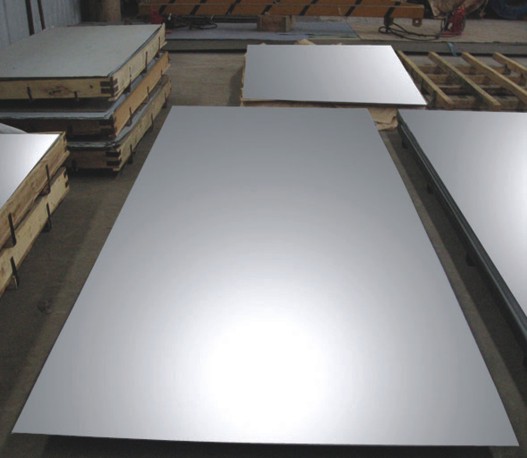

Stainless Steel Sheet 8K Surface Treatment 0.7mmx1220mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

You Might Also Like

Product Introduction of Stainless Steel Sheet 8K Surface Treatment 0.7mmx1220mmx2440mm:

Our Stainless Steel products including the stainless steel sheet/plate, stainless steel coil, stainless steel rod/bar, stainless steel angle, stainless steel strip, stainless steel flat, carbon steel products and alloy steel materials. It also can supply the processing of surface, like No.4, BA, HL, SB, 8K, and so on.

Loading Quantity of Stainless Steel Sheet 8K Surface Treatment 0.7mmx1220mmx2440mm: 25 Tons/20FCL.

Grade of Stainless Steel Sheet 8K Surface Treatment 0.7mmx1220mmx2440mm: 201, 306, 316 Etc.

Delivery Time of Stainless Steel Sheet 8K Surface Treatment 0.7mmx1220mmx2440mm: 20 days Per Container.

Application of Stainless Steel Sheet 8K Surface Treatment 0.7mmx1220mmx2440mm:

| Finish | Thickness | Characteristics | Applications |

| No. 1 | 3.0mm~50.0mm | Finished by hot-rolling, annealing and pickling, characterized by white pickled surface | Chemical industry equipment, Industrial tanks |

| No. 2B | 0.3mm~6.0mm | Finished by heat treatment, pickling after cold rolling, followed by skin pass line to be more brighter and smooth surface | General Application Medical Instruments,Tableware |

| No. BA (Bright Annealed) | 0.5mm~2.0mm | Bright heat treatment after cold rolling | Kitchen utensil, kitchen ware,architectural purpose |

| No. 4 | 0.4mm~3.0mm | Polishing with No. 150 to No.180 mesh abrasivesThe most popular finishes | Milk & Food processing acilities, Hospital Equipment, Bath-tub |

| HL(Hair Line) | 0.4mm~3.0mm | Finished by continuous linear polishing | Architectural purposes, escalators, kitchen ware vehicles |

FAQ

Q: CAN YOU PROVIDE MILL TEST CERTIFICATE?

A: YES! Mill Test Certificate for Stainless Steel Sheet 8K Surface Treatment 0.7mmx1220mmx2440mm are available.

Q: CAN YOU MAKE DDQ (DEEP DRAWING QUALITY)?

A: YES. Our material has been widely used for producing Stainless Steel Pots and Stainless Steel Sinks, which have strict request for good deep drawing quality.

Q: HOW TO GET A SAMPLE?

A: FREE samples for HiStainless Steel Sheet 8K Surface Treatment 0.7mmx1220mmx2440mm are available for your checking and testing. And to get free samples, you need to send us you detailed receiving address (including post code) and your DHL/FedEx/UPS account for collecting samples, courier cost will be paid in your side.

- Q: Can stainless steel sheets be used for wall cladding?

- Certainly! Wall cladding can indeed utilize stainless steel sheets. This material, known for its durability and resistance to corrosion, proves to be a fitting selection for cladding purposes. Its sleek and contemporary appearance enhances the aesthetic appeal of walls. Furthermore, stainless steel sheets are effortless to install and maintain, rendering them an exceptional choice for both indoor and outdoor walls. Moreover, they possess remarkable fire resistance and can endure high temperatures, guaranteeing a secure option for wall cladding.

- Q: 1cm thick 201 stainless steel plate how much money party

- 1 thick 201 stainless steel sheet, 95 yuan / square meters.Stainless steel (Stainless Steel) is stainless acid resistant steel abbreviation, resistant to air, steam

- Q: Can stainless steel sheets be used for automotive exhaust systems?

