |

50 | 50 | 3 | 6M/12M |

50 | 50 | 3.7---6.0 | 6M/9M/12M |

60 | 60 | 5.0---6.0 | 6M/9M/12M |

63 | 63 | 6.0---8.0 | 6M/9M/12M |

65 | 65 | 5.0---8.0 | 6M/9M/12M |

70 | 70 | 6.0---7.0 | 6M/9M/12M |

75 | 75 | 5.0---10.0 | 6M/9M/12M |

80 | 80 | 6.0---10.0 | 6M/9M/12M |

90 | 90 | 6.0---10.0 | 6M/9M/12M |

100 | 100 | 6.0---12.0 | 6M/9M/12M |

120 | 120 | 8.0-12.0 | 6M/9M/12M |

125 | 125 | 8.0---12.0 | 6M/9M/12M |

130 | 130 | 9.0-12.0 | 6M/9M/12M |

140 | 140 | 10.0-16.0 | 6M/9M/12M |

150 | 150 | 10---15 | 6M/9M/12M |

160 | 160 | 10---16 | 6M/9M/12M |

180 | 180 | 12---18 | 6M/9M/12M |

200 | 200 | 14---20 | 6M/9M/12M |

5. Material details:

Alloy No | Grade | Element (%) | |||||

C | Mn | S | P | Si | |||

|

|

|

|

|

|

| |

Q235 | B | 0.12—0.20 | 0.3—0.7 | ≤0.045 | ≤0.045 | ≤0.3 | |

|

|

|

|

|

|

| |

Alloy No | Grade | Yielding strength point( Mpa) | |||||

Thickness (mm) | |||||||

≤16 | >16--40 | >40--60 | >60--100 | ||||

≥ | |||||||

|

|

|

|

|

| ||

Q235 | B | 235 | 225 | 215 | 205 | ||

Alloy No | Grade | Tensile strength (Mpa) | Elongation after fracture (%) | ||||

Thickness (mm) | |||||||

| ≤16 | >16--40 | >40--60 | >60--100 | |||

≥ | |||||||

|

|

|

|

|

|

| |

Q235 | B | 375--500 | 26 | 25 | 24 | 23 | |

Usage & Applications:

Trusses;

Transmission towers;

Telecommunication towers;

Bracing for general structures;

Stiffeners in structural use.

Packaging & Delivery:

1. Transportation: the goods are delivered by truck from mill to loading port, the maximum quantity can be loaded is around 40MTs by each truck. If the order quantity cannot reach the full truck loaded, the transportation cost per ton will be little higher than full load.

2. With bundles and load in 20 feet/40 feet container, or by bulk cargo, also we could do as customer's request.

3. Marks:

Color mark: There will be color marking on both end of the bundle for the cargo delivered by bulk vessel. That makes it easily to distinguish at the destination port.

Tag mark: There will be tag mark tied up on the bundles. The information usually including supplier logo and name, product name, made in China, shipping marks and other information request by the customer.

If loading by container the marking is not needed, but we will prepare it as customer request.

FAQ:

Q1: Why buy Materials & Equipment from OKorder.com?

A1: All products offered byOKorder.com are carefully selected from China's most reliable manufacturing enterprises. Through its ISO certifications, OKorder.com adheres to the highest standards and a commitment to supply chain safety and customer satisfaction.

Q2: How do we guarantee the quality of our products?

A2: We have established an advanced quality management system which conducts strict quality tests at every step, from raw materials to the final product. At the same time, we provide extensive follow-up service assurances as required.

Q3: How soon can we receive the product after purchase?

A3: Within three days of placing an order, we will begin production. The specific shipping date is dependent upon international and government factors, but is typically 7 to 10 workdays.

Images:

- Q: How do steel I-beams contribute to the overall stability and strength of a structure?