- Indeed, automotive exhaust systems can utilize stainless steel sheets. The use of stainless steel is prevalent in exhaust systems owing to its remarkable resistance to corrosion, ability to withstand high temperatures, and durability. It successfully endures the harsh conditions present in exhaust systems, encompassing intense heat, moisture, and chemicals. Stainless steel sheets can be shaped and manufactured into diverse components of the exhaust system, including pipes, mufflers, and catalytic converters. They offer enduring performance, minimize the likelihood of rust and corrosion, and enhance the overall efficiency and longevity of the automotive exhaust system.

- Q: How do you prevent fingerprints on stainless steel sheets?

- There are several steps you can take to prevent fingerprints on stainless steel sheets: 1. Start by thoroughly cleaning the surface of the stainless steel sheets using a mild detergent or stainless steel cleaner. This will eliminate any existing fingerprints or smudges. 2. When handling the sheets, wear gloves to avoid transferring natural oils from your hands onto the surface. Cotton or nitrile gloves are recommended as they offer a good grip and leave no residue. 3. Minimize direct contact with the stainless steel surface as much as possible. This can be achieved by using specialized tools or wearing gloves when handling and installing the sheets. 4. Consider applying a protective coating specifically designed for stainless steel. These coatings create a barrier that repels fingerprints and simplifies the cleaning process. Be sure to follow the manufacturer's instructions for proper application. 5. Use a soft microfiber cloth when cleaning the stainless steel sheets. Microfiber is gentle on the surface and helps prevent streaks and fingerprints. Avoid using abrasive materials or rough scrubbers that can damage the stainless steel finish. 6. Establish a regular cleaning routine to remove any fingerprints or smudges that may appear over time. Dilute a mild detergent in warm water and use a soft cloth or sponge to wipe down the stainless steel sheets. Rinse with clean water and thoroughly dry. By following these preventive measures and cleaning techniques, you can significantly reduce the visibility of fingerprints on stainless steel sheets and keep them looking clean and flawless.

- Q: How do I prevent discoloration on stainless steel sheets?

- To avoid discoloration on stainless steel sheets, there are several steps you can take: 1. Keep them clean: Make sure to clean stainless steel sheets on a regular basis using mild soap or a dedicated stainless steel cleaner. Steer clear of abrasive cleaners or scrub brushes, as they can scratch the surface and make it more susceptible to discoloration. 2. Steer clear of harsh chemicals: Avoid using harsh chemicals, bleach, or cleaners containing chlorine on stainless steel sheets, as they can lead to discoloration. If any spills occur, clean them up immediately to prevent staining. 3. Ensure proper ventilation: It is crucial to have adequate ventilation in the area where the stainless steel sheets are installed. This is particularly important in spaces where chemicals or fumes are present, as they can react with the stainless steel and cause discoloration. 4. Apply protective coatings: Consider applying a protective coating to the stainless steel sheets to help prevent discoloration. There are various protective coatings available on the market that are specifically designed for stainless steel. These coatings create a barrier between the steel and external factors, reducing the likelihood of discoloration. 5. Perform regular maintenance: Regularly inspect the stainless steel sheets for any signs of discoloration or damage. Address any issues promptly to prevent further deterioration. By implementing these preventive measures, you can reduce the risk of discoloration on stainless steel sheets and maintain their aesthetic appeal for an extended period of time.

- Q: How do I determine the hardness of stainless steel sheets?

- To determine the hardness of stainless steel sheets, there are a few methods you can use. One common method is the Rockwell hardness test, which measures the depth of penetration of an indenter into the material. The Rockwell scale has different scales depending on the material, so you will need to use the appropriate scale for stainless steel. To perform the Rockwell hardness test, you will need a Rockwell hardness tester and a diamond or tungsten carbide indenter. Start by placing the stainless steel sheet on a flat, stable surface. Then, position the indenter on the surface of the sheet and apply a minor load. Once the minor load is applied, proceed to apply the major load until it reaches its maximum value. Once the load has been applied and released, the hardness value will be displayed on the Rockwell hardness tester's dial or digital display. This value corresponds to a specific hardness scale, such as HRC for stainless steel. It is important to note that the Rockwell hardness test provides a relative measurement of hardness and does not necessarily reflect the material's physical properties. Additionally, the hardness of stainless steel can vary depending on factors such as the alloy composition, heat treatment, and manufacturing process. Therefore, it is recommended to consult the material's specifications or conduct additional tests to obtain more accurate and comprehensive information about the stainless steel sheet's hardness.

- Q: Can stainless steel sheets be used for food processing equipment?