- Steel I-beams contribute to the overall stability and strength of a structure in several ways. Firstly, their unique shape, which resembles the letter "I," provides exceptional resistance to bending forces. This means that I-beams are capable of supporting heavy loads and distributing them evenly across their length, minimizing the risk of sagging or collapsing. Moreover, the use of steel as the material for I-beams adds to their strength. Steel is known for its high tensile strength, meaning it can resist stretching or breaking under heavy loads. This attribute allows I-beams to withstand significant pressure without deforming or failing, ensuring the structural integrity of the entire building. Additionally, the design of I-beams allows for efficient use of materials. The top and bottom flanges of the beam are wider and thicker than the vertical web in the center. This configuration maximizes the beam's resistance to bending forces while minimizing the weight of the overall structure. The lightweight nature of steel I-beams makes them easier to handle during construction, reducing costs and labor requirements. Furthermore, the versatility of steel I-beams contributes to the overall stability of a structure. Engineers can adjust the size and shape of the beams according to the specific requirements of the building, ensuring optimal performance and load-bearing capacity. This flexibility allows for the creation of complex architectural designs while maintaining structural integrity. In summary, steel I-beams provide significant contributions to the overall stability and strength of a structure. Their unique shape, high tensile strength, efficient material usage, and versatility make them an indispensable component in modern construction, enabling buildings to withstand heavy loads and ensure the safety of their occupants.

- Q: Can Steel I-Beams be used for mezzanine storage?

- Yes, steel I-beams can be used for mezzanine storage. Steel I-beams are commonly used in construction for their strength and load-bearing capabilities. They are ideal for supporting heavy loads and can withstand the weight of a mezzanine structure and the items stored on it. The I-beams can be securely bolted or welded into place to provide a stable and sturdy base for the mezzanine floor. Additionally, steel I-beams can be customized to meet specific design requirements and can be easily integrated into existing structures. Overall, steel I-beams are a reliable and efficient choice for supporting mezzanine storage systems.

- Q: How do you transport and store steel I-beams?

- Careful planning and adherence to safety guidelines are essential when it comes to transporting and storing steel I-beams. Below, you will find the steps involved in this process: 1. Select the appropriate mode of transportation: Typically, steel I-beams are transported using flatbed trucks or trailers. It is important to ensure that the chosen vehicle has the capacity to safely carry the weight and size of the I-beams. 2. Secure the I-beams for transport: Prior to loading the I-beams onto the vehicle, it is crucial to secure them properly to prevent any movement during transit. To achieve this, use robust straps, chains, or clamps to secure the I-beams to the flatbed. Ensure that they are evenly distributed and balanced. 3. Determine weight restrictions and comply with regulations: Familiarize yourself with the weight restrictions and regulations governing the transportation of goods in your area. It is important to ensure that the combined weight of the I-beams, vehicle, and any additional equipment falls within the permitted limits. 4. Arrange for specialized equipment if necessary: In the event that the I-beams are too long or heavy to be loaded or unloaded manually, you may need to make arrangements for specialized equipment such as cranes or forklifts. Take care to choose equipment that is suitable for the weight and size of the I-beams. 5. Store the I-beams in a controlled environment: If you need to store the I-beams for an extended period, it is crucial to protect them from environmental factors that could cause corrosion or damage. Store them in a covered and dry area to shield them from rain, snow, or excessive humidity. 6. Properly stack and support the I-beams: When storing the I-beams, stack them in a manner that ensures stability and prevents any bending or warping. Employ wooden or steel pallets to provide support for the I-beams and distribute the weight evenly. 7. Perform regular inspections and maintenance on the stored I-beams: It is important to periodically inspect the stored I-beams to ensure they remain in good condition. Look out for signs of corrosion, damage, or deformation. If any issues are detected, take appropriate measures to prevent further deterioration. Always remember to adhere to local regulations and safety guidelines when transporting and storing steel I-beams. Seeking advice from professionals or experienced individuals in the steel industry can provide valuable insights and guidance for a safe and efficient process.

- Q: What are the common methods of installing steel I-beams in existing structures?