- Yes, stainless steel sheets can be used for food processing equipment. Stainless steel is a popular choice for equipment used in the food processing industry due to its excellent corrosion resistance, durability, and hygienic properties. It is resistant to staining, rust, and chemical damage, making it suitable for contact with food and cleaning agents. Stainless steel sheets are also easy to clean and maintain, reducing the risk of contamination. Additionally, stainless steel is non-reactive, meaning it does not interact with food or alter its taste, ensuring the safety and quality of processed food.

- Q: How do stainless steel sheets compare to other types of metal sheets?

- Stainless steel sheets possess numerous advantages that distinguish them from alternative metal sheets. Firstly, stainless steel exhibits a high level of resistance to corrosion, rendering it an optimal selection for applications where durability and longevity are of utmost importance. Unlike other metals, stainless steel does not readily rust or stain, thereby guaranteeing the preservation of its appearance and functionality even in challenging environments. Secondly, stainless steel sheets are renowned for their strength and robustness. They possess a significant tensile strength, enabling them to endure heavy loads without undergoing bending or warping. This attribute renders stainless steel sheets suitable for a wide array of applications, including the construction, automotive, and manufacturing industries. Another notable advantage of stainless steel sheets lies in their hygienic properties. Stainless steel is non-porous and non-absorbent, facilitating easy cleaning and maintenance. Additionally, it exhibits resistance to bacterial growth, making it a favored choice for medical equipment, food processing facilities, and kitchen appliances. Furthermore, stainless steel sheets offer exceptional heat resistance. They can withstand high temperatures without compromising their structural integrity or developing any deformities, making them suitable for applications involving extreme heat or thermal cycling. Lastly, stainless steel sheets are available in a variety of finishes and textures, granting versatility in terms of design options. Whether one prefers a polished, brushed, or matte finish, stainless steel allows for customization to fulfill any aesthetic requirement. In conclusion, stainless steel sheets surpass other types of metal sheets due to their exceptional resistance to corrosion, strength, hygienic properties, heat resistance, and aesthetic versatility. These qualities establish stainless steel sheets as the preferred choice for numerous industries, ensuring durability, reliability, and longevity across various applications.

- Q: Are stainless steel sheets good for high-temperature applications?

- Yes, stainless steel sheets are excellent for high-temperature applications. Stainless steel has a high melting point, typically ranging from 1400 to 1450 degrees Celsius (2552 to 2642 degrees Fahrenheit), making it suitable for use in environments with elevated temperatures. Additionally, stainless steel exhibits excellent resistance to oxidation at high temperatures, which helps prevent the formation of scales or rust that can weaken the material. It also has good thermal conductivity, allowing for efficient heat transfer. These properties make stainless steel sheets a reliable choice for a wide range of high-temperature applications, including industrial furnaces, heat exchangers, boilers, and exhaust systems.

- Q: What are the different types of embossed finishes available for stainless steel sheets?

- There are several different types of embossed finishes available for stainless steel sheets. Some of the most common ones include: 1. Diamond pattern: This is one of the most popular embossed finishes for stainless steel sheets. It features a raised diamond pattern that adds a decorative touch to the surface. 2. Linen pattern: The linen embossed finish creates a textured surface that resembles the look and feel of linen fabric. It adds depth and visual interest to the stainless steel sheet. 3. Leather pattern: The leather embossed finish is designed to mimic the look of genuine leather. It creates a textured surface that adds a unique and stylish touch to the stainless steel sheet. 4. Bead pattern: The bead embossed finish features a raised, rounded pattern that resembles beads. This finish adds a subtle decorative element to the stainless steel sheet. 5. Checker pattern: The checker embossed finish consists of raised squares or rectangles arranged in a checkerboard pattern. This finish adds a modern and stylish look to the stainless steel sheet. 6. Hammered pattern: The hammered embossed finish creates a textured surface that resembles the marks left by a hammer. It adds a rustic and handcrafted aesthetic to the stainless steel sheet. These are just a few examples of the different types of embossed finishes available for stainless steel sheets. Each finish offers a unique look and texture, allowing you to choose the one that best suits your design preferences and application requirements.

Send your message to us

Stainless Steel Sheet 8K Surface Treatment 0.7mmx1220mmx2440mm

- Loading Port:

- Shanghai

- Payment Terms:

- TT OR LC

- Min Order Qty:

- 25 m.t.

- Supply Capability:

- 2500 m.t./month

OKorder Service Pledge

OKorder Financial Service

Similar products

Hot products

Hot Searches

Related keywords