- The common methods of installing steel I-beams in existing structures include using temporary supports, removing a portion of the existing structure, placing the I-beam in position, and then securing it with bolts or welding. Another method involves using a crane to lift the I-beam into place, followed by attaching it to the existing structure using welding or bolting techniques.

- Q: Can steel I-beams be used for airport terminals?

- Indeed, airport terminals can utilize steel I-beams for their construction. The strength and load-bearing abilities of steel I-beams are widely recognized, making them a common choice for various construction projects. Considering airport terminals' substantial size and need for extensive spans and high load capacities, employing steel I-beams proves advantageous. These beams can effectively sustain the weight of the terminal's roof, walls, and other structural components, guaranteeing a steadfast and enduring edifice. Moreover, steel I-beams can be customized into diverse dimensions and configurations, affording flexibility in both design and construction. The adaptability and robustness of steel I-beams render them an appropriate alternative for airport terminals.

- Q: What is the cost of steel I-beams compared to other structural materials?

- The cost of steel I-beams is generally higher compared to other structural materials such as wood or concrete. However, steel I-beams offer superior strength, durability, and versatility, making them a preferred choice for many construction projects despite their higher cost.

- Q: Can steel I-beams be used in marine environments?

- Yes, steel I-beams can be used in marine environments. However, it is important to use corrosion-resistant materials like stainless steel or galvanized steel to prevent rust and degradation due to exposure to saltwater and other harsh elements. Regular maintenance and proper coatings are necessary to prolong their lifespan in marine environments.

- Q: Can steel I-beams be used for industrial manufacturing facilities?

- Steel I-beams, due to their strength, durability, and versatility, are frequently employed in industrial manufacturing facilities. These beams possess the ability to bear heavy loads and are commonly utilized as structural supports in factories and warehouses. They ensure stability and withstand the rigorous conditions commonly encountered in industrial environments, including high temperatures, heavy machinery, and continuous vibrations. Moreover, steel I-beams can be conveniently fabricated, enabling efficient customization and assembly in diverse manufacturing layouts.

- Q: How do you determine the spacing and placement of steel I-beams in a structure?

- The spacing and placement of steel I-beams in a structure are determined by a combination of engineering calculations and design considerations. Factors such as the load-bearing requirements, span of the beams, structural design codes, and the type of construction play a crucial role in determining the appropriate spacing and placement. Engineers analyze the structural loads and forces acting on the beams, considering factors like dead loads, live loads, wind loads, and seismic loads. They also consider the size and weight of the beams, as well as any constraints imposed by architectural, mechanical, or other elements of the structure. By carefully analyzing these factors and performing structural calculations, engineers can determine the optimal spacing and placement of steel I-beams to ensure the structural integrity and safety of the building or structure.

- Q: Can steel I-beams be used in data centers or technology facilities?

- Yes, steel I-beams can be used in data centers or technology facilities. Steel I-beams are commonly used in construction due to their high strength and durability. In data centers and technology facilities, where heavy equipment such as servers and storage racks are installed, steel I-beams can provide the necessary structural support to handle the weight and load of the equipment. Furthermore, steel I-beams offer various advantages for data centers and technology facilities. They have a high load-bearing capacity, which means they can support heavy loads without flexing or bending. This is crucial for ensuring the stability and safety of the facility. Steel I-beams are also fire-resistant, which is crucial in data centers where the risk of fire can have catastrophic consequences. The fire-resistant properties of steel I-beams can help prevent the collapse of the structure and provide additional time for evacuation or firefighting efforts. Additionally, steel I-beams can be designed and engineered to meet specific requirements and load capacities. This flexibility allows for customization and optimization of the structural design, ensuring that the data center or technology facility can accommodate the specific needs and equipment configurations. Overall, steel I-beams are a reliable and commonly used structural element in data centers and technology facilities due to their strength, durability, fire resistance, and flexibility in design.

Send your message to us

HR Steel Equal Beams with High Quality Made in China

- Loading Port:

- Tianjin

- Payment Terms:

- TT or LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 100000 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